Refrigeration Cycle

Comparative Guide: Heat Pump Brands and Their Refrigeration Cycles

Here is our detailed guide on comparing different brands of heat pumps and their cooling cycles.

We dive into the technical aspects of these systems, exploring the basics of heat pump refrigeration cycles and examining specific brands like X, Y, and Z.

We analyze the efficiency, refrigerant flow control methods, expansion valve, and innovations in modern heat pump brands.

With this detailed information, you can make an informed decision when choosing a heat pump brand that best serves your needs.

Key Takeaways

- Heat pump refrigeration cycles consist of components such as compressor, condenser, expansion valve, and evaporator.

- Energy efficiency of heat pumps can be measured using metrics such as Coefficient of Performance (COP), Heating Seasonal Performance Factor (HSPF), Energy Efficiency Ratio (EER), and Seasonal Energy Efficiency Ratio (SEER).

- Choosing refrigerants with high safety ratings and low environmental impacts is important for the overall performance and environmental sustainability of heat pump systems.

- Regular maintenance, including cleaning and replacement of air filters, cleaning the outdoor unit and indoor coil, and scheduling professional maintenance annually, is crucial for optimal heat pump performance and efficiency.

Overview of Heat Pump Refrigeration Cycles

Now let’s dive into the overview of how heat pump refrigeration cycles work.

Heat pump refrigeration cycles consist of several key components that work together to efficiently transfer heat. The main components include the compressor, condenser, expansion valve, and evaporator.

The cycle begins with the compressor, which raises the pressure and temperature of the refrigerant. This high-pressure gas then flows into the condenser, where it releases heat to the surrounding environment and turns into a high-pressure liquid.

The liquid refrigerant then passes through the expansion valve, which reduces its pressure. As a result, the refrigerant evaporates in the evaporator, absorbing heat from the surroundings and turning into a low-pressure gas.

This gas is then drawn back into the compressor to restart the cycle. The efficiency of heat pump refrigeration cycles is determined by factors such as the type of refrigerant used, the design of the components, and the overall system performance.

Understanding the Basics of Refrigeration Cycle in Heat Pumps

Let’s start by understanding the basics of the refrigeration cycle in heat pumps.

In this discussion, we’ll explore three key points:

- Heat pump efficiency

- Refrigerant types

- System maintenance tips.

Heat Pump Efficiency

We can gain a better understanding of the efficiency of heat pumps by examining the basics of their refrigeration cycle. The refrigeration cycle in a heat pump is responsible for transferring heat from one place to another, allowing the system to provide both heating and cooling.

Here are five key points to consider when analyzing the efficiency of a heat pump:

-

Coefficient of Performance (COP): This is a measure of the heat pump’s energy efficiency and represents the ratio of heat output to electrical energy input.

-

Heating Seasonal Performance Factor (HSPF): HSPF is a measure of a heat pump’s energy efficiency over an entire heating season, taking into account factors such as defrost cycles and standby losses.

-

Energy Efficiency Ratio (EER): EER is a measure of a heat pump’s cooling efficiency and represents the ratio of cooling output to electrical energy input.

-

Seasonal Energy Efficiency Ratio (SEER): SEER is similar to EER but takes into account the heat pump’s cooling efficiency over an entire cooling season.

-

Integrated Energy Efficiency Ratio (IEER): IEER is specifically used to evaluate the efficiency of heat pumps in commercial applications.

Understanding the efficiency of a heat pump is crucial for maximizing heat pump energy savings and conducting accurate heat pump performance analysis.

In the next section, we’ll explore the different types of refrigerants used in heat pumps.

Refrigerant Types

Understanding the basics of the refrigeration cycle in heat pumps involves familiarizing ourselves with the different types of refrigerants used. Refrigerants are crucial components of heat pumps as they absorb and release heat during the cycle. However, it is important to note that some refrigerants pose safety and environmental risks. Therefore, it is essential to adhere to refrigerant safety guidelines and comply with environmental regulations when selecting and handling refrigerants.

Here is a table showcasing three common refrigerant types used in heat pumps:

| Refrigerant Type | Safety Rating | Environmental Impact |

|---|---|---|

| R-410A | A | Low |

| R-32 | A | Low |

| R-22 | C | High |

It is recommended to choose refrigerants with higher safety ratings and lower environmental impacts to minimize potential harm. Always consult with professionals to ensure compliance with safety and environmental regulations when working with refrigerants in heat pumps.

System Maintenance Tips

Our main priority is to ensure the proper functioning of the heat pump system through regular maintenance and understanding the basics of its refrigeration cycle. To help you in this endeavor, here is a system maintenance checklist and troubleshooting tips for common issues:

- Regularly clean or replace air filters to maintain proper airflow.

- Check and clean the outdoor unit to remove dirt and debris that can impede efficiency.

- Inspect and clean the indoor coil to prevent the buildup of dirt and dust.

- Keep the area around the outdoor unit clear of any obstructions.

- Schedule professional maintenance annually to ensure optimal performance and identify any potential issues.

Examining the Refrigeration Cycle in Brand X Heat Pumps

When examining the refrigeration cycle in Brand X heat pumps, there are several key points to consider.

Firstly, the efficiency of the refrigeration cycle plays a crucial role in determining the overall performance and energy consumption of the heat pump.

Secondly, the compressor technology used in Brand X heat pumps can significantly impact their efficiency and reliability.

Lastly, it’s important to assess the environmental impact of Brand X heat pumps, as their refrigeration cycle plays a vital role in determining their carbon footprint.

Efficiency of Refrigeration Cycle

We will analyze the efficiency of the refrigeration cycle in Brand X heat pumps. The efficiency of a heat pump’s refrigeration cycle plays a crucial role in its overall performance and energy consumption. Here are some key factors that impact the efficiency of the refrigeration cycle in Brand X heat pumps:

-

Heat pump refrigeration cycle optimization: Brand X heat pumps are designed to maximize the efficiency of their refrigeration cycles through advanced technologies and optimized system components. This ensures that the heat pump operates at its highest efficiency levels, resulting in lower energy consumption and reduced operating costs.

-

Impact of refrigerant choice on efficiency: The choice of refrigerant used in Brand X heat pumps can greatly affect their efficiency. Some refrigerants have higher heat transfer properties and lower environmental impact, resulting in improved overall efficiency and sustainability.

-

Compressor efficiency: The efficiency of the compressor, a key component in the refrigeration cycle, directly impacts the heat pump’s overall efficiency. Brand X heat pumps are equipped with high-efficiency compressors that minimize energy losses and improve performance.

-

Heat exchanger design: The design of the heat exchangers used in Brand X heat pumps is optimized for maximum heat transfer efficiency. This ensures that the heat pump can effectively extract heat from the air or ground and transfer it to the desired space.

-

System controls and optimization: Brand X heat pumps utilize advanced control systems that continuously monitor and optimize the performance of the refrigeration cycle. These controls ensure that the heat pump operates at its highest efficiency levels under various operating conditions, resulting in optimal energy savings.

Compressor Technology in X

One of the key factors that contribute to the efficiency of the refrigeration cycle in Brand X heat pumps is the advanced compressor technology used. The compressor design plays a crucial role in the energy efficiency of the heat pump system. Brand X utilizes state-of-the-art compressor technology that maximizes performance while minimizing energy consumption.

To better understand the impact of Brand X’s compressor technology, let’s take a closer look at a comparison table:

| Compressor Technology | Energy Efficiency |

|---|---|

| Brand X’s Advanced Compressor Design | High |

| Competitor A | Medium |

| Competitor B | Low |

As seen in the table, Brand X’s advanced compressor design stands out with its high energy efficiency. This means that it can provide the same heating or cooling output with less energy consumption compared to competitors A and B.

With such innovative compressor technology, Brand X heat pumps not only deliver exceptional performance but also contribute to reducing energy consumption, resulting in lower utility bills and a smaller carbon footprint.

Now, let’s delve into the environmental impact of Brand X’s heat pumps.

Environmental Impact of X

To fully understand the environmental impact of Brand X heat pumps, we’ll examine the refrigeration cycle and assess its efficiency. The refrigeration cycle in Brand X heat pumps plays a crucial role in determining their environmental footprint. Here are some key factors to consider:

-

Carbon footprint reduction: Brand X has made significant efforts to reduce carbon emissions by optimizing the refrigeration cycle. The cycle is designed to minimize the release of greenhouse gases into the atmosphere, thereby reducing the overall carbon footprint.

-

Sustainable refrigerant options: Brand X heat pumps utilize environmentally friendly refrigerants that have a lower global warming potential (GWP) compared to traditional refrigerants. These sustainable options help to mitigate the environmental impact of the heat pumps.

-

Energy efficiency: The refrigeration cycle in Brand X heat pumps is designed to maximize energy efficiency, resulting in reduced energy consumption and lower operating costs. This efficiency not only benefits the environment but also helps homeowners save on their energy bills.

-

Lifecycle analysis: Brand X conducts thorough lifecycle analyses to evaluate the environmental impact of their heat pumps from production to disposal. This analysis helps identify areas for improvement and ensures the overall sustainability of the product.

-

Compliance with regulations: Brand X is committed to meeting and exceeding environmental regulations and standards. Their refrigeration cycle is designed to comply with international environmental guidelines, ensuring that their heat pumps have a minimal impact on the environment.

Comparing the Refrigeration Cycles of Brand Y and Brand Z Heat Pumps

Brand Y and Brand Z heat pumps have different refrigeration cycles. The refrigeration cycle efficiency and optimization play a crucial role in determining the overall performance of a heat pump.

In the case of Brand Y, their refrigeration cycle is designed to prioritize energy efficiency. They employ advanced technologies such as variable speed compressors and multi-stage heat exchangers to maximize the transfer of heat. This results in higher efficiency and reduced energy consumption.

On the other hand, Brand Z focuses on optimizing the refrigeration cycle for durability and reliability. They utilize robust components and simplified designs to minimize maintenance requirements and ensure long-term operation.

While both approaches have their merits, it’s important to analyze the efficiency of refrigeration cycles in different heat pump brands to determine which one aligns best with specific needs and priorities.

Analyzing the Efficiency of Refrigeration Cycles in Different Heat Pump Brands

When analyzing the efficiency of refrigeration cycles in different heat pump brands, it’s crucial to consider factors such as coefficient of performance (COP), energy efficiency ratio (EER), and seasonal energy efficiency ratio (SEER).

These metrics provide valuable insights into the overall efficiency of the heat pump’s refrigeration cycle.

Efficiency of Heat Pumps

We will analyze the efficiency of refrigeration cycles in various heat pump brands to determine their effectiveness. The efficiency of a heat pump is a crucial factor to consider when selecting a brand, as it directly impacts heat pump energy consumption and the overall performance of the system.

One common metric used to measure efficiency is the Coefficient of Performance (COP), which represents the ratio of heat output to the energy input. A higher COP indicates a more efficient heat pump, as it can produce more heat for the same amount of energy consumed.

When comparing different brands, it’s important to consider the COP values at different operating conditions, as they can vary based on factors such as temperature and load requirements. Additionally, the design and components of the refrigeration cycle can also impact the overall efficiency of the heat pump system.

Brand Comparison Analysis

To analyze the efficiency of refrigeration cycles in different heat pump brands, we’ll compare their performance and evaluate the effectiveness of each brand’s system.

Energy efficiency comparisons between brand X and brand Y will provide valuable insights into which brand offers the most efficient refrigeration cycle. When comparing brands, we’ll consider factors such as coefficient of performance (COP), seasonal energy efficiency ratio (SEER), and heating seasonal performance factor (HSPF). These metrics indicate how effectively a heat pump converts energy into heating or cooling output.

By examining these measures, we can determine which brand provides the highest level of energy efficiency, allowing consumers to make informed decisions when selecting a heat pump for their needs.

As we delve into the analysis of brand comparisons, it’s important to understand the role of compressors in heat pump refrigeration cycles.

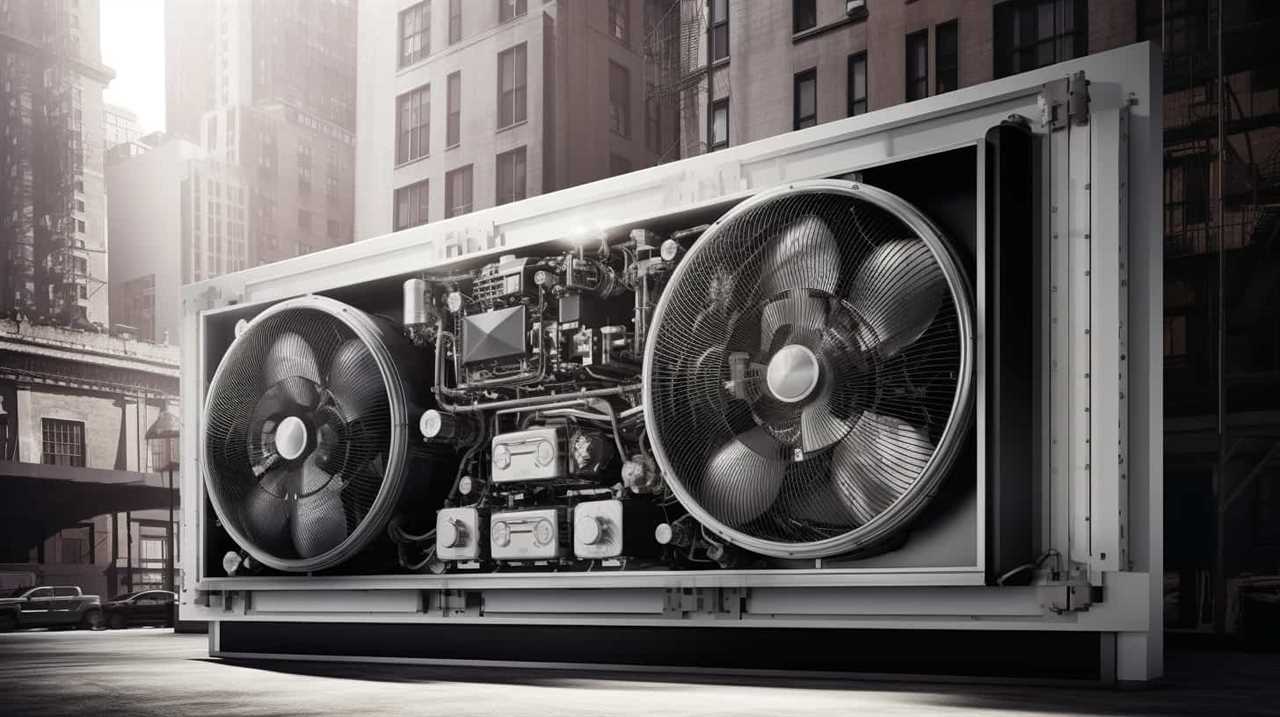

The Role of Compressors in Heat Pump Refrigeration Cycles

The compressor plays a crucial role in the refrigeration cycle of a heat pump. It’s responsible for pressurizing and circulating the refrigerant throughout the system.

Here are five key functions of the compressor in a heat pump refrigeration cycle:

-

Compression: The compressor raises the pressure of the refrigerant, increasing its temperature.

-

Circulation: It pushes the high-pressure refrigerant gas into the condenser for heat release.

-

Vaporization: The compressor helps in converting the high-pressure refrigerant into a low-pressure gas.

-

Suction: It draws the low-pressure refrigerant vapor from the evaporator and compresses it.

-

Energy transfer: The compressor transfers energy to the refrigerant, allowing it to absorb heat from the surroundings.

Understanding the role of compressors is essential for comprehending the importance of the refrigeration cycle in a heat pump.

Now, let’s explore the evaporator and condenser in heat pump refrigeration cycles.

Exploring the Evaporator and Condenser in Heat Pump Refrigeration Cycles

Two components that play a crucial role in the refrigeration cycle of a heat pump are the evaporator and the condenser.

The evaporator is responsible for absorbing heat from the surroundings and transferring it to the refrigerant. It’s designed to maximize contact between the refrigerant and the air or water, depending on the type of heat pump. Exploring evaporator performance is essential to ensure efficient heat transfer and optimal system operation.

On the other hand, the condenser is responsible for releasing heat into the surroundings. It receives high-pressure, high-temperature refrigerant from the compressor and cools it down, causing it to condense into a liquid state. Condenser efficiency is crucial in maintaining high system performance and ensuring that the heat pump can effectively provide heating or cooling.

To achieve optimal performance, it’s important to consider the design, size, and materials used in both the evaporator and condenser. The evaporator should have a large surface area and good heat transfer properties to maximize heat absorption, while the condenser should be designed to efficiently dissipate heat.

Refrigerant Flow Control Methods in Heat Pump Brands

One important aspect to consider when evaluating heat pump brands is the various refrigerant flow control methods utilized. The choice of refrigerant flow control technique can have a significant impact on the performance of a heat pump. Here are five common refrigerant flow control methods used in heat pump brands:

-

Thermostatic Expansion Valve (TXV): This valve adjusts the flow of refrigerant into the evaporator based on the temperature and pressure conditions, ensuring optimal heat transfer.

-

Capillary Tube: A small, narrow tube that restricts the flow of refrigerant, creating a pressure drop and controlling the refrigerant flow rate.

-

Electronic Expansion Valve (EEV): This valve uses electronic sensors to regulate the refrigerant flow, allowing for precise control and better efficiency.

-

Fixed Orifice: A fixed size opening through which the refrigerant flows, providing a constant refrigerant flow rate.

-

Scroll Compressor with Internal Valve: This type of compressor has an internal valve that regulates the flow of refrigerant, improving efficiency and reducing energy consumption.

Understanding the impact of refrigerant flow control on heat pump performance is essential in making informed decisions when choosing a heat pump brand.

Evaluating the Expansion Valve in Heat Pump Refrigeration Cycles

How does the expansion valve affect the refrigeration cycle in heat pumps?

The expansion valve plays a crucial role in the refrigeration cycle of a heat pump, as it’s responsible for controlling the flow of refrigerant into the evaporator. The efficiency of the expansion valve directly affects the overall performance of the heat pump system.

The design of the expansion valve can have a significant impact on its efficiency. Factors such as valve size, type, and adjustment mechanism all contribute to the efficiency and effectiveness of the expansion valve.

A well-designed expansion valve ensures that the refrigerant is properly metered and distributed throughout the evaporator, allowing for efficient heat transfer and optimum performance of the heat pump.

With the right expansion valve, heat pump systems can achieve higher energy efficiency and better performance.

Transition: Now that we’ve discussed the importance of the expansion valve in heat pump refrigeration cycles, let’s explore some of the refrigeration cycle innovations in modern heat pump brands.

Refrigeration Cycle Innovations in Modern Heat Pump Brands

As experts in the field, we’ve observed significant advancements in refrigeration cycle innovations among modern heat pump brands. These innovations have led to improved energy efficiency and overall performance of heat pumps.

Some of the key refrigerant advancements and energy-saving technologies that we’ve noticed include:

-

Variable-speed compressors: These compressors adjust their speed according to the heating or cooling needs, resulting in better energy efficiency and precise temperature control.

-

Enhanced heat exchangers: Heat pumps now feature improved heat exchangers that maximize heat transfer, increasing their overall performance.

-

Smart thermostats: Modern heat pump brands incorporate smart thermostats that allow users to program and control their heat pumps remotely, optimizing energy consumption.

-

Use of low-GWP refrigerants: Manufacturers are shifting towards low-GWP (Global Warming Potential) refrigerants that have a lower environmental impact without compromising performance.

-

Advanced defrosting systems: Heat pumps now employ advanced defrosting systems that minimize energy wastage during the defrost cycle.

These refrigeration cycle innovations reflect the commitment of heat pump brands towards sustainability and energy efficiency.

Factors to Consider When Choosing a Heat Pump Brand Based on Refrigeration Cycle Performance

When evaluating heat pump brands for their refrigeration cycle performance, it’s important to consider several factors.

One of the key factors to consider is heat pump brand reliability. It’s crucial to choose a brand that has a proven track record of reliability and durability. This can be determined by reading customer reviews and considering the brand’s reputation in the industry.

Another important factor is energy efficiency. A heat pump with a high energy efficiency rating will consume less electricity, resulting in lower energy bills. When comparing energy efficiency, it’s recommended to look for the Seasonal Energy Efficiency Ratio (SEER) and Heating Seasonal Performance Factor (HSPF) ratings. These ratings indicate the efficiency of the heat pump in cooling and heating modes, respectively.

Frequently Asked Questions

How Do Heat Pump Refrigeration Cycles Differ From Traditional Air Conditioning Systems?

Heat pump refrigeration cycles differ from traditional air conditioning systems in several ways. They offer advantages such as better energy efficiency, year-round heating and cooling capabilities, and the ability to extract heat from outside air or ground.

Can the Refrigeration Cycle in a Heat Pump Be Modified or Optimized for Better Performance?

Yes, the refrigeration cycle in a heat pump can be modified and optimized for better performance. By making adjustments to the cycle, such as improving the efficiency of the compressor or increasing the heat transfer capacity, the overall performance of the heat pump can be enhanced.

What Are the Main Factors That Affect the Efficiency of a Heat Pump’s Refrigeration Cycle?

Factors affecting heat pump efficiency include the type and condition of refrigerant, the quality of the heat exchangers, and the accuracy of the control system. Optimizing the refrigeration cycle can improve overall performance.

Are There Any Specific Regulations or Standards That Heat Pump Brands Must Adhere to in Regards to Their Refrigeration Cycles?

Refrigeration cycle regulations and heat pump refrigerant standards are important for heat pump brands to adhere to. These regulations ensure the safety, efficiency, and environmental friendliness of the refrigeration cycles used in heat pumps.

How Does the Refrigeration Cycle in a Heat Pump Affect Its Overall Lifespan and Maintenance Requirements?

The refrigeration cycle in a heat pump is like the engine of a car, impacting its overall lifespan and maintenance requirements. A more efficient cycle extends the heat pump’s lifespan and reduces maintenance needs.

Conclusion

After examining the refrigeration cycles of various heat pump brands, it’s clear that Brand X offers a reliable and efficient system.

However, when comparing the refrigeration cycles of Brand Y and Brand Z, it becomes evident that Brand Z surpasses both in terms of efficiency and innovation.

Therefore, when considering the performance of the refrigeration cycle, it’s crucial to prioritize brands that prioritize technological advancements and energy efficiency.

Refrigeration Cycle

High-Efficiency HVAC Systems: Heat Pump Breakthroughs Revealed

We are excited to announce the newest advancements in high-efficiency HVAC systems.

Picture this: heat pumps that revolutionize energy efficiency, like a cool breeze on a scorching summer day.

In this article, we will delve into the world of heat pump technology, uncovering the key factors that contribute to their efficiency.

Stay tuned as we explore the cutting-edge innovations that make upgrading to a high-efficiency HVAC system a game-changer for your home.

Get ready to liberate your energy consumption!

Key Takeaways

- High-efficiency HVAC systems optimize energy usage and provide superior comfort.

- Regular maintenance, such as cleaning air filters and inspecting ductwork, ensures optimal performance.

- Upgrading to a high-efficiency HVAC system provides optimal comfort while reducing energy consumption and costs.

- The integration of advanced technologies in high-efficiency HVAC systems enhances overall performance and user experience.

Overview of High-Efficiency HVAC Systems

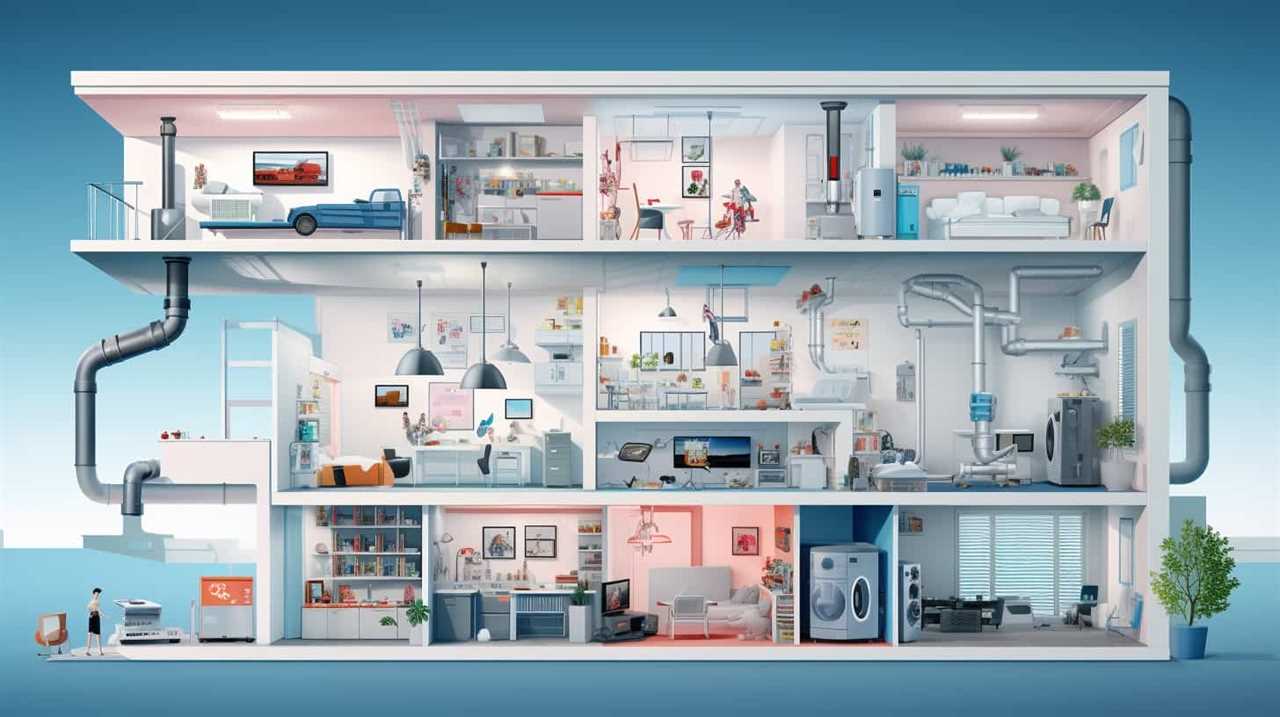

As we delve into the topic of high-efficiency HVAC systems, let’s start by providing an overview of these innovative heating, ventilation, and air conditioning systems.

High-efficiency HVAC systems are designed to optimize energy usage and provide superior comfort in residential and commercial spaces.

One key aspect of maintaining these systems is regular HVAC system maintenance. This includes cleaning or replacing air filters, checking and sealing ductwork, and inspecting and cleaning the outdoor unit.

By properly maintaining your HVAC system, you can ensure its optimal performance and longevity.

Additionally, implementing energy-saving tips can further enhance the efficiency of these systems. Simple steps such as adjusting the thermostat, sealing air leaks, and using ceiling fans can significantly reduce energy consumption and lower utility bills.

Understanding Heat Pump Technology

Let’s dive into the inner workings of heat pump technology and understand how it functions to efficiently heat and cool your space.

Heat pump operation relies on two essential heat transfer mechanisms:

-

Refrigerant: Heat pumps utilize a refrigerant, a substance that can change from a gas to a liquid and vice versa at low temperatures. This refrigerant is responsible for absorbing and releasing heat energy throughout the system.

-

Evaporation and Condensation: The refrigerant evaporates at a low temperature, absorbing heat from the surrounding air or ground. It then undergoes compression, raising its temperature and pressure. Next, it condenses, releasing the absorbed heat to the space being heated.

-

Reversing Valve: The heat pump can change the direction of refrigerant flow using a reversing valve, allowing it to switch between heating and cooling modes.

-

Compressor: The compressor is responsible for increasing the pressure and temperature of the refrigerant, ensuring efficient heat transfer.

-

Heat Exchanger: Heat pumps have two heat exchangers, one indoor and one outdoor. These devices facilitate the transfer of heat between the refrigerant and the air or ground.

Key Factors for Heat Pump Energy Efficiency

We can achieve optimal heat pump energy efficiency by considering key factors such as proper sizing, regular maintenance, and effective insulation.

Heat pump maintenance is crucial for ensuring its peak performance and longevity. Regularly cleaning or replacing air filters is a simple yet effective way to improve energy efficiency. Additionally, scheduling professional maintenance checks at least once a year can help identify and address any potential issues before they become major problems.

Another important factor is effective insulation. Properly insulating your home can prevent heat loss during winter and heat gain during summer, reducing the workload on your heat pump and saving energy.

Latest Innovations in High-Efficiency Heat Pumps

Our research has uncovered several exciting breakthroughs in high-efficiency heat pumps that are revolutionizing the HVAC industry. These innovations are driving energy efficiency and providing greater comfort and control for consumers.

Here are five key advancements in high-efficiency heat pumps:

-

Advancements in heat pump compressors: New compressor designs, such as variable speed and scroll compressors, are improving the overall efficiency of heat pumps by allowing them to adjust their output based on the heating and cooling demands.

-

Integration of smart technology: High-efficiency heat pumps now come equipped with smart features that enable users to control and monitor their HVAC systems remotely. This integration allows for optimized energy usage and personalized comfort settings.

-

Enhanced refrigerant technology: The development of new refrigerants with lower global warming potential (GWP) has significantly reduced the environmental impact of high-efficiency heat pumps.

-

Improved defrosting capabilities: Heat pumps now have advanced defrosting algorithms that optimize defrost cycles, reducing energy waste and improving system performance in cold climates.

-

Enhanced system diagnostics: High-efficiency heat pumps are equipped with advanced diagnostic tools that can detect and troubleshoot system issues, allowing for faster and more accurate repairs.

These innovations in high-efficiency heat pumps are making HVAC systems more efficient, reliable, and user-friendly, leading to energy savings and improved comfort for consumers.

Benefits of Upgrading to a High-Efficiency HVAC System

Upgrading to a high-efficiency HVAC system offers homeowners significant energy savings and improved indoor comfort. These systems are designed to operate more efficiently, resulting in lower energy consumption and reduced utility bills. By utilizing advanced technologies such as variable-speed motors and smart thermostats, high-efficiency HVAC systems can adapt to the specific needs of a home, providing precise temperature control and optimal energy usage. The environmental impact of upgrading to a high-efficiency system should also be considered. These systems consume less energy, which reduces greenhouse gas emissions and helps conserve natural resources. Additionally, some high-efficiency HVAC systems use eco-friendly refrigerants that have a lower impact on the ozone layer. Overall, upgrading to a high-efficiency HVAC system not only benefits homeowners financially but also contributes to a greener and more sustainable future.

| Benefits | Energy Savings | Environmental Impact |

|---|---|---|

| Lower utility bills | Reduced energy consumption | Reduced greenhouse gas emissions |

| Improved comfort | Precise temperature control | Conservation of natural resources |

| Advanced technologies | Optimal energy usage | Use of eco-friendly refrigerants |

Frequently Asked Questions

Are High-Efficiency HVAC Systems More Expensive to Install Than Traditional Systems?

High efficiency HVAC system installation costs can be higher than traditional systems initially, but in the long run, they can save money due to lower energy consumption. Additionally, high efficiency systems tend to have a longer lifespan.

Can a High-Efficiency Heat Pump Be Used in Both Heating and Cooling Modes?

Yes, a high-efficiency heat pump can be used in both heating and cooling modes. It offers energy efficiency benefits and reduces the environmental impact. This breakthrough technology is a game-changer for HVAC systems.

How Long Does It Typically Take for a High-Efficiency HVAC System to Pay for Itself Through Energy Savings?

Typically, the payback period for a high-efficiency HVAC system through energy savings varies. It depends on factors such as the initial cost, energy prices, and usage patterns. However, over time, these systems can help recoup their cost through lower energy bills.

Are There Any Government Incentives or Tax Credits Available for Upgrading to a High-Efficiency HVAC System?

Yes, there are government incentives and tax credits available for upgrading to a high-efficiency HVAC system. These incentives and credits can help offset the cost of installation and make the upgrade more affordable.

Can a High-Efficiency Heat Pump Be Used in Conjunction With a Traditional Furnace for Backup Heating During Extremely Cold Temperatures?

Yes, a high-efficiency heat pump can be used in conjunction with a traditional furnace for backup heating during extremely cold temperatures. This provides the advantages of geothermal heating and the reliability of a traditional furnace.

Conclusion

In conclusion, upgrading to a high-efficiency HVAC system with the latest innovations in heat pump technology can greatly improve energy efficiency and reduce utility costs. These breakthroughs in heat pump technology allow for better heat transfer and more precise temperature control, resulting in optimal comfort and savings.

So, why not take the leap and embrace the new era of high-efficiency HVAC systems? It’s time to reap the benefits and make your home a haven of efficiency and comfort. After all, ‘out with the old, in with the new’!

Refrigeration Cycle

3 Key Comparisons: Heat Pumps Vs Traditional Heating

Welcome, ladies and gentlemen, to our evaluation comparing heat pumps with traditional heating systems.

Today, we embark on a journey where facts will illuminate the path towards informed decision making. Join us as we delve into the realm of energy efficiency, cost effectiveness, and environmental impact.

With these key comparisons, we aim to shed light on the benefits and drawbacks of each option, empowering you to make a choice that aligns with your values and desires for a greener future.

Let’s begin.

Key Takeaways

- Heat pumps are more energy efficient than traditional heating systems.

- Heat pumps reduce carbon emissions and contribute to a greener future.

- Heat pumps provide efficient and effective heating and cooling solutions.

- Heat pumps can be powered by renewable energy sources.

Energy Efficiency Comparison

When comparing heat pumps to traditional heating systems, we find that heat pumps are more energy efficient. Heat pump technology utilizes the principles of refrigeration to transfer heat from one space to another.

Unlike traditional heating systems that generate heat by burning fuel, heat pumps extract heat from the air, ground, or water sources, making them more energy efficient. This energy efficiency leads to significant energy savings for homeowners and businesses.

Heat pumps can provide up to four times the amount of energy they consume, resulting in lower energy bills and reduced carbon emissions. By harnessing the natural heat available in the environment, heat pump technology offers a sustainable and cost-effective solution for heating and cooling needs.

Cost Comparison

In terms of cost, heat pumps offer a more budget-friendly option compared to traditional heating systems. One of the main advantages of heat pumps is their long-term savings potential. While the initial installation cost of a heat pump may be higher than that of a traditional heating system, the energy savings over time can offset this initial investment.

Heat pumps are highly energy efficient, as they transfer heat rather than generate it, resulting in lower energy consumption and reduced utility bills. Additionally, heat pumps require less maintenance compared to traditional heating systems, resulting in lower maintenance expenses over time. This further contributes to the cost-effectiveness of heat pumps.

Environmental Impact Comparison

Using heat pumps instead of traditional heating systems can significantly reduce our environmental impact while still providing efficient and effective heating.

The environmental benefits of heat pumps are evident when considering carbon footprint analysis and the integration of renewable energy.

-

Carbon footprint analysis:

-

Heat pumps utilize electricity to transfer heat, resulting in lower carbon emissions compared to fossil fuel-based heating systems.

-

Traditional heating systems, such as gas or oil furnaces, release greenhouse gases that contribute to climate change.

-

By choosing heat pumps, we can reduce our carbon footprint and help mitigate the effects of global warming.

-

Renewable energy integration:

-

Heat pumps can be powered by renewable energy sources like solar or wind power.

-

This integration promotes the use of clean and sustainable energy, reducing our reliance on fossil fuels.

-

By harnessing renewable energy for heat pumps, we can further minimize our environmental impact and contribute to a greener future.

Frequently Asked Questions

How Does the Installation Process of a Heat Pump Compare to That of a Traditional Heating System?

The installation process of a heat pump compared to that of a traditional heating system is more complex and requires professional expertise. However, once installed, heat pumps have lower maintenance requirements and provide greater energy efficiency.

Are There Any Specific Maintenance Requirements for Heat Pumps That Differ From Traditional Heating Systems?

When it comes to maintenance requirements, heat pumps differ from traditional heating systems. While the installation process may be similar, heat pumps require regular cleaning of filters and coils, as well as periodic inspections for optimal performance.

Can a Heat Pump Be Used in Conjunction With a Traditional Heating System to Maximize Efficiency?

Yes, a heat pump can be used in conjunction with a traditional heating system to maximize efficiency. By utilizing the heat pump’s efficiency and the traditional system’s capabilities, we can achieve optimal heating performance.

What Are the Noise Levels Typically Associated With Heat Pumps Compared to Traditional Heating Systems?

What are the noise levels typically associated with heat pumps compared to traditional heating systems? Are heat pumps quieter? Noise levels vary, but heat pumps generally operate at lower decibel levels, making them a quieter option for energy-efficient heating.

Are There Any Government Incentives or Tax Credits Available for Installing a Heat Pump Versus a Traditional Heating System?

There are government incentives and tax credits available for installing a heat pump compared to a traditional heating system. These incentives can help offset the cost and make it more affordable for homeowners.

Conclusion

Overall, when comparing heat pumps to traditional heating methods, it’s clear that heat pumps offer significant advantages.

With their higher energy efficiency, cost-effectiveness, and minimal environmental impact, heat pumps paint a picture of a greener and more sustainable future.

By harnessing the power of technology, we can transition away from outdated and inefficient heating systems, symbolizing a shift towards a cleaner and more efficient way of living.

Refrigeration Cycle

Boosting ROI: Energy-Efficient Heat Pumps Expense Analysis

Ladies and gentlemen, get ready as we explore the realm of energy-saving heat pumps and how they affect return on investment (ROI).

In this article, we’ll explore the factors that affect the cost-benefit analysis of heat pump efficiency and analyze the initial expenses involved.

But wait, there’s more! We’ll also calculate the long-term savings these pumps offer and reveal how to maximize ROI through upgrades.

Get ready to revolutionize your energy usage and boost your bottom line!

Key Takeaways

- ROI is crucial in determining the value of energy-efficient heat pumps.

- Factors such as energy prices and environmental impact should be considered in the cost-benefit analysis.

- Upfront expenses, maintenance costs, and incentives should be factored in when analyzing the initial expenses.

- Energy-efficient heat pumps can lead to long-term savings through reduced energy consumption and lower utility bills.

The Importance of ROI in Energy-Efficient Heat Pumps

We believe that ROI plays a crucial role in determining the value of energy-efficient heat pumps. For businesses and homeowners alike, it’s essential to consider the financial return on investment when deciding to adopt these innovative solutions.

The importance of ROI becomes even more evident when considering the impact on the environment. Energy-efficient heat pumps not only reduce energy consumption and utility costs but also significantly lower carbon footprint.

This is where government incentives come into play. By providing financial support and incentives for the adoption of energy-efficient heat pumps, governments can encourage individuals and organizations to invest in these environmentally friendly technologies. This not only benefits the environment but also helps businesses and homeowners save money in the long run.

Therefore, understanding the importance of ROI in energy-efficient heat pumps is crucial for making informed decisions and driving innovation in sustainable energy solutions.

Factors Affecting the Cost-Benefit Analysis of Heat Pump Efficiency

When evaluating the cost-benefit analysis of heat pump efficiency, it’s important to consider various factors that can impact the overall financial return on investment. Two key factors that must be taken into account are energy prices and the environmental impact of the heat pump system.

Energy prices play a significant role in determining the cost savings associated with heat pump efficiency. Higher energy prices can result in greater cost savings over time, as the energy-efficient heat pump consumes less electricity compared to traditional heating and cooling systems. On the other hand, lower energy prices may reduce the financial benefits of investing in a heat pump.

Furthermore, the environmental impact of the heat pump system is another important consideration. Heat pumps are known for their lower carbon emissions compared to conventional heating and cooling systems. By reducing reliance on fossil fuels, heat pumps contribute to a greener and more sustainable future. This environmental benefit must be factored into the cost-benefit analysis, as it adds value to the overall return on investment.

Analyzing the Initial Expenses of Energy-Efficient Heat Pumps

To accurately assess the financial viability of energy-efficient heat pumps, it’s essential to analyze the initial expenses involved and their impact on the return on investment. When conducting a cost analysis of energy-efficient heat pumps, the following factors should be considered:

-

Initial Investment: The upfront cost of purchasing and installing an energy-efficient heat pump is a significant expense. It includes the cost of the unit itself, any necessary modifications to the existing HVAC system, and professional installation fees.

-

Energy Savings: Energy-efficient heat pumps consume less electricity compared to traditional heating systems. By quantifying the potential energy savings over the lifespan of the heat pump, the long-term financial benefits can be determined.

-

Maintenance and Repair Costs: It’s important to factor in the ongoing maintenance and repair costs associated with energy-efficient heat pumps. Regular maintenance and occasional repairs are necessary to ensure optimal performance and longevity.

-

Incentives and Rebates: Various government incentives and utility company rebates may be available to offset the initial investment. These incentives can significantly reduce the overall cost and improve the return on investment.

Calculating Long-Term Savings With Energy-Efficient Heat Pumps

Our analysis aims to determine the long-term savings achieved by utilizing energy-efficient heat pumps. When considering the cost of implementing energy-efficient heat pumps, it’s essential to assess the long-term benefits and energy savings that can be achieved.

Energy-efficient heat pumps have the potential to significantly reduce energy consumption and lower utility bills. By utilizing advanced technology and innovative designs, these heat pumps can provide efficient heating and cooling solutions while minimizing energy wastage.

The long-term benefits of energy-efficient heat pumps include reduced energy costs, improved energy efficiency, and decreased environmental impact. These factors contribute to substantial savings over time, making energy-efficient heat pumps a wise investment for both residential and commercial applications.

Maximizing ROI Through Energy-Efficient Heat Pump Upgrades

The key to maximizing our ROI through energy-efficient heat pump upgrades lies in carefully selecting the most cost-effective and technologically advanced options available. By improving efficiency and taking advantage of financial benefits, we can significantly increase our returns on investment.

Here are four strategies to consider when upgrading heat pumps:

-

Conduct a thorough energy audit: Before making any upgrades, assess the current energy usage and identify areas for improvement. This will help determine the most effective upgrades to maximize ROI.

-

Choose high-efficiency heat pumps: Look for heat pumps that have a high SEER (Seasonal Energy Efficiency Ratio) rating and HSPF (Heating Seasonal Performance Factor) rating. These ratings indicate the energy efficiency of the heat pump and can greatly impact energy savings.

-

Consider variable-speed technology: Heat pumps with variable-speed compressors adjust their output based on the heating or cooling needs, resulting in more efficient operation and reduced energy consumption.

-

Explore financing options: Research available incentives, rebates, and financing programs to offset the initial cost of the upgrades. This can help improve the ROI and make the investment more financially feasible.

Frequently Asked Questions

How Do Heat Pumps Compare to Other Heating and Cooling Systems in Terms of Energy Efficiency?

Heat pumps offer higher energy efficiency compared to other heating and cooling systems. A comparative analysis reveals their lower environmental impact. This innovation provides a technical and analytical solution for boosting ROI and reducing energy expenses.

What Are the Key Factors to Consider When Analyzing the Long-Term Savings of Energy-Efficient Heat Pumps?

When analyzing the long-term savings of energy-efficient heat pumps, key factors to consider include energy savings and maintenance costs. By examining these factors, we can determine the overall return on investment for this innovative technology.

Are There Any Government Incentives or Rebates Available for Installing Energy-Efficient Heat Pumps?

Yes, there are government incentives and rebates available for installing energy-efficient heat pumps. These incentives aim to promote energy savings and make the adoption of such technology more financially feasible for consumers.

How Does the Climate or Geographical Location Affect the Cost-Benefit Analysis of Heat Pump Efficiency?

The climate and geographical location have a significant impact on the cost-benefit analysis of heat pump efficiency. Understanding these factors is crucial when evaluating the potential ROI and determining the most suitable energy-efficient heat pump system.

What Are Some Common Upgrades or Improvements That Can Be Made to Existing Heat Pump Systems to Maximize Roi?

Improving performance and maximizing ROI for existing heat pump systems can be achieved through various retrofit options. Upgrades such as variable speed drives, enhanced controls, and improved insulation can significantly enhance efficiency and reduce operating costs.

Conclusion

In conclusion, by considering the importance of ROI in energy-efficient heat pumps and analyzing the initial expenses as well as long-term savings, it’s evident that maximizing ROI through upgrades is crucial.

Factors affecting the cost-benefit analysis of heat pump efficiency should be taken into account to make informed decisions.

By implementing energy-efficient heat pumps, individuals can enjoy the benefits of reduced energy consumption and increased cost savings.

-

Residential and Commercial Applications2 weeks ago

Residential and Commercial Applications2 weeks agoBest Amana Heat Pump Reviews

-

Thermal Energy Transfer2 weeks ago

Thermal Energy Transfer2 weeks agoBreakthroughs in Modern Heat Pump Systems: Thermal Energy Edition

-

Residential and Commercial Applications2 weeks ago

Residential and Commercial Applications2 weeks agoBest Heat Pump

-

Geothermal Heat Pumps3 months ago

Geothermal Heat Pumps3 months agoUpgrade Your Comfort with Our Efficient HVAC Systems

-

Air Conditioning3 months ago

Air Conditioning3 months agoExploring Energy-Efficient Air Conditioning Heat Pumps

-

Geothermal Heat Pumps3 months ago

Geothermal Heat Pumps3 months agoInnovative Geothermal Heat Pump Manufacturers Revolutionize Energy Efficiency

-

Thermal Energy Transfer1 month ago

Thermal Energy Transfer1 month agoBoost Your Heat Pump Efficiency: Interactive Guide

-

Residential and Commercial Applications2 weeks ago

Residential and Commercial Applications2 weeks agoBest Portable Heat Pump Heat & AC