Refrigeration Cycle

Comparing Heat Pump and Traditional Heating: Energy Use

We have gathered data on energy usage and are prepared to make comparisons.

With heat pump systems, we’re looking at an average energy use of 3,500 kilowatt-hours per year.

But how does that stack up against traditional heating systems?

Buckle up, because we’re about to dive into the efficiency, environmental impact, and cost analysis of heat pumps versus traditional heating.

Prepare to find out which option gives you more bang for your buck while keeping the planet happy.

Key Takeaways

- Heat pumps are more energy-efficient than traditional heating systems, resulting in up to 50% energy savings and lower utility bills.

- Heat pumps have a lower carbon footprint and contribute to a greener and more sustainable future by reducing reliance on fossil fuels.

- Heat pumps are versatile, providing both heating and cooling functions, and can be used in various settings.

- While heat pumps may have higher upfront costs, they can be more cost-effective in the long run due to their energy efficiency, potential energy savings, and lower maintenance requirements.

Energy Consumption of Heat Pump Systems

We should compare the energy consumption of heat pump systems to traditional heating methods. When it comes to energy savings, heat pumps have a clear advantage. Heat pumps operate by transferring heat from one place to another, rather than generating heat directly. This makes them more energy-efficient, as they require less energy to produce the same amount of heat.

In fact, heat pumps can achieve energy savings of up to 50% compared to traditional heating systems. Not only do heat pumps offer significant energy savings, but they also have lower operating costs. Due to their high efficiency, heat pumps require less energy input, resulting in reduced utility bills.

Energy Consumption of Traditional Heating Systems

Our analysis will compare the energy consumption of traditional heating systems and highlight their differences when compared to heat pump systems.

Traditional heating systems, such as furnaces and boilers, rely on the combustion of fossil fuels or electricity to generate heat. These systems typically have lower upfront costs but can be less energy-efficient compared to heat pump systems. The energy saving features of traditional heating systems are limited, as they operate by converting fuel or electricity directly into heat without utilizing renewable energy sources.

Additionally, traditional heating systems often require regular maintenance to ensure optimal performance and prevent breakdowns. This includes cleaning or replacing filters, inspecting and repairing ductwork, and servicing the equipment.

Efficiency Comparison: Heat Pump Vs. Traditional Heating

The efficiency of heat pump systems can be compared to traditional heating systems to determine which option is more energy-efficient. When it comes to cost savings, heat pumps have a clear advantage. According to studies, heat pump systems can save homeowners up to 50% on their energy bills compared to traditional heating systems.

This is because heat pumps transfer heat from the outdoor air or ground to heat the indoor space, rather than generating heat through the combustion of fuel. Additionally, heat pumps have a lower carbon footprint compared to traditional heating systems. They produce fewer greenhouse gas emissions, helping to reduce environmental impact.

With their superior energy efficiency and reduced carbon emissions, heat pumps are a more sustainable and economical choice for heating homes.

Now, let’s delve into the environmental impact of heat pump systems compared to traditional heating methods.

Environmental Impact: Heat Pump Vs. Traditional Heating

When it comes to environmental impact, heat pump systems offer a more sustainable choice compared to traditional heating methods. Here are three reasons why:

-

Reduced Carbon Footprint: Heat pumps use electricity to transfer heat from the air or ground, resulting in significantly lower carbon emissions compared to burning fossil fuels in traditional heating systems. This reduction in greenhouse gas emissions helps mitigate climate change and lowers your overall environmental impact.

-

Utilization of Renewable Energy Sources: Heat pumps can be powered by renewable energy sources such as solar or wind power. By tapping into these clean energy sources, heat pumps further reduce dependence on fossil fuels and contribute to a greener and more sustainable future.

-

Efficient Energy Use: Heat pumps are highly efficient systems that can produce more heat energy than the electrical energy they consume. This means they can provide heating at a lower energy cost and with less waste compared to traditional heating methods.

Considering the environmental benefits and energy efficiency, heat pumps are a superior choice for those seeking a sustainable heating solution.

Now, let’s delve into the cost analysis of heat pump vs. traditional heating.

Cost Analysis: Heat Pump Vs. Traditional Heating

For a comprehensive understanding of the financial implications, let’s examine the cost analysis of using a heat pump versus traditional heating methods.

When considering the cost savings associated with heat pumps, it’s important to take into account the initial installation cost, as well as the long-term operational expenses. Heat pumps typically have higher upfront costs compared to traditional heating systems. However, the payback period for heat pumps is usually shorter due to their higher energy efficiency. This means that the cost savings from lower energy consumption can offset the initial investment within a shorter time frame.

Additionally, heat pumps offer the flexibility of dual functionality, providing both heating and cooling capabilities, further enhancing their cost-effectiveness.

Frequently Asked Questions

Are Heat Pumps Suitable for All Types of Homes and Buildings?

Heat pumps are suitable for most homes and buildings due to their versatility and energy efficiency. Installation costs vary depending on the size and type of home, but long-term savings from improved efficiency make them a worthwhile investment.

How Do Heat Pumps Affect Indoor Air Quality?

Heat pumps can have a positive impact on indoor air quality by reducing pollution from burning fossil fuels. Their efficiency in heating and cooling helps maintain a comfortable and healthy environment while minimizing the environmental footprint.

Do Heat Pumps Require Regular Maintenance?

Regular maintenance is crucial for heat pumps. It ensures optimal performance, extends their lifespan, and prevents costly repairs. Neglecting maintenance can lead to decreased efficiency and increased energy consumption. Don’t overlook the benefits of regular heat pump maintenance.

Can Heat Pumps Be Used for Both Heating and Cooling?

Yes, heat pumps can be used for both heating and cooling. They provide efficient heating by transferring heat from the outside air to the inside, and can also reverse the process to cool the indoor air. Heat pump installation costs vary depending on factors such as size and type.

What Are the Key Factors to Consider When Choosing Between a Heat Pump and Traditional Heating System?

When considering a heat pump vs. traditional heating system, we must analyze factors such as efficiency and cost effectiveness. By evaluating these key aspects, we can make an informed decision that aligns with our energy needs.

Conclusion

In conclusion, after analyzing the data and comparing the energy consumption, efficiency, environmental impact, and cost of heat pump systems and traditional heating systems, it’s evident that heat pumps are a more sustainable and cost-effective option.

The numbers speak for themselves, as heat pumps consistently outperform traditional heating methods.

It’s clear that when it comes to heating our homes, we should ‘kill two birds with one stone’ by choosing heat pumps that provide both energy savings and environmental benefits.

Refrigeration Cycle

Understanding the Importance of Heat Pump Maintenance

We have all experienced the frustration of a malfunctioning heat pump on a chilly winter day. It can leave us feeling like we are literally out in the cold. This is why it is crucial to understand the importance of regular maintenance for your heat pump.

Regular upkeep ensures optimal performance and extends the lifespan of your heat pump. From cleaning filters to troubleshooting issues, we’ll guide you through the ins and outs of maintaining this vital home appliance.

Don’t let your comfort be compromised – let’s dive into the world of heat pump maintenance together.

Key Takeaways

- Regular maintenance is crucial for optimal performance and extended lifespan of heat pumps.

- Professional maintenance services are recommended for thorough inspection and servicing.

- Regular maintenance helps ensure optimal energy efficiency and reduces energy consumption.

- Scheduling regular maintenance prevents minor issues from becoming major problems and saves on costly repairs.

The Basics of Heat Pump Maintenance

Now let’s talk about the basics of heat pump maintenance.

Regular maintenance is of utmost importance when it comes to ensuring the optimal performance and longevity of your heat pump system. By regularly maintaining your heat pump, you can prevent potential breakdowns, reduce energy consumption, and save on costly repairs in the long run.

While there are some maintenance tasks that you can perform yourself, such as cleaning or replacing air filters, it’s highly recommended to seek professional maintenance services. Professional technicians have the expertise and knowledge to thoroughly inspect and service your heat pump, identifying any underlying issues and addressing them promptly.

The benefits of professional maintenance services include improved energy efficiency, extended equipment lifespan, enhanced indoor air quality, and peace of mind knowing that your heat pump is operating at its best.

Why Regular Maintenance Is Essential for Heat Pumps

Regular maintenance is essential for heat pumps for two main reasons:

-

Prolonging the lifespan of the equipment and ensuring optimal energy efficiency. By scheduling regular maintenance, we can identify and address any potential issues before they become major problems, ultimately extending the life of the heat pump.

-

Regular maintenance helps to keep the heat pump running at peak performance, maximizing energy efficiency and reducing energy consumption.

Prolonging Heat Pump Lifespan

To ensure optimal performance and extend the lifespan of our heat pumps, it is crucial that we regularly maintain them. By conducting regular maintenance, we can reap numerous benefits such as reducing energy consumption, improving indoor air quality, and preventing costly repairs. Let’s take a look at the specific ways in which regular maintenance can help in extending the lifespan of our heat pumps:

| Maintenance Task | Benefits |

|---|---|

| Cleaning the filters | Improves airflow |

| Inspecting the coils | Enhances heat transfer |

| Checking refrigerant | Maintains efficiency |

Cleaning the filters regularly ensures that dust and debris do not accumulate, enabling proper airflow and preventing strain on the system. Inspecting the coils helps to remove any dirt or debris, which can hinder heat transfer and decrease efficiency. Lastly, checking the refrigerant levels ensures that the system is operating at its optimal level.

Ensuring Optimal Energy Efficiency

We can maximize energy efficiency by regularly maintaining our heat pumps and ensuring that they operate at their optimal level. Regular maintenance of heat pumps is essential for reducing energy consumption and maximizing efficiency.

When heat pumps aren’t properly maintained, they can become less efficient and consume more energy than necessary. This can lead to higher energy bills and a negative impact on the environment.

By scheduling regular maintenance, such as cleaning or replacing air filters, checking refrigerant levels, and inspecting electrical connections, we can ensure that our heat pumps are operating at their peak efficiency.

Additionally, regular maintenance allows for the early detection and repair of any potential issues, preventing them from developing into major problems that could lead to decreased energy efficiency.

Taking the time to maintain our heat pumps not only saves us money but also helps to reduce our overall energy consumption.

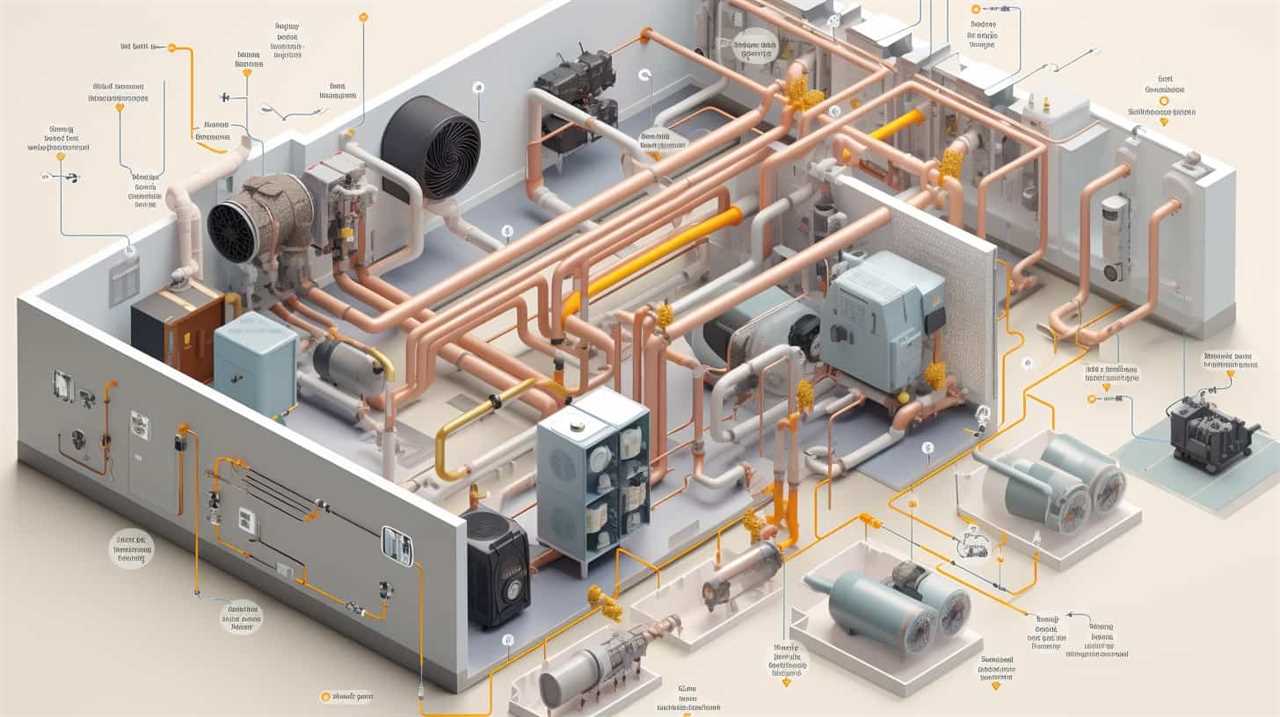

Understanding the Refrigeration Cycle in Heat Pumps

Let’s delve into the refrigeration cycle in heat pumps to gain a clearer understanding of its inner workings. Understanding the refrigeration cycle is crucial for effective heat pump troubleshooting and maintenance.

Here are the four main components of the refrigeration cycle:

-

Evaporator: This component absorbs heat from the surrounding air or water and converts it into a gaseous state.

-

Compressor: The compressor then increases the pressure and temperature of the refrigerant gas, making it ready for the next stage.

-

Condenser: The hot refrigerant gas flows into the condenser, where it releases heat to the outside environment and condenses back into a liquid state.

-

Expansion Valve: The expansion valve regulates the flow of the refrigerant into the evaporator, allowing it to expand and absorb heat again.

Understanding these refrigeration cycle components will help you identify potential issues and ensure the smooth operation of your heat pump.

Signs That Your Heat Pump Needs Maintenance

If we notice a decrease in heating or cooling efficiency, it may be a sign that our heat pump needs maintenance. Regular maintenance benefits our heat pump by ensuring it operates at peak performance and extends its lifespan.

Signs of wear and tear can manifest in various ways. One common sign is a decrease in the temperature differential between the supply and return air. This indicates that the heat pump is struggling to transfer heat effectively.

Another sign is an increase in noise levels, which could indicate issues with the fan or compressor. Additionally, if we notice a sudden increase in energy consumption, it could be a sign that our heat pump is working harder than necessary due to underlying issues.

Regular maintenance can help identify and address these signs before they escalate into larger and costlier problems.

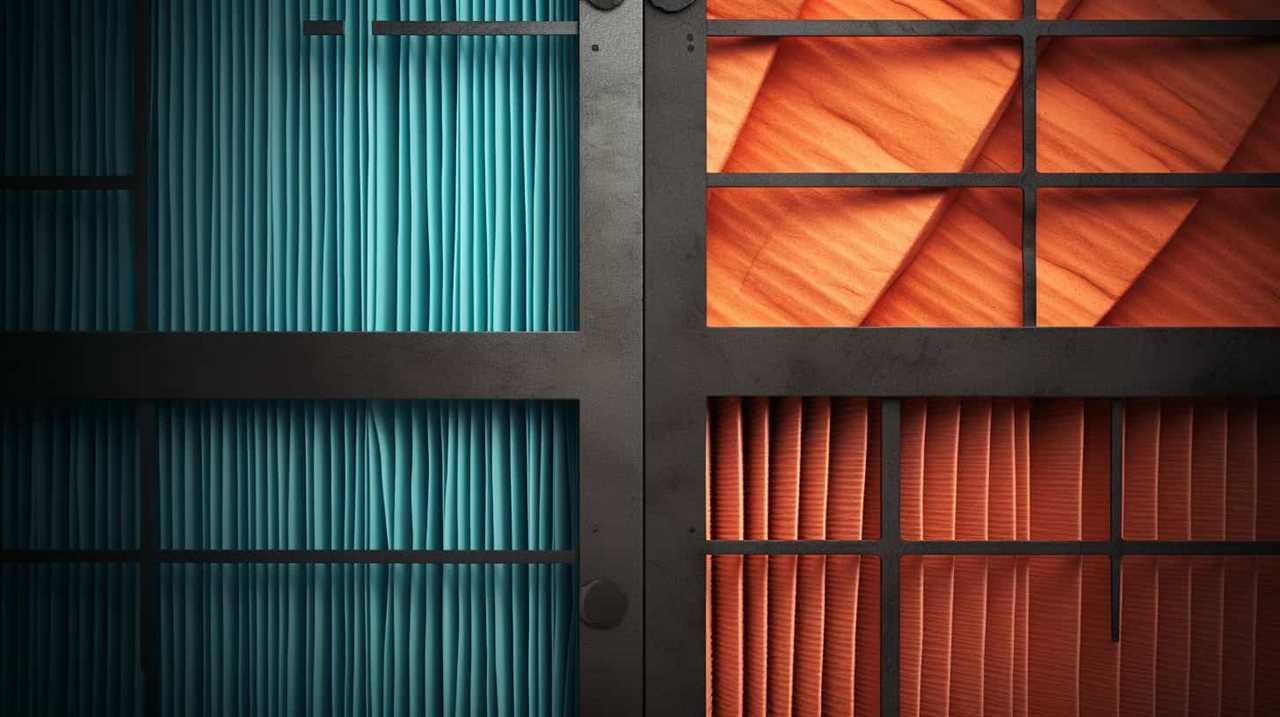

The Importance of Cleaning and Changing Filters

Regularly cleaning and changing filters is essential for maintaining the efficiency and performance of our heat pump. Here are four reasons why this task is of utmost importance:

-

Improved Air Quality: Clean filters prevent dust, dirt, and allergens from circulating in our indoor air, ensuring a healthier living environment for us and our loved ones.

-

Energy Efficiency: When filters are clogged with debris, the heat pump has to work harder to push air through, resulting in increased energy consumption and higher utility bills. Regularly cleaning or replacing filters helps maintain optimal airflow and energy efficiency.

-

Extended Lifespan: A clean filter reduces strain on the heat pump’s components, allowing it to operate smoothly. By regularly cleaning or replacing filters, we can extend the lifespan of our heat pump and avoid costly repairs or premature replacements.

-

Maximized Performance: High-quality filters are designed to effectively trap particles while allowing sufficient airflow. By using high-quality filters, we can ensure that our heat pump operates at its maximum performance, providing us with consistent heating and cooling.

Regularly cleaning and changing filters is a simple yet crucial maintenance task that contributes to the overall efficiency, longevity, and performance of our heat pump.

Tips for Proper Lubrication and Belt Maintenance

For optimal performance and longevity of our heat pump, we should prioritize proper lubrication and belt maintenance. Regular lubrication of the heat pump’s moving parts is essential to reduce friction and prevent wear and tear. It is important to use the correct lubrication technique for each component, as specified by the manufacturer. The table below provides a quick reference guide for the lubrication techniques of common heat pump components:

| Component | Lubrication Technique |

|---|---|

| Fan motor bearings | Apply lubricating oil |

| Blower motor bearings | Apply lubricating oil |

| Compressor | Use compressor oil |

| Drive shaft | Apply high-temperature grease |

| Pulleys and belts | Use belt dressing |

In addition to lubrication, proper belt tensioning is crucial for efficient heat pump operation. Incorrect belt tension can lead to slippage, reduced performance, and premature belt failure. Belt tension should be checked regularly and adjusted using the appropriate belt tensioning methods recommended by the manufacturer. By following these maintenance tips, we can ensure that our heat pump operates at its best. Now, let’s move on to discussing common issues with the heat pump refrigeration cycle.

SUBSEQUENT SECTION: ‘Common Issues with Heat Pump Refrigeration Cycle’

Common Issues With Heat Pump Refrigeration Cycle

Three common issues can arise with the heat pump refrigeration cycle, and addressing them promptly is essential for optimal performance and energy efficiency. Here are four common problems to be aware of:

-

Troubleshooting refrigerant leaks: Refrigerant leaks can occur due to corrosion, faulty connections, or punctures in the refrigerant lines. Detecting and repairing leaks is crucial as they can lead to reduced cooling or heating capacity and increased energy consumption.

-

Troubleshooting compressor issues: The compressor is a vital component of the heat pump refrigeration cycle. Issues such as motor failure, electrical problems, or refrigerant flooding can compromise its performance. Timely diagnosis and repair of compressor issues are crucial for maintaining efficient operation.

-

Inadequate refrigerant charge: An improper refrigerant charge can result in reduced efficiency and performance. It can be caused by leaks or improper installation. Regular inspections and maintenance can help identify and rectify this issue.

-

Reversing valve malfunctions: The reversing valve allows the heat pump to switch between heating and cooling modes. If it becomes stuck or fails to function correctly, the heat pump may not be able to provide the desired temperature control.

Understanding these common issues with the heat pump refrigeration cycle is important for ensuring optimal performance. In the next section, we’ll discuss how to troubleshoot and diagnose heat pump problems to address these issues effectively.

How to Troubleshoot and Diagnose Heat Pump Problems

Now let’s turn our attention to the common issues that can arise with heat pumps and how to troubleshoot them. By understanding these common problems and learning how to diagnose them, you can save time and money on costly repairs.

In this section, we’ll discuss the troubleshooting process for heat pumps, providing you with the knowledge and skills to effectively identify and resolve any issues that may arise.

Common Heat Pump Issues

We often encounter various issues with heat pumps, and it’s essential to troubleshoot and diagnose these problems accurately. Here are four common heat pump issues that homeowners may experience:

-

Refrigerant Leak: A refrigerant leak can lead to reduced cooling or heating capacity. Signs include hissing sounds, ice formation, or a drop in performance. A professional technician can locate and repair the leak while ensuring proper refrigerant levels.

-

Electrical Problems: Faulty wiring, blown fuses, or tripped breakers can cause the heat pump to malfunction. It’s important to check the electrical connections and circuit breakers for any issues. If necessary, a qualified electrician should be called to address these problems.

-

Frozen Coils: If the heat pump coils freeze, it can lead to poor performance or a complete system shutdown. This can be caused by issues such as airflow restrictions, dirty air filters, or low refrigerant levels. Regularly cleaning and maintaining the system can help prevent frozen coils.

-

Thermostat Malfunction: A malfunctioning thermostat can lead to inconsistent temperature control or the heat pump not turning on/off as desired. Checking the thermostat settings, replacing batteries if needed, or recalibrating the thermostat can help resolve these issues.

Troubleshooting Heat Pump

First, let’s discuss two common troubleshooting steps that can help diagnose heat pump problems. When troubleshooting a heat pump, it’s important to start with the basics.

Firstly, check the thermostat settings to ensure they’re correctly programmed. Incorrect settings can lead to the heat pump not working as desired.

Secondly, inspect the air filters to see if they’re dirty or clogged. Dirty filters can restrict airflow, causing the heat pump to work harder and less efficiently.

These two steps can often resolve common heat pump issues and prevent unnecessary repairs. However, if the problem persists, it’s recommended to contact a professional technician who can further diagnose and troubleshoot the heat pump system.

Scheduling Professional Maintenance for Optimal Performance

To ensure optimal performance, we recommend scheduling professional maintenance for your heat pump at least once a year. Regular maintenance is essential for preventing heat pump breakdowns and maximizing its lifespan.

Here are the benefits of professional maintenance:

-

Improved Efficiency: A well-maintained heat pump operates more efficiently, reducing energy consumption and lowering your utility bills.

-

Enhanced Comfort: Regular maintenance ensures that your heat pump is delivering the desired heating and cooling capacity, keeping you comfortable throughout the year.

-

Extended Lifespan: Professional maintenance helps identify and address minor issues before they escalate, prolonging the life of your heat pump and delaying the need for costly replacements.

-

Warranty Compliance: Many manufacturers require annual professional maintenance to maintain the warranty coverage for your heat pump. Regular servicing ensures that you’re in compliance with these requirements.

Frequently Asked Questions

How Often Should I Schedule Professional Maintenance for My Heat Pump?

We schedule professional maintenance for our heat pump regularly to ensure optimal performance. The frequency of scheduling depends on factors like usage, manufacturer recommendations, and climate conditions. DIY maintenance can supplement professional servicing.

Can I Perform Heat Pump Maintenance Myself, or Should I Always Hire a Professional?

We recommend hiring a professional for heat pump maintenance. While DIY heat pump maintenance may seem appealing, the benefits of hiring a professional include expertise, thorough inspections, and peace of mind.

Are There Any Specific Signs or Indicators That My Heat Pump Is in Need of Immediate Maintenance?

There are common signs that indicate the need for immediate heat pump maintenance. Regular maintenance is important to prevent breakdowns and ensure optimal performance.

What Are the Potential Consequences of Neglecting Regular Heat Pump Maintenance?

Neglecting heat pump maintenance can lead to potential consequences such as decreased energy efficiency, higher utility bills, reduced lifespan of the heat pump, and costly repairs. Regular maintenance is crucial to avoid these issues.

Are There Any Maintenance Tasks That I Can Do on a Monthly or Quarterly Basis to Ensure Optimal Heat Pump Performance?

Monthly tasks include cleaning or replacing air filters, checking and cleaning the outdoor unit, and inspecting the thermostat settings. Quarterly tasks involve cleaning the evaporator and condenser coils, lubricating fan motors, and inspecting electrical connections.

Conclusion

So there you have it, folks. Heat pump maintenance is absolutely crucial for optimal performance.

Who knew that such a complex system could require so much attention?

But hey, it’s all worth it in the end, right?

So go ahead, schedule that professional maintenance and enjoy the irony of spending time and money to keep your heat pump running smoothly. Trust me, you won’t regret it.

Refrigeration Cycle

Unveiling Secrets of Heat Pump Refrigeration Cycle

We are committed to solving the mysteries of the refrigeration cycle in heat pumps.

We’ll delve into the inner workings of this fascinating system, exploring its components and step-by-step process.

Our goal is to shed light on the heat transfer and compression that drive the cycle, while also explaining its efficiency.

Whether you’re a technician troubleshooting common issues or simply curious about how it all works, join us as we unveil the mysteries of the heat pump refrigeration cycle.

Key Takeaways

- The heat pump refrigeration cycle transfers heat from a low-temperature source to a high-temperature sink.

- Understanding the components and process of the cycle is essential for energy efficiency and maintenance.

- Maximizing efficiency of heat transfer is crucial and can be achieved through factors such as insulation, surface area, and fluid flow.

- Optimizing refrigerant flow, including proper selection and control, is important for system performance.

The Basics of a Heat Pump Refrigeration Cycle

In our discussion of the basics of a heat pump refrigeration cycle, let’s explore its fundamental components and operation.

A heat pump operates by transferring heat from a low-temperature source to a high-temperature sink, utilizing the properties of a refrigerant. The refrigerant plays a crucial role in this process, as it undergoes phase changes and absorbs or releases heat.

The properties of the refrigerant, such as its boiling point and specific heat capacity, dictate the efficiency and performance of the heat pump. By changing the pressure and temperature of the refrigerant, the heat pump can extract heat from the source and deliver it to the sink.

This cycle of compression, condensation, expansion, and evaporation allows the heat pump to provide heating or cooling for various applications. Understanding the operation and characteristics of the refrigerant is essential for optimizing the efficiency and effectiveness of heat pump systems.

Understanding the Components of a Heat Pump Refrigeration Cycle

Let’s take a closer look at the components of a heat pump refrigeration cycle to understand how they work together to transfer heat efficiently. The key components of a heat pump refrigeration cycle include the evaporator, compressor, condenser, and expansion valve.

The evaporator is responsible for absorbing heat from the indoor air and converting it into a gaseous refrigerant. The compressor then increases the pressure and temperature of the refrigerant, making it ready for the next stage.

Next, the refrigerant flows into the condenser, where it releases heat to the outdoor air, causing it to condense into a liquid state. Finally, the expansion valve reduces the pressure of the refrigerant, allowing it to return to the evaporator and continue the cycle.

Understanding these components is crucial for optimizing energy efficiency and ensuring proper heat pump maintenance. Regular maintenance, such as cleaning the coils and checking for refrigerant leaks, can help maintain the performance and efficiency of the heat pump.

Step-by-Step Process of a Heat Pump Refrigeration Cycle

As we delve into the step-by-step process of a heat pump refrigeration cycle, we can gain a deeper understanding of how heat is transferred efficiently.

Here are the key steps involved in this process:

-

Evaporation: The refrigerant absorbs heat from the surrounding air or water, causing it to evaporate and turn into a gas.

-

Compression: The compressor increases the pressure of the refrigerant gas, which raises its temperature.

-

Condensation: The hot refrigerant gas is then passed through a condenser, where it releases heat to the surroundings and condenses back into a liquid.

To ensure the smooth functioning of a heat pump refrigeration cycle, it’s important to perform regular maintenance and employ troubleshooting techniques. Regularly cleaning or replacing filters, checking for leaks, and ensuring proper airflow are some maintenance tips that can help optimize the system’s performance.

Understanding the step-by-step process and implementing maintenance techniques will pave the way for effective heat transfer in a heat pump refrigeration cycle.

Heat Transfer in a Heat Pump Refrigeration Cycle

When it comes to heat transfer in a heat pump refrigeration cycle, the efficiency of the process is of utmost importance. Optimizing the flow of refrigerant plays a crucial role in ensuring efficient heat transfer.

Efficiency of Heat Transfer

Our goal is to maximize the efficiency of heat transfer in the heat pump refrigeration cycle. To achieve this, we can focus on heat transfer enhancement and thermal conductivity improvement. Here are three key factors to consider:

-

Insulation: By improving the insulation of the heat pump system, we can minimize heat loss and maintain a higher level of efficiency. This can be achieved through proper insulation materials and techniques.

-

Surface area: Increasing the surface area of the heat exchanger can enhance heat transfer. This can be done by using fins or other heat transfer enhancement techniques to maximize the contact between the refrigerant and the surrounding environment.

-

Fluid flow: Optimizing the flow of the refrigerant within the system can improve heat transfer efficiency. This can be achieved by designing the system to reduce pressure drops and ensure a uniform flow distribution.

By implementing these strategies, we can enhance the efficiency of heat transfer in the heat pump refrigeration cycle, leading to improved performance and energy savings.

Now, let’s move on to the next section about optimizing refrigerant flow.

Optimizing Refrigerant Flow

To optimize heat transfer in a heat pump refrigeration cycle, we focus on improving the flow of the refrigerant through the system. Proper refrigerant selection and flow control are crucial factors in achieving efficient and effective heat transfer.

The choice of refrigerant is important as it affects the overall performance of the heat pump system. Factors to consider when selecting a refrigerant include its thermodynamic properties, environmental impact, and safety regulations.

Optimal flow control is achieved through the use of expansion valves and variable speed compressors, which allow for precise regulation of the refrigerant flow rate. By ensuring that the refrigerant flows smoothly and consistently through the heat pump system, heat transfer efficiency is maximized, leading to improved performance and energy savings.

The Role of Compression in a Heat Pump Refrigeration Cycle

In the heat pump refrigeration cycle, compression plays a vital role in increasing the temperature and pressure of the refrigerant. This is achieved through the use of a compressor, which compresses the refrigerant gas and raises its temperature.

Here are three important points to understand about the role of compression in the heat pump refrigeration cycle:

-

Compressor Efficiency: The efficiency of the compressor is crucial in ensuring the proper functioning of the heat pump. A more efficient compressor will require less energy to achieve the desired temperature and pressure increase, resulting in lower energy consumption and cost.

-

Refrigerant Properties: The properties of the refrigerant, such as its specific heat capacity and boiling point, greatly influence the compression process. Understanding these properties helps in selecting the right refrigerant for optimal heat transfer and overall system efficiency.

-

Pressure-Volume Relationship: Compression causes the refrigerant to move from a low-pressure region to a high-pressure region, resulting in an increase in its temperature. This relationship between pressure and volume is fundamental to the operation of the heat pump refrigeration cycle.

Heat Pump Refrigeration Cycle Efficiency Explained

When discussing the efficiency of a heat pump refrigeration cycle, there are several key points to consider.

The first is the Coefficient of Performance (COP), which measures the ratio of heat output to the energy input. This is an important metric in determining the overall efficiency of the heat pump.

Additionally, energy-saving technology plays a crucial role in maximizing efficiency, such as variable-speed compressors and smart control systems.

Lastly, understanding the heat transfer mechanisms involved in the cycle, including conduction, convection, and radiation, helps optimize the system for optimal efficiency.

Coefficient of Performance

We can measure the efficiency of the heat pump refrigeration cycle by calculating its coefficient of performance. This metric allows us to determine how effectively the heat pump is transferring heat from one location to another.

Here are three key aspects to consider when discussing the coefficient of performance:

-

Energy Efficiency: The coefficient of performance indicates the ratio of heat output to the amount of electrical energy input required by the heat pump. A higher coefficient of performance means the heat pump is more energy-efficient, resulting in lower energy consumption and cost savings.

-

Heat Pump Maintenance: Regular maintenance is crucial to ensure the heat pump operates at its optimal performance. Factors such as proper refrigerant levels, clean filters, and well-functioning components can positively impact the coefficient of performance.

-

System Design: The coefficient of performance can also be influenced by the design of the heat pump system. Proper sizing, insulation, and ductwork play a significant role in maximizing efficiency.

Understanding the coefficient of performance helps us identify areas for improvement and optimize the heat pump’s energy efficiency.

Now, let’s delve into the next section, which explores energy-saving technology.

Energy-Saving Technology

Our article will now delve into the energy-saving technology that enhances the efficiency of the heat pump refrigeration cycle. Energy-efficient solutions play a vital role in reducing the environmental impact of HVAC systems. By incorporating advanced technology and innovative design, heat pump refrigeration cycles can achieve higher levels of efficiency, resulting in significant energy savings.

One such energy-saving technology is variable-speed compressors. These compressors can adjust their speed based on the cooling or heating demands of the space, ensuring that the system operates at optimal efficiency without unnecessary energy consumption. Additionally, the use of intelligent controls and sensors helps optimize the system’s performance by monitoring and adjusting various parameters in real-time.

Heat Transfer Mechanisms

To enhance the efficiency of the heat pump refrigeration cycle, we employ various heat transfer mechanisms that enable optimal heat transfer between the refrigerant and the surrounding environment. These heat transfer mechanisms play a crucial role in maintaining the desired temperature and maximizing energy savings.

-

Convection: By utilizing convection, heat is transferred through the movement of fluid or air. As the refrigerant absorbs heat from the surroundings, it becomes hotter and rises, allowing cooler air or fluid to take its place and continue the heat transfer process.

-

Conduction: Conduction involves the direct transfer of heat through a solid material. The refrigerant, as it flows through the heat exchanger, comes into contact with the solid walls, transferring heat through the process of conduction.

-

Radiation: Radiation is the transfer of heat through electromagnetic waves. In the heat pump refrigeration cycle, radiation occurs when heat is emitted or absorbed by the refrigerant and surrounding environment.

Troubleshooting Common Issues in a Heat Pump Refrigeration Cycle

Identifying and addressing common issues is essential for maintaining the efficiency of a heat pump refrigeration cycle. Troubleshooting techniques can help diagnose and resolve these issues, ensuring that the heat pump operates optimally.

One common maintenance issue is inadequate airflow, which can be caused by dirty air filters or obstructed vents. To address this, regularly clean or replace air filters and ensure that vents are clear of any debris.

Another issue is refrigerant leaks, which can result in reduced cooling or heating capacity. Detecting and repairing these leaks is crucial for restoring the system’s performance.

Additionally, electrical problems such as faulty wiring or malfunctioning components can disrupt the heat pump’s operation. Regular inspections and maintenance checks can help identify and resolve these issues promptly, ensuring the smooth functioning of the heat pump refrigeration cycle.

Frequently Asked Questions

What Are the Different Types of Refrigerants Used in a Heat Pump Refrigeration Cycle?

There are various refrigerant types used in a heat pump refrigeration cycle. These include R-410A, R-134a, and R-32. Each has its advantages and suitability for specific applications. Heat pumps offer efficient heating and cooling solutions for homes.

How Does the Size of a Heat Pump Affect Its Efficiency?

The size of a heat pump is crucial to its efficiency. A larger heat pump can provide more heating or cooling power, but it may also consume more energy, leading to higher heating and cooling costs.

Can a Heat Pump Refrigeration Cycle Be Used for Cooling Purposes Only?

Yes, a heat pump refrigeration cycle can be used for cooling purposes only. However, it is important to consider heat pump efficiency and perform regular heat pump maintenance to ensure optimal performance and energy savings.

Are There Any Environmental Concerns Associated With the Use of Heat Pump Refrigeration Cycles?

There are some environmental concerns associated with heat pump refrigeration cycles. These include the potential for refrigerant leaks, which can contribute to climate change, and the use of electricity, which may not always be generated from renewable sources. However, heat pump refrigeration cycles are generally more energy efficient than other cooling systems, which can help reduce overall environmental impact.

What Are the Main Factors That Can Affect the Lifespan of a Heat Pump Refrigeration Cycle?

Factors affecting the lifespan of a heat pump refrigeration cycle include regular maintenance requirements, such as cleaning the filters and coils, as well as proper installation and sizing of the system.

Conclusion

In conclusion, understanding the heat pump refrigeration cycle is crucial for efficient cooling and heating systems.

One interesting statistic that may surprise you is that heat pump refrigeration cycles can achieve an impressive efficiency of up to 300-400%, meaning they produce more energy than they consume.

This remarkable efficiency not only saves energy but also reduces carbon emissions, making heat pump refrigeration cycles a sustainable and environmentally friendly choice.

Refrigeration Cycle

Understand the Intricacies of Heat Pump Refrigeration Cycle

Are you ready to delve into the fascinating world of heat pump refrigeration cycles?

Strap in, because we’re about to take you on a journey through the intricate workings of these systems.

Just like a well-oiled machine, we’ll guide you through the evaporation process, the role of the compressor, and the condensation process.

We’ll also explore heat transfer and insulation, troubleshoot common issues, and show you how to maximize energy efficiency.

Get ready to become a heat pump expert!

Key Takeaways

- Heat pump technology offers advantages over traditional heating and cooling systems, and understanding its operation is essential to grasp the refrigeration cycle.

- The choice of refrigerants significantly affects the performance and efficiency of heat pump systems, and using environmentally friendly refrigerants is important for sustainability.

- The evaporation process and the role of the compressor are crucial in the refrigeration cycle, as they affect heat transfer and energy efficiency.

- Factors such as the choice of refrigerant, design of heat exchangers, and proper insulation levels and installation all play a role in maximizing heat transfer efficiency and reducing energy losses.

The Basics of Heat Pump Operation

We need to understand the basics of how a heat pump operates in order to grasp the intricacies of its refrigeration cycle.

Heat pump technology offers several advantages over traditional heating and cooling systems, making it an attractive option for many homeowners.

The installation of a heat pump involves a few key steps. First, the outdoor unit is positioned in a suitable location outside the home. Then, refrigerant lines are connected to the indoor unit, which is usually installed in a utility room or basement. The indoor unit is responsible for distributing heated or cooled air throughout the home.

By utilizing the principles of refrigeration, a heat pump can efficiently transfer heat from one area to another, providing both warmth in the winter and coolness in the summer.

Understanding the basics of heat pump operation is essential as we delve further into the role of refrigerants in heat pump systems.

Understanding the Role of Refrigerants in Heat Pump Systems

Refrigerants play a crucial role in the operation of heat pump systems, impacting both their efficiency and environmental impact. It’s important to consider the specific properties of the refrigerants used, such as their thermodynamic characteristics and global warming potential, when designing and operating heat pump systems.

Environmental considerations, such as the phase-out of certain refrigerants due to their ozone depletion potential, also need to be taken into account in order to ensure the sustainability of heat pump technology.

Impact of Refrigerants

As we delve into the intricacies of the heat pump refrigeration cycle, it becomes evident that the choice of refrigerants plays a crucial role in the overall performance and efficiency of the system. The impact of refrigerants can be significant, both in terms of environmental impact and system efficiency. Here are three key points to consider:

-

Refrigerant types: There are various types of refrigerants available, each with its own unique properties and environmental impact. Common refrigerant types include hydrofluorocarbons (HFCs), hydrochlorofluorocarbons (HCFCs), and natural refrigerants such as ammonia and carbon dioxide. Choosing the right refrigerant involves considering factors such as efficiency, safety, and environmental regulations.

-

Environmental regulations: With increasing concerns about climate change and ozone depletion, there are stringent regulations in place to control the use of refrigerants. Many countries have phased out or are in the process of phasing out high-global warming potential (GWP) refrigerants in favor of lower-GWP alternatives. It’s important to stay updated with these regulations to ensure compliance and minimize environmental impact.

-

System efficiency: The choice of refrigerant can greatly impact the efficiency of a heat pump system. Refrigerants with higher heat transfer coefficients and lower pressure drops can enhance the overall performance of the system. Additionally, factors such as refrigerant charge, system design, and maintenance practices can also influence system efficiency.

Understanding the impact of refrigerants is crucial for optimizing the performance and efficiency of heat pump systems while complying with environmental regulations. By making informed choices and adopting best practices, we can serve our audience by providing sustainable and efficient heating and cooling solutions.

Environmental Considerations

For optimal environmental considerations, it’s important to understand the role of refrigerants in heat pump systems and the impact they have on sustainability and efficiency.

Refrigerants play a crucial role in the heat pump cycle as they facilitate the transfer of heat from one location to another. However, certain refrigerants have been found to have detrimental effects on the environment, such as contributing to global warming and depleting the ozone layer.

To address these concerns, there has been a shift towards using refrigerants that have a lower global warming potential and zero ozone depletion potential. This shift towards more environmentally friendly refrigerants not only helps in reducing emissions but also promotes sustainable practices.

The Evaporation Process in a Heat Pump Refrigeration Cycle

We actively participate in the evaporation process within a heat pump refrigeration cycle. Evaporation is a crucial step in the cycle, where the refrigerant, in a low-pressure state, absorbs heat from the surrounding environment and undergoes a phase change from a liquid to a vapor.

This process occurs in the evaporator coil, where the refrigerant enters as a low-temperature liquid and exits as a low-temperature vapor. The evaporation efficiency is determined by factors such as the temperature difference between the refrigerant and the surrounding environment, the surface area of the evaporator coil, and the evaporation rate.

It’s important to optimize the evaporation process to maximize the heat transfer and improve the overall efficiency of the heat pump system. As we move on to discuss the role of the compressor in heat pump operation, it’s essential to understand the significance of the evaporation process in the refrigeration cycle.

The Role of the Compressor in Heat Pump Operation

The compressor plays a crucial role in the operation of a heat pump. Its main function is to compress the refrigerant, raising its temperature and pressure. This is essential for the refrigerant to release heat during the condensation process.

The efficiency of the compressor is of utmost importance, as it directly affects the overall performance and energy consumption of the heat pump system.

Regular maintenance and proper care of the compressor are necessary to ensure its optimal functioning and longevity.

Compressor’s Function and Design

To fully grasp the inner workings of a heat pump, it’s essential to understand the role and design of the compressor, which plays a crucial part in the operation of the system. The compressor is responsible for pressurizing the refrigerant, increasing its temperature and pressure to facilitate heat transfer.

Here are three key aspects to consider when discussing the function and design of the compressor:

-

Compressor Efficiency: The efficiency of the compressor is vital for the overall performance of the heat pump. Higher efficiency means lower energy consumption and reduced operating costs. Regular maintenance, such as cleaning or replacing air filters, lubricating moving parts, and checking refrigerant levels, can help optimize the compressor’s efficiency.

-

Compressor Maintenance: Proper maintenance is essential to ensure the compressor’s longevity and reliability. Regular inspections, cleaning, and servicing can help identify and address potential issues before they escalate. This includes checking for leaks, monitoring refrigerant levels, and ensuring proper airflow.

-

Compressor Design: Compressor design varies depending on the specific heat pump system. Factors such as size, capacity, and type of refrigerant impact the design choices. It’s crucial to select a compressor that matches the system requirements to ensure optimal performance and efficiency.

Understanding the function and design of the compressor is crucial for maintaining the efficiency and performance of a heat pump system. Regular maintenance and selecting the right compressor design can contribute to a reliable and energy-efficient operation.

Importance of Compressor Efficiency

Maintaining high compressor efficiency is crucial for optimizing the performance of a heat pump system. The compressor plays a vital role in the heat pump operation by compressing the refrigerant gas, raising its temperature and pressure, and facilitating heat transfer.

However, over time, the compressor may experience wear and tear, which can lead to reduced efficiency and performance. Regular compressor maintenance is essential to prevent these issues and ensure optimal operation.

Energy-saving techniques, such as keeping the compressor clean and free from debris, ensuring proper lubrication, and monitoring refrigerant levels, can help improve compressor efficiency. Additionally, regular inspections, timely repairs, and replacing worn-out parts can also contribute to maintaining high compressor efficiency.

Compressor Maintenance Tips

Our top compressor maintenance tip is regularly cleaning and inspecting the compressor to ensure optimal heat pump operation. Here are three key compressor maintenance techniques that can help troubleshoot compressor issues:

-

Check for refrigerant leaks: Inspect the compressor for any signs of refrigerant leakage such as oil stains or hissing sounds. Leaks can lead to reduced cooling capacity and inefficient operation.

-

Clean the condenser coil: Dust and debris can accumulate on the condenser coil, reducing heat transfer and causing the compressor to work harder. Regularly clean the coil using a soft brush or compressed air to maintain efficient heat exchange.

-

Lubricate moving parts: The compressor contains various moving parts that require lubrication to reduce friction and prevent wear. Check the manufacturer’s guidelines for the recommended lubrication schedule and use the appropriate lubricant.

By following these compressor maintenance techniques, you can ensure the longevity and efficiency of your heat pump system.

Now, let’s move on to discussing the condensation process in a heat pump refrigeration cycle.

The Condensation Process in a Heat Pump Refrigeration Cycle

During the condensation process in a heat pump refrigeration cycle, we extract heat from the refrigerant gas as it transitions to a liquid state. This is a crucial step in the refrigeration cycle as it allows the heat pump to transfer heat from a lower temperature source to a higher temperature sink. To better understand the condensation process, let’s take a look at the following table:

| Stage | Description | Purpose |

|---|---|---|

| 1 | High-pressure, high-temperature refrigerant gas enters the condenser. | To release heat and cool the gas. |

| 2 | The refrigerant gas cools and condenses into a high-pressure liquid. | To remove heat from the gas and prepare it for the expansion process. |

| 3 | Heat is transferred to the surroundings as the refrigerant releases heat energy. | To maintain a temperature difference between the refrigerant and the surroundings. |

| 4 | The refrigerant exits the condenser as a high-pressure liquid. | To continue to the next stage of the refrigeration cycle. |

Exploring the Expansion Valve in Heat Pump Systems

Let’s explore how the expansion valve works in heat pump systems. The expansion valve is a critical component in the refrigeration cycle that controls the flow of refrigerant. Its primary function is to reduce the pressure of the refrigerant as it enters the evaporator.

Here are three key points to understand about the expansion valve:

-

Expansion Valve Function: The expansion valve acts as a metering device that regulates the flow of refrigerant from the high-pressure side to the low-pressure side of the system. It ensures that the refrigerant enters the evaporator at the right pressure and temperature for efficient heat transfer.

-

Expansion Valve Efficiency: The efficiency of the expansion valve is crucial for optimal system performance. It must be able to accurately control the flow of refrigerant and maintain the desired pressure drop across the valve. This helps to maximize the heat transfer capacity of the evaporator and improve overall system efficiency.

-

Importance of Proper Sizing: The expansion valve needs to be properly sized for the specific heat pump system. If the valve is too small, it can restrict the flow of refrigerant and cause inefficiencies. On the other hand, if the valve is too large, it can lead to poor temperature control and reduced system performance.

Understanding the function and efficiency of the expansion valve is essential for ensuring the proper operation of a heat pump system. Now, let’s transition into the subsequent section about heat transfer in a heat pump refrigeration cycle.

Heat Transfer in a Heat Pump Refrigeration Cycle

Heat transfer occurs within a heat pump refrigeration cycle as the refrigerant absorbs and releases heat during its journey through the system. The efficiency of heat transfer is a crucial consideration in heat pump design.

To achieve optimal heat transfer efficiency, several factors must be taken into account. One such factor is the choice of refrigerant, as different refrigerants have varying heat transfer properties.

Additionally, the design of heat exchangers plays a vital role in facilitating efficient heat transfer. Proper sizing and placement of heat exchangers ensure maximum contact between the refrigerant and the medium being heated or cooled.

Furthermore, the flow rate of the refrigerant must be carefully controlled to maintain efficient heat transfer. By addressing these heat pump design considerations, we can enhance the heat transfer efficiency of the system.

This leads us to the next topic: the importance of proper insulation in heat pump efficiency.

The Importance of Proper Insulation in Heat Pump Efficiency

Proper insulation plays a crucial role in maximizing heat pump efficiency. By minimizing heat transfer, insulation helps to reduce energy losses and improve overall system performance.

Ensuring optimal insulation levels is essential for achieving energy savings and maintaining the desired temperature in a heat pump system.

Insulation and Energy Savings

Our insulation plays a crucial role in maximizing our heat pump’s efficiency and energy savings. Proper insulation is essential for maintaining optimal temperature levels inside our homes, reducing heat loss or gain, and ultimately saving energy. Here are three key factors to consider when it comes to insulation and energy savings:

-

Insulation Benefits:

Insulation acts as a barrier, preventing the transfer of heat between the inside and outside of our homes. By reducing heat loss during colder months and heat gain during warmer months, insulation helps to maintain a comfortable indoor environment without over-reliance on our heat pump system. This leads to significant energy savings and lower utility bills. -

Insulation Types:

There are various insulation types available, including fiberglass, cellulose, spray foam, and rigid foam. Each type has its own thermal resistance properties, installation requirements, and cost considerations. Choosing the right insulation type for our specific needs is crucial to ensure maximum energy efficiency. -

Proper Installation:

Proper installation of insulation is critical for its effectiveness. Gaps, leaks, or inadequate coverage can compromise the insulation’s performance and lead to energy loss. It’s essential to hire a professional to ensure proper installation, as they’ve the knowledge and expertise to achieve optimal results.

Impact on Heat Transfer

With the right insulation, we can significantly improve the efficiency of our heat pump by minimizing heat transfer. Heat transfer is the movement of thermal energy from one object to another, and in the case of a heat pump, it can have a significant impact on its performance.

Proper insulation helps to prevent heat loss or gain during the refrigeration cycle, ensuring that the heat pump operates at its optimal efficiency. Insulation acts as a barrier, reducing the transfer of heat between the indoor and outdoor environments. This means that less energy is required to heat or cool the space, resulting in improved heat pump efficiency and performance.

By investing in high-quality insulation materials and ensuring proper installation, we can maximize the benefits of our heat pump and achieve greater energy savings.

In the next section, we’ll explore additional factors that are crucial in ensuring optimal performance of our heat pump.

Ensuring Optimal Performance

To achieve optimal performance, we must ensure that proper insulation is in place and that heat transfer is minimized in our heat pump refrigeration cycle. Improving performance and optimizing efficiency are crucial in order to provide the best service to our customers.

Here are three key factors to consider when it comes to insulation:

-

Insulation material: Choosing the right insulation material is essential for reducing heat transfer. Materials such as fiberglass, foam board, and cellulose insulation offer excellent thermal resistance, helping to maintain the desired temperature inside the system.

-

Insulation thickness: The thickness of the insulation also plays a significant role in minimizing heat transfer. Thicker insulation provides better resistance to heat flow, resulting in improved energy efficiency.

-

Proper installation: Ensuring proper installation of the insulation is vital to avoid any gaps or air leaks. Any gaps can lead to heat loss or gain, which negatively impacts the overall efficiency of the heat pump system.

By implementing these insulation measures, we can enhance the performance and efficiency of our heat pump refrigeration cycle.

Now, let’s delve into troubleshooting common issues in heat pump refrigeration cycles.

Troubleshooting Common Issues in Heat Pump Refrigeration Cycles

We can identify and resolve common issues in heat pump refrigeration cycles by following a systematic troubleshooting process. When troubleshooting heat pump refrigeration cycles, it’s essential to have a good understanding of the system’s components and how they interact with each other.

Some common malfunctions in heat pump refrigeration cycles include inadequate heating or cooling, low airflow, refrigerant leaks, and electrical problems. To diagnose these issues, it’s important to use troubleshooting techniques such as checking for error codes, inspecting electrical connections, measuring temperatures and pressures, and examining airflow.

Once the problem is identified, it can be resolved by repairing or replacing faulty components, recharging refrigerant if needed, or adjusting settings. By effectively troubleshooting these common issues, we can ensure that heat pump refrigeration cycles operate optimally and efficiently.

Transitioning into the subsequent section about maximizing energy efficiency in heat pump operation, let’s explore some strategies to minimize energy consumption while maintaining comfort.

Maximizing Energy Efficiency in Heat Pump Operation

To optimize energy efficiency in heat pump operation, we can implement various strategies that enhance the system’s performance and minimize energy consumption.

Here are three effective ways to maximize energy savings and improve heat pump performance:

-

Regular maintenance: Conducting routine maintenance is crucial for ensuring the optimal functioning of a heat pump. This includes cleaning or replacing filters, inspecting coils and connections, and lubricating moving parts. Regular maintenance helps to prevent energy waste and extends the lifespan of the heat pump.

-

Proper insulation: Ensuring that your home is well-insulated can significantly reduce heat loss and gain, allowing the heat pump to operate more efficiently. Insulating walls, ceilings, and floors, as well as sealing air leaks, helps to maintain a consistent indoor temperature and reduces the workload on the heat pump.

-

Thermostat management: Adjusting the thermostat settings can have a significant impact on energy consumption. Lowering the temperature in winter and raising it in summer by a few degrees can lead to substantial energy savings. Additionally, using programmable thermostats allows for customized temperature schedules, optimizing comfort and efficiency.

Frequently Asked Questions

Can a Heat Pump Be Used to Cool a Space as Well as Heat It?

Yes, a heat pump can be used to cool a space in addition to heating it. This is achieved by reversing the refrigeration cycle. The efficiency and lifespan of a heat pump depend on regular maintenance and proper installation.

How Does the Efficiency of a Heat Pump Compare to Other HVAC Systems?

The efficiency of a heat pump compared to other HVAC systems is remarkable. It allows for significant energy savings, making it an excellent choice for both heating and cooling.

What Is the Average Lifespan of a Heat Pump?

The average lifespan of a heat pump varies depending on factors such as maintenance requirements. Regular maintenance can help extend the lifespan of a heat pump, ensuring optimal performance and efficiency.

Are There Any Government Incentives or Rebates Available for Purchasing a Heat Pump?

Yes, there are government incentives and rebates available for purchasing a heat pump. These programs can help offset the cost and make it more affordable for homeowners to invest in energy-efficient heating and cooling solutions.

Can a Heat Pump Be Used in Extreme Climates With Very Cold Temperatures?

Yes, a heat pump can be used in extreme climates with very cold temperatures. However, it’s important to consider heat pump sizing and regular heat pump maintenance to ensure optimal performance in these conditions.

Conclusion

In conclusion, understanding the intricacies of the heat pump refrigeration cycle is crucial for efficient operation.

By comprehending the role of refrigerants, the processes of evaporation and condensation, and the importance of heat transfer and insulation, users can maximize energy efficiency.

For example, proper insulation can significantly reduce heat loss and improve overall performance.

By troubleshooting common issues and implementing energy-saving techniques, heat pump systems can provide reliable heating and cooling while minimizing energy consumption.

-

Residential and Commercial Applications5 months ago

Residential and Commercial Applications5 months agoBest Amana Heat Pump Reviews

-

Thermal Energy Transfer5 months ago

Thermal Energy Transfer5 months agoBreakthroughs in Modern Heat Pump Systems: Thermal Energy Edition

-

Residential and Commercial Applications5 months ago

Residential and Commercial Applications5 months agoBest Heat Pump

-

Geothermal Heat Pumps4 months ago

Geothermal Heat Pumps4 months agoUpgrade Your Comfort with Our Efficient HVAC Systems

-

Geothermal Heat Pumps4 months ago

Geothermal Heat Pumps4 months agoInnovative Geothermal Heat Pump Manufacturers Revolutionize Energy Efficiency

-

Air Conditioning3 months ago

Air Conditioning3 months agoExploring Energy-Efficient Air Conditioning Heat Pumps

-

Thermal Energy Transfer2 months ago

Thermal Energy Transfer2 months agoBoost Your Heat Pump Efficiency: Interactive Guide

-

Air Conditioning5 months ago

Air Conditioning5 months agoHeat Pumps Outperform Traditional Heating in Energy Use