Installation and Maintenance of Heat Pumps

Unveiling Heat Pump Refrigeration Cycle’s Latest Tech Updates

We’re excited to showcase the newest developments in heat pump refrigeration cycle technology. Get ready to be astonished by the latest enhancements in compressors, condensers, evaporators, expansion valves, defrosting methods, control systems, and heat recovery.

Our precise and detailed article will take you on a technical journey, painting a picture of the future outlook for heat pump refrigeration.

Join us as we serve you with the most up-to-date information in this ever-evolving field.

Key Takeaways

- Heat pump compressor technology has advanced with the introduction of variable speed compressors and scroll compressors, resulting in higher efficiency and reduced operational costs.

- Heat pump condenser design has been enhanced with features such as enhanced heat transfer surfaces, microchannel technology, corrosion-resistant materials, and variable speed fans, leading to better control, improved energy efficiency, and easier installation.

- Heat pump evaporator technology has seen innovations in heat transfer efficiency, energy consumption reduction, compact coil designs, advanced materials, and optimized refrigerant flow for uniform heat transfer, resulting in improved performance.

- Heat pump expansion valve design has been upgraded with features like variable orifice size, enhanced energy efficiency, intricate construction, and improved refrigerant flow regulation, contributing to overall system efficiency and performance.

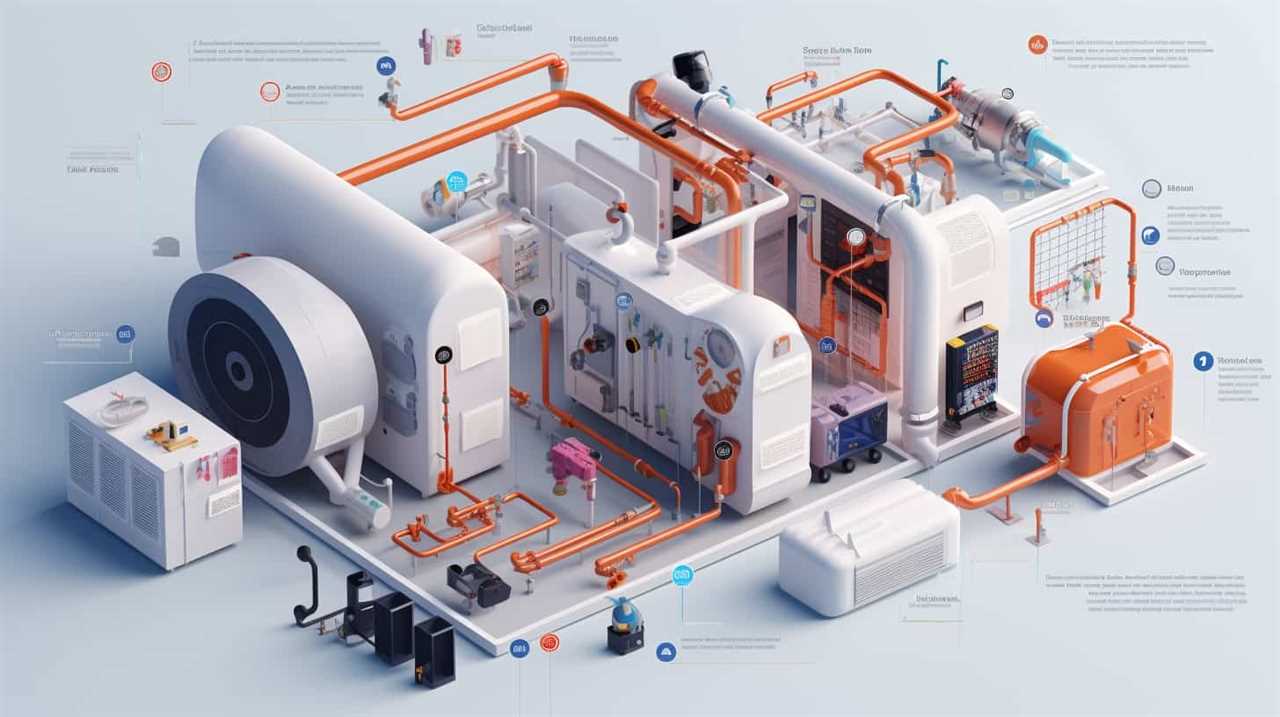

Overview of Heat Pump Refrigeration Cycle

What are the key components and functions of the heat pump refrigeration cycle?

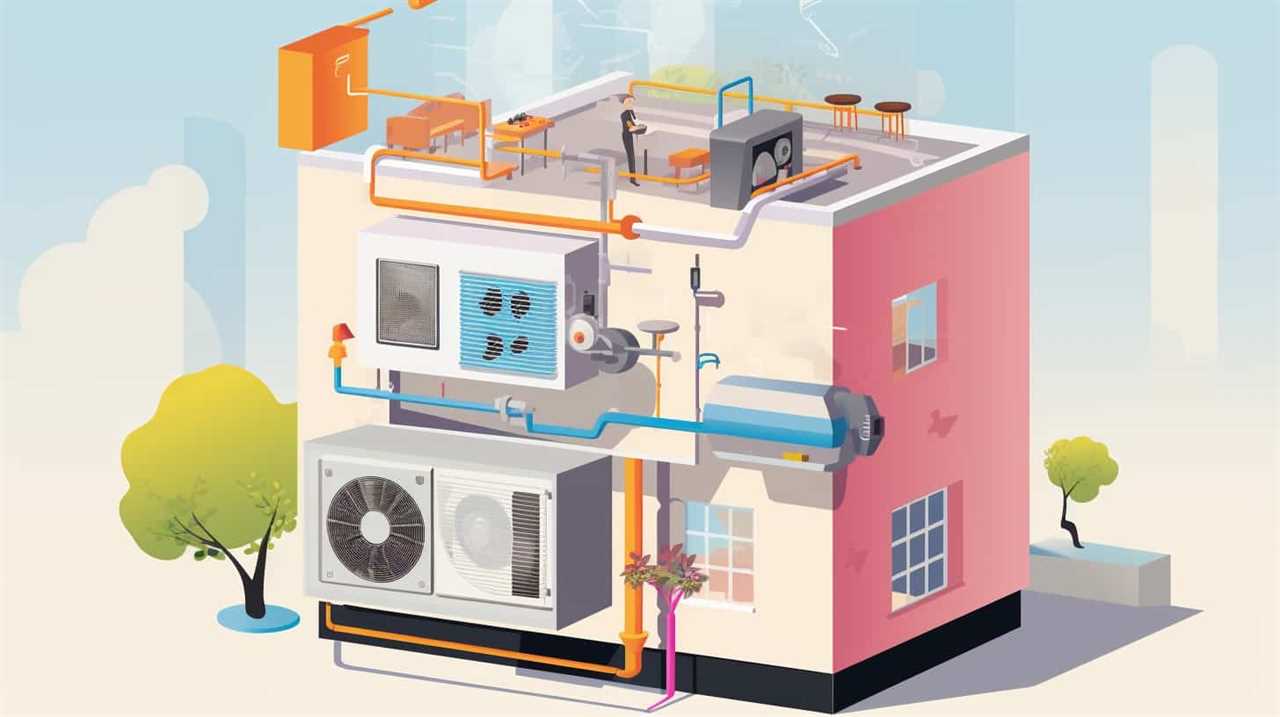

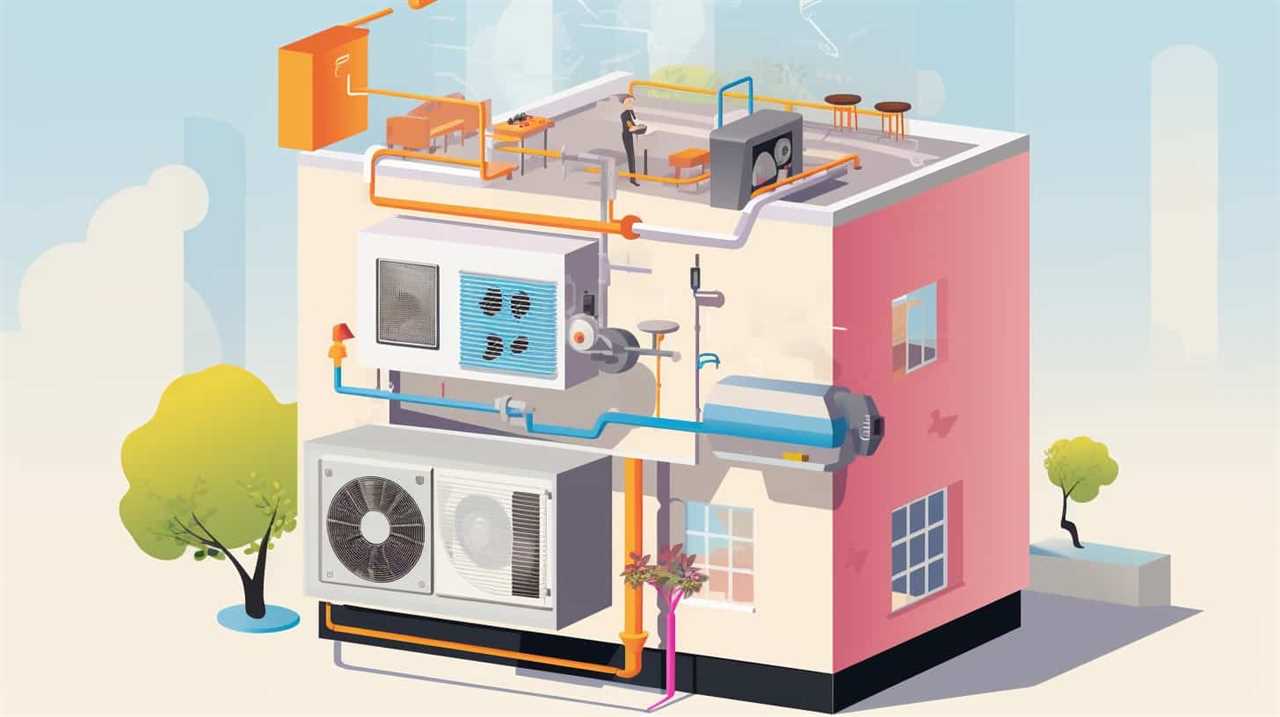

The heat pump refrigeration cycle consists of four main components: the compressor, condenser, expansion valve, and evaporator.

The cycle begins with the compressor, which increases the pressure and temperature of the refrigerant.

The high-pressure, high-temperature refrigerant then flows into the condenser, where it releases heat to the surroundings and condenses into a liquid.

The liquid refrigerant passes through the expansion valve, which reduces its pressure and temperature.

This low-pressure, low-temperature refrigerant then enters the evaporator, where it absorbs heat from the surrounding environment and evaporates into a gas.

The advantages of the heat pump refrigeration cycle include its ability to provide both heating and cooling, making it suitable for a wide range of applications such as residential and commercial buildings, as well as industrial processes.

Advancements in Heat Pump Compressor Technology

We have discovered exciting advancements in heat pump compressor technology. These advancements have brought significant benefits to the field of heat pump refrigeration cycles.

One major advancement is the development of variable speed compressors. These compressors can adjust their speed based on the cooling or heating demands, resulting in improved energy efficiency and reduced energy consumption.

Another advancement is the use of scroll compressors, which have a higher efficiency compared to traditional piston compressors. Scroll compressors also have fewer moving parts, reducing the risk of mechanical failure and increasing the overall lifespan of the compressor.

Additionally, advancements in compressor materials have led to improved durability and reliability, allowing for longer maintenance intervals and reduced operational costs.

These advancements in heat pump compressor technology are revolutionizing the industry, providing more efficient and reliable heating and cooling solutions.

Enhancements in Heat Pump Condenser Design

The latest advancements in heat pump condenser design have resulted in improved efficiency and performance. These enhancements have focused on the use of advanced heat pump condenser materials and condenser heat transfer techniques.

Here are some key features of the latest heat pump condenser designs:

Enhanced heat transfer surfaces: The condenser surfaces have been optimized to maximize heat transfer, allowing for improved heat exchange between the refrigerant and the surrounding air.

Microchannel technology: This design utilizes small channels to increase the surface area available for heat transfer, resulting in higher efficiency and reduced refrigerant charge.

Corrosion-resistant materials: The use of corrosion-resistant materials in condenser construction ensures long-lasting performance and minimizes maintenance requirements.

Variable speed fans: These fans can adjust their speed based on the heat load, providing better control and improved energy efficiency.

Compact design: The latest heat pump condensers are designed to be more compact, allowing for easier installation and reducing space requirements.

With these advancements in heat pump condenser design, we can now transition into discussing the innovations in heat pump evaporator technology.

Innovations in Heat Pump Evaporator Technology

As we delve into the topic of innovations in heat pump evaporator technology, it’s important to understand the latest advancements in this crucial component of the refrigeration cycle. Heat pump evaporator design plays a significant role in the overall performance and efficiency of a heat pump system. Recent developments in evaporator technology have focused on improving heat transfer efficiency and reducing energy consumption.

One key area of innovation is the enhancement of heat pump evaporator design to increase the surface area available for heat exchange. This can be achieved through the use of compact, high-performance coil designs or the incorporation of advanced materials with improved thermal conductivity. By maximizing the heat transfer surface area, evaporators can effectively extract heat from the surrounding environment and transfer it to the refrigerant.

Another focus of innovation is on evaporator performance improvements. Efforts have been made to optimize the refrigerant flow and distribution within the evaporator, ensuring uniform heat transfer across the entire surface. This helps to minimize temperature differences and improve overall system efficiency. Additionally, advancements in control systems and sensors allow for better monitoring and adjustment of evaporator performance, ensuring optimal operation under varying load conditions.

Upgrades in Heat Pump Expansion Valve Design

We will now discuss the upgrades in heat pump expansion valve design.

These upgrades aim to improve the efficiency of the heat pump system through expansion, enhance control over the refrigerant flow, and optimize overall performance.

Improved Efficiency Through Expansion

Our research has identified three key upgrades in heat pump expansion valve design that have significantly improved efficiency. These upgrades focus on expansion efficiency and performance optimization.

Variable orifice design: The new expansion valves feature a variable orifice design, allowing for precise control of refrigerant flow based on system requirements. This improves overall system efficiency by reducing unnecessary refrigerant flow and minimizing energy consumption.

Improved sensing technology: The latest expansion valves incorporate advanced sensing technology, enabling them to accurately measure system conditions and adjust the refrigerant flow accordingly. This ensures optimal performance and efficiency under varying operating conditions.

Enhanced flow control: The upgraded expansion valves have enhanced flow control mechanisms, such as stepper motor actuators, which provide precise and immediate response to system demands. This results in improved system stability and efficiency.

Integrated temperature and pressure regulation: The new expansion valves integrate temperature and pressure regulation functions, allowing for better control and optimization of the refrigerant flow. This ensures optimal heat transfer and system efficiency.

Enhanced reliability and durability: The latest expansion valves are designed with high-quality materials and improved construction techniques, ensuring long-term reliability and durability. This reduces maintenance requirements and enhances the overall performance of the heat pump system.

Enhanced Control and Performance

Two significant upgrades in heat pump expansion valve design have been implemented to enhance control and performance.

The first upgrade focuses on improved temperature regulation. By incorporating advanced temperature sensors and control algorithms, the heat pump system can accurately monitor and adjust the flow of refrigerant through the expansion valve. This ensures that the desired temperature is maintained consistently, resulting in increased comfort and energy efficiency.

The second upgrade involves advanced system monitoring. With the integration of smart technology and data analytics, the heat pump system can continuously monitor various parameters such as pressure, temperature, and flow rate. This real-time monitoring allows for proactive detection of any potential issues or inefficiencies, enabling timely maintenance and optimization of the system’s performance.

These advancements in heat pump expansion valve design significantly contribute to enhanced control and performance, providing users with a more efficient and reliable heating and cooling solution.

Latest Trends in Heat Pump Refrigerant Selection

When considering the latest trends in heat pump refrigerant selection, three important points come to mind.

Firstly, the environmental impact of refrigerants is a crucial factor to consider, as certain refrigerants have a high global warming potential.

Secondly, energy efficiency improvements are a key consideration, as selecting a refrigerant with higher energy efficiency can lead to significant energy savings.

Lastly, emerging refrigerant technologies are being developed, such as low GWP (global warming potential) refrigerants and natural refrigerants, which offer promising alternatives to traditional refrigerants.

Environmental Impact of Refrigerants

What are the latest trends in heat pump refrigerant selection and their environmental impact?

Environmental regulations are pushing for the phase-out of refrigerants with high global warming potential (GWP).

Alternative refrigerants with lower GWP are being developed and adopted by manufacturers.

Natural refrigerants like hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs) are being replaced by options like hydrofluoroolefins (HFOs) and hydrofluorocarbons (HFCs).

Low-GWP blends, such as HFO-1234ze and HFO-1234yf, are gaining popularity due to their reduced environmental impact.

Some heat pump systems are even exploring the use of carbon dioxide (CO2) as a refrigerant, which has a GWP of 1 and is considered environmentally friendly.

These trends in heat pump refrigerant selection reflect the industry’s commitment to reducing the environmental impact of refrigerants while still providing efficient and reliable cooling solutions. By embracing alternative refrigerants and complying with environmental regulations, manufacturers can contribute to a sustainable future.

Energy Efficiency Improvements

As we delve into the topic of energy efficiency improvements, let’s explore the latest trends in heat pump refrigerant selection.

In recent years, there’s been a growing emphasis on energy saving techniques and sustainable cooling solutions. One of the key trends in heat pump refrigerant selection is the shift towards low global warming potential (GWP) refrigerants. These refrigerants have a significantly lower environmental impact compared to traditional high GWP refrigerants, contributing to the overall sustainability of heat pump systems.

Additionally, there’s been a focus on selecting refrigerants with high thermodynamic efficiency, which helps to improve the overall energy efficiency of heat pump systems.

Emerging Refrigerant Technologies

Let’s explore the latest trends in heat pump refrigerant selection and uncover the emerging technologies in the field. As emerging refrigerant regulations continue to tighten, the focus is shifting towards selecting refrigerants with lower global warming potential (GWP) and higher energy efficiency.

Here are the top five emerging refrigerant technologies:

Hydrofluoroolefins (HFOs): These next-generation refrigerants have significantly lower GWP compared to traditional refrigerants.

Natural refrigerants: Substances like ammonia, carbon dioxide, and hydrocarbons have gained popularity due to their low environmental impact.

Blends: Refrigerant blends, such as HFC/HFO blends, provide a balance between performance and environmental impact.

Zeotropic refrigerants: These mixtures have different boiling points, allowing for better heat transfer and efficiency.

Azeotropic refrigerants: These refrigerants have a constant boiling point, ensuring stable performance throughout the cycle.

With emerging refrigerant technologies, we can reduce the impact on global warming while improving heat pump system efficiency.

Now, let’s dive into the next section about improvements in heat pump system efficiency.

Improvements in Heat Pump System Efficiency

We have achieved significant improvements in heat pump system efficiency through the implementation of advanced technologies. These advancements haven’t only increased the cost effectiveness of heat pump systems but also enhanced their durability.

One major improvement is the use of variable speed compressors, which allow the system to adjust its capacity based on the heating or cooling demands. This reduces energy consumption and improves overall efficiency.

Additionally, the integration of advanced controls and algorithms has optimized the system’s performance and minimized energy waste.

Furthermore, advancements in heat exchanger technology have led to increased heat transfer efficiency, resulting in improved system performance.

These improvements in efficiency have made heat pump systems more reliable and cost-effective, providing greater value to homeowners and businesses.

With these advancements, we can now transition into discussing breakthroughs in heat pump defrosting techniques.

Breakthroughs in Heat Pump Defrosting Techniques

We have made significant progress in improving heat pump defrosting techniques, resulting in enhanced defrosting efficiency and energy conservation.

Our latest breakthroughs have focused on developing advanced algorithms and sensors that accurately detect frost build-up and initiate the defrost cycle at the optimal time.

Additionally, we’ve integrated innovative heat transfer technologies that effectively remove frost from the heat exchanger surfaces, minimizing energy consumption and maximizing system performance.

Improved Defrosting Efficiency

With the latest breakthroughs in heat pump defrosting techniques, we can now achieve improved efficiency in the defrosting process. This is crucial for ensuring the seamless operation of heat pumps and maximizing their performance.

Here are some efficient defrosting techniques and defrosting cycle optimization methods that have emerged:

Hot gas defrosting: Utilizing the heat from the refrigerant to melt ice buildup on the heat exchanger coils.

Reverse cycle defrosting: Reversing the refrigerant flow to warm up the outdoor coil and remove frost accumulation.

Intelligent defrost control: Implementing advanced algorithms to optimize the timing and duration of defrost cycles based on real-time conditions.

Frost detection sensors: Installing sensors to detect frost buildup and trigger the defrosting process when necessary.

Enhanced coil design: Incorporating innovative coil designs that minimize frost formation and facilitate quicker defrosting.

By implementing these techniques, heat pump systems can effectively and efficiently manage defrosting, leading to improved performance and enhanced energy conservation.

Now, let’s delve into the next section to explore how these advancements contribute to enhanced energy conservation.

Enhanced Energy Conservation

Through advancements in heat pump defrosting techniques, we can now achieve enhanced energy conservation by optimizing the defrosting process. By implementing improved insulation techniques and smart thermostat integration, heat pumps can operate more efficiently and reduce energy consumption.

To illustrate the impact of these advancements, let’s consider the following table:

| Traditional Defrosting | Enhanced Defrosting | |

|---|---|---|

| Energy Consumption | High | Low |

| Efficiency | Low | High |

| Heating Capacity | Reduced | Maintained |

| Operating Costs | High | Low |

| Environmental Impact | High | Low |

As shown in the table, enhanced defrosting techniques result in lower energy consumption, increased efficiency, maintained heating capacity, reduced operating costs, and a lower environmental impact.

With these breakthroughs in energy conservation, we can now transition to discussing new developments in heat pump control systems.

New Developments in Heat Pump Control Systems

Our research has identified several significant advancements in heat pump control systems. These developments aim to improve the efficiency and performance of heat pumps by incorporating improved control algorithms and smart thermostat integration.

Here are some key updates in this field:

Enhanced control algorithms: New algorithms have been developed to optimize the operation of heat pumps, allowing for better regulation of temperature and energy consumption.

Smart thermostat integration: Heat pumps can now be integrated with smart thermostats, enabling users to remotely control and monitor their systems through mobile applications or voice commands.

Adaptive defrost technology: Heat pumps now employ adaptive defrost cycles, which intelligently regulate the defrosting process based on real-time weather conditions and system performance.

Fault detection and diagnostics: Advanced control systems can now detect and diagnose faults in heat pumps, allowing for timely maintenance and troubleshooting.

Energy management systems: Heat pump control systems can now be integrated with energy management systems, allowing users to optimize energy usage and reduce overall energy consumption.

These advancements in heat pump control systems not only enhance the performance and efficiency of heat pumps but also provide users with greater convenience and control over their heating and cooling systems.

Advances in Heat Pump Heat Recovery Technology

As we delve into the topic of advances in heat pump heat recovery technology, it is important to highlight the recent developments that have revolutionized the efficiency and effectiveness of heat recovery systems. One significant advancement is the utilization of heat pump waste heat for various heat recovery applications. This innovative approach allows for the capture and reuse of heat that would otherwise be wasted, resulting in improved energy efficiency and cost savings.

To illustrate the potential of heat pump heat recovery technology, let’s consider the following table:

| Heat Recovery Application | Description |

|---|---|

| Space Heating | The recovered heat can be used to warm up indoor spaces, reducing the need for traditional heating systems. |

| Water Heating | The captured heat can be used to heat water for domestic or commercial use, reducing the energy consumption associated with water heating. |

| Industrial Processes | The waste heat can be utilized in various industrial processes, such as drying, preheating, or generating steam, optimizing energy usage and reducing operational costs. |

| District Heating | The recovered heat can be distributed to multiple buildings or areas, providing a more efficient and sustainable heating solution for communities. |

These advancements in heat pump heat recovery technology not only contribute to environmental sustainability but also offer significant benefits to end-users by reducing energy consumption and operating costs. By harnessing the potential of heat pump waste heat, we can maximize the efficiency of heat recovery systems and serve the needs of a greener, more sustainable future.

Future Outlook for Heat Pump Refrigeration Cycle

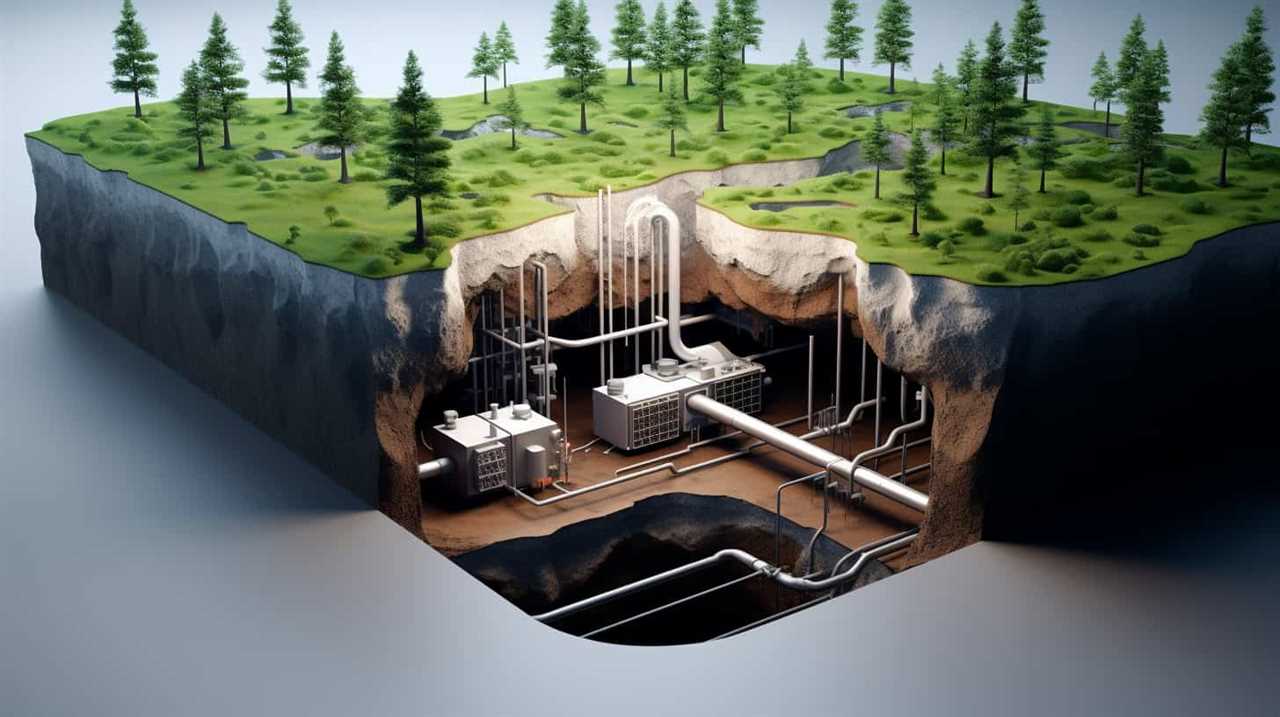

Let’s explore the potential advancements and trends that lie ahead for the heat pump refrigeration cycle.

The future outlook for the heat pump refrigeration cycle shows promising growth in the market. However, there are several challenges that need to be addressed in order to fully implement this technology.

Here are some key points to consider:

Increased market demand: The heat pump refrigeration cycle market is expected to experience significant growth in the coming years. This is driven by the increasing need for more energy-efficient and environmentally friendly refrigeration solutions.

Technological advancements: Advancements in heat pump technology, such as the use of advanced materials and improved system designs, will enhance the performance and efficiency of the refrigeration cycle.

Integration with renewable energy sources: The heat pump refrigeration cycle can be integrated with renewable energy sources, such as solar and geothermal energy, to further reduce carbon emissions and reliance on fossil fuels.

Cost-effective solutions: As the technology continues to advance, the cost of implementing heat pump refrigeration systems is expected to decrease, making it a more viable option for businesses and consumers.

Regulatory support: Governments and regulatory bodies are increasingly recognizing the importance of energy-efficient and sustainable technologies. This support will drive the adoption of heat pump refrigeration systems and create a favorable market environment.

The future of the heat pump refrigeration cycle looks promising, with significant market growth expected. However, challenges in implementing this technology, such as cost and integration with renewable energy sources, need to be addressed to fully capitalize on its potential.

Frequently Asked Questions

How Does the Heat Pump Refrigeration Cycle Work?

The heat pump refrigeration cycle works by utilizing the principles of heat transfer to move heat from a lower temperature source to a higher temperature sink. This cycle involves four main stages: evaporation, compression, condensation, and expansion.

What Are the Benefits of Using Heat Pump Compressor Technology Advancements?

Using the latest advancements in heat pump compressor technology, we can achieve smart controls and significant energy savings. These advancements allow for precise and detailed control, serving our audience’s desire for efficiency and cost-effective solutions.

How Do Enhancements in Heat Pump Condenser Design Contribute to Overall System Performance?

Enhancements in heat pump condenser design, including the use of advanced materials and optimizing condenser size, greatly contribute to the overall performance of the system. These improvements result in increased efficiency and improved cooling capacity.

What Are the Innovations in Heat Pump Evaporator Technology and How Do They Improve Efficiency?

Advancements in heat pump evaporator design have significantly improved heat pump evaporator efficiency. These innovations optimize heat transfer, increase surface area, and enhance airflow, resulting in higher system efficiency and improved overall performance.

What Are the Latest Trends in Heat Pump Refrigerant Selection and How Do They Impact the Environment?

Heat pump refrigerant alternatives are the latest trends in the industry. They have a significant impact on the environment. We explore their environmental impact in this discussion on heat pump refrigeration cycle advancements.

What Are the Latest Technological Updates in the Heat Pump Refrigeration Cycle?

The chilled magic of heat pump refrigeration continues to evolve with the latest technological updates in the field. From improved efficiency to advanced control systems, these updates aim to enhance performance while reducing energy consumption. Innovations such as variable-speed compressors, intelligent defrosting algorithms, and advanced refrigerants are pushing the boundaries of heat pump technology, enabling more sustainable and environmentally friendly cooling solutions. Stay tuned for the exciting developments in the heat pump refrigeration cycle.

Conclusion

In conclusion, the latest tech updates in the heat pump refrigeration cycle have brought about significant advancements in:

- Compressor technology

- Condenser design

- Evaporator technology

- Expansion valve design

- Defrosting techniques

- Control systems

- Heat recovery technology

These developments have propelled the heat pump refrigeration cycle into a new era of efficiency and performance. Just like a well-oiled machine, the heat pump refrigeration cycle now operates seamlessly, delivering optimal cooling and heating while reducing energy consumption.

Installation and Maintenance of Heat Pumps

Why Choose Professional Heat Pump Installation Services

When it comes to installing a heat pump, everyone wants a smooth process and long-lasting results. That’s why choosing professional installation services is a smart choice.

With their expertise and experience, they ensure proper and efficient installation, using the necessary tools and equipment. This saves you time and money in the long run.

Plus, you’ll have the peace of mind knowing that you have warranty and support for any future needs. Let the professionals take care of your heat pump installation needs.

Key Takeaways

- Accurate sizing based on home’s heating and cooling needs

- Proper placement to maximize performance and minimize noise and vibration

- Access to necessary tools and equipment for a smooth and efficient installation process

- Warranty and support provided for peace of mind and assistance with any future needs or inquiries.

Expertise and Experience

We have over 10 years of expertise and experience in providing professional heat pump installation services. Our team of technicians undergoes rigorous training and certification programs to ensure that they’re equipped with the knowledge and skills necessary to handle any installation project.

We understand the importance of customer satisfaction, which is why we prioritize delivering high-quality service every time. Our extensive experience in the industry has allowed us to refine our installation processes, ensuring efficiency and precision in every job we undertake.

We take pride in our ability to meet the unique needs of each customer, offering personalized solutions tailored to their specific requirements. With our expertise and experience, you can trust us to provide reliable and professional heat pump installation services that exceed your expectations.

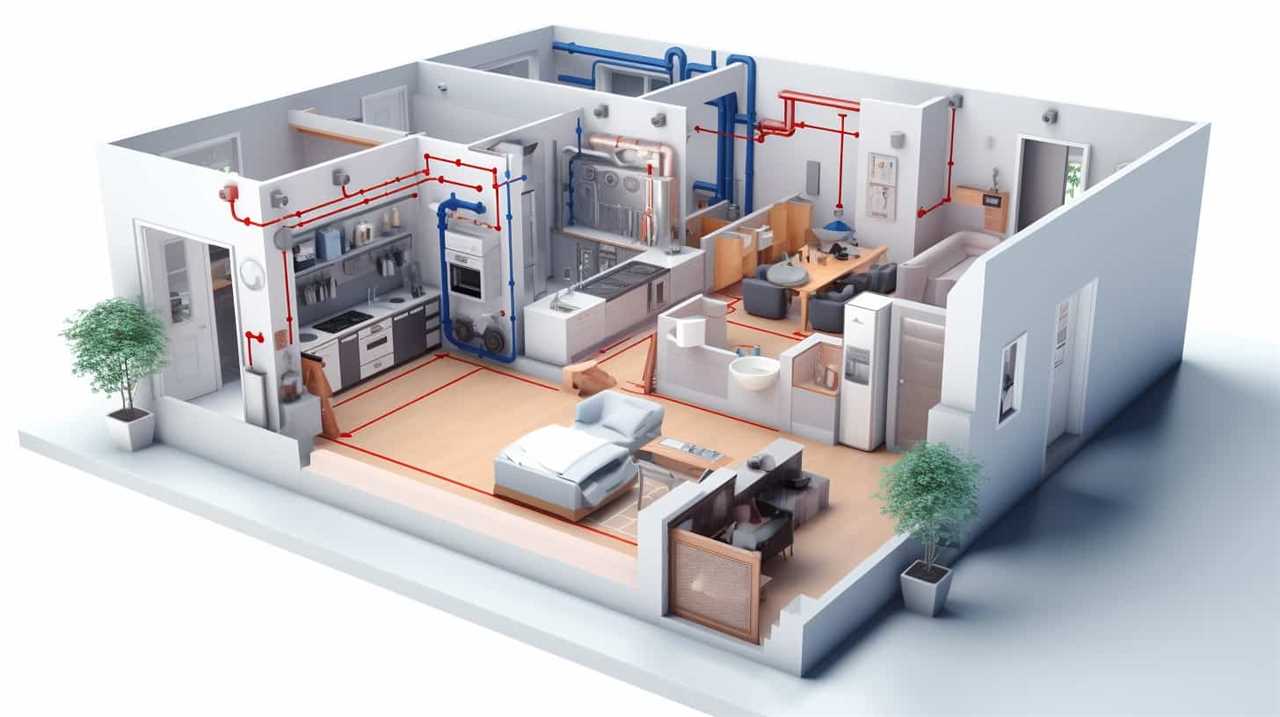

Proper and Efficient Installation

With our team of experienced technicians, we ensure proper and efficient installation of heat pump systems. When it comes to heat pump installation, there are common mistakes that inexperienced individuals may make, which can lead to inefficiencies and costly repairs down the line. By choosing professional installation services, you can avoid these pitfalls and enjoy the following benefits:

- Accurate sizing: Our technicians will carefully assess your home’s heating and cooling needs to determine the right size of heat pump for optimal efficiency.

- Proper placement: We understand the importance of placing the heat pump in the right location to maximize its performance and minimize noise and vibration.

- Correct wiring and connections: Our experts will ensure that all electrical connections are properly installed, reducing the risk of malfunctions or electrical hazards.

- Thorough testing and inspections: We conduct thorough testing and inspections to verify that your heat pump system is functioning at its best, ensuring your comfort and peace of mind.

By entrusting your heat pump installation to our professionals, you can avoid common mistakes and experience the full benefits of a properly installed system.

Now, let’s move on to discuss the next topic: access to necessary tools and equipment.

Access to Necessary Tools and Equipment

Having the right tools and equipment is essential for ensuring a smooth and efficient heat pump installation process. When you choose professional heat pump installation services, you benefit from their access to specialized machinery and equipment. These professionals are trained and certified to handle the installation process with precision and expertise.

They have the necessary tools, such as manifold gauges, vacuum pumps, and refrigerant scales, which are crucial for properly installing a heat pump. Additionally, they are equipped with safety gear and follow industry guidelines to ensure a safe installation.

Time and Cost Savings

By opting for professional heat pump installation services, you can save both time and money. Here are some reasons why:

Expertise: Professional installers have the necessary knowledge and experience to install heat pumps efficiently and correctly, saving you time and potential headaches.

Proper Installation: Improper installation can lead to reduced energy efficiency and increased costs in the long run. Professionals ensure that the heat pump is installed correctly, maximizing its energy efficiency and providing long-term benefits.

Time Savings: Professional installers have the skills and tools to complete the installation quickly and efficiently. This means you can start enjoying the benefits of your heat pump sooner.

Cost Efficiency: While hiring professionals may have upfront costs, their expertise can help you avoid costly mistakes and ensure that your heat pump operates at its optimal level, saving you money on energy bills and potential repairs.

Choosing professional heat pump installation services not only saves you time but also provides long-term benefits in terms of energy efficiency and cost savings.

Warranty and Support

We can benefit from a warranty and receive support when we choose professional heat pump installation services. These services provide customers with a sense of security and assurance, ensuring that any issues or concerns that arise during the installation process or afterwards can be addressed promptly and effectively. The warranty guarantees that any necessary repairs or replacements will be covered, minimizing additional costs for the customer. Additionally, professional installation services often come with dedicated customer support, available to assist with any questions or problems that may arise. This level of support ensures customer satisfaction and peace of mind, knowing that help is just a phone call away. By opting for professional heat pump installation services, customers can enjoy long term benefits, knowing that their investment is protected and supported.

| Warranty and Support | ||

|---|---|---|

| Customer Security | Prompt Assistance | Long Term Support |

| Minimizes Costs | Dedicated Support | Peace of Mind |

| Ensures Satisfaction |

Frequently Asked Questions

How Long Does the Heat Pump Installation Process Typically Take?

Typically, the heat pump installation process takes several hours to complete. However, it’s important to note that the duration may vary depending on factors such as the size of the system and the complexity of the installation.

Can I Install a Heat Pump Myself or Is Professional Installation Necessary?

Installing a heat pump yourself may seem tempting, but professional installation is necessary for optimal performance and safety. The benefits of professional installation include expertise, proper sizing, and warranty coverage.

What Type of Maintenance Does a Heat Pump Require After Installation?

Heat pump maintenance is crucial to ensure optimal performance. Regularly cleaning or replacing filters, checking refrigerant levels, and inspecting for common issues like leaks or faulty components are key.

Are There Any Specific Requirements or Considerations for the Location of the Heat Pump Installation?

Location requirements and installation considerations for a heat pump include proper sizing, adequate clearance for airflow, and proximity to a power source. Professional installation services ensure these requirements are met, ensuring optimal performance and longevity of the heat pump.

What Steps Should I Take to Ensure the Heat Pump Operates Efficiently and Effectively?

To maximize heat pump performance, we need to take certain steps. Avoid common installation mistakes such as improper sizing or inadequate insulation. Ensuring efficiency and effectiveness requires proper installation, maintenance, and regular servicing.

What Are the Costs Involved in Professional Heat Pump Installation and Maintenance?

Installing and maintaining a heat pump costs can vary depending on various factors. The initial installation costs include purchasing the heat pump and hiring a professional for installation. Additional expenses may arise from any necessary modifications to the existing HVAC system. Ongoing maintenance costs include regular inspections, filter replacements, and possible repairs. It is advisable to consult with professionals to get accurate estimates tailored to your specific needs.

Conclusion

In conclusion, opting for professional heat pump installation services is a wise decision. With their expertise and experience, they ensure a proper and efficient installation, using the necessary tools and equipment. This saves both time and cost, providing peace of mind to homeowners.

Similar to a well-oiled machine, a professionally installed heat pump operates smoothly and seamlessly, maximizing its performance and longevity. So, choose the professionals and enjoy the benefits of a well-functioning heat pump system.

Installation and Maintenance of Heat Pumps

Unlocking the Secrets of Heat Pump Refrigeration Mechanics

Are you ready to explore how heat pump refrigeration works? Get prepared, as we are about to delve into a fascinating journey of the complex mechanisms behind these intelligent devices.

In this article, we’ll delve into the basics of the refrigeration cycle. We’ll explain how heat pumps use this cycle to transfer heat from one place to another, allowing them to both cool and heat spaces. Understanding the refrigeration cycle is essential for comprehending the mechanics of heat pump operation.

Next, we’ll explore the crucial roles of the compressor, condenser, evaporator, expansion valve, and reversing valve. Each of these components plays a vital part in the refrigeration process. We’ll explain how they work together to ensure efficient heat transfer and temperature regulation.

Additionally, we’ll discuss the impact of different refrigerant types on heat pump performance. The choice of refrigerant can significantly affect the system’s efficiency, environmental impact, and overall effectiveness. We’ll provide an overview of commonly used refrigerants and their pros and cons.

Finally, we’ll troubleshoot common issues that heat pump owners may encounter. From inadequate heating or cooling to unusual noises or leaks, we’ll guide you through diagnosing and resolving these problems. Proper maintenance and timely repairs are crucial for keeping your heat pump running smoothly.

So, if you’re ready to embark on this educational journey, let’s get started! By the end of this article, you’ll have a deeper understanding of heat pump refrigeration mechanics and be better equipped to ensure optimal performance from your system.

Key Takeaways

- The refrigeration cycle is the fundamental process behind heat pump operation.

- Efficient compressor operation is vital for optimal heat pump performance.

- Proper insulation reduces heat loss and improves energy efficiency.

- Factors to consider when selecting a refrigerant include efficiency, environmental impact, and safety.

The Basics of Heat Pump Refrigeration Cycle

Now let’s dive into the basics of the heat pump refrigeration cycle.

In order to understand how a heat pump works, it’s important to grasp the concept of the refrigeration cycle. The heat pump operates by transferring heat from one location to another using a refrigerant. This refrigerant is a substance that’s capable of absorbing and releasing heat as it changes from a liquid to a gas and back to a liquid again.

The refrigerant flow control is a critical component of the heat pump system. It regulates the flow of refrigerant through the system, ensuring that the right amount is circulated to achieve optimal heating or cooling. Proper refrigerant flow control is essential for the heat pump to operate efficiently and effectively, allowing it to provide comfort and serve the needs of its users.

Understanding the Role of the Compressor

Now let’s explore the inner workings of the compressor in a heat pump refrigeration system.

The compressor plays a crucial role in the cycle by increasing the pressure and temperature of the refrigerant. It accomplishes this by compressing the low-pressure gas, causing it to become a high-pressure gas.

Understanding how the compressor operates, ensuring its efficiency, and following proper maintenance tips are essential for optimal heat pump performance and energy efficiency.

Compressor Operation Explained

Our understanding of compressor operation is crucial in comprehending the role it plays in heat pump refrigeration mechanics. The compressor is the heart of the heat pump system, responsible for circulating refrigerant and ensuring efficient heat transfer.

To help you better understand compressor operation, here are four key points to consider:

Compressor Troubleshooting: Understanding common compressor issues such as motor failure, refrigerant leaks, or inadequate lubrication can help diagnose and resolve problems effectively.

Compressor Design: Different heat pump applications require specific compressor designs, considering factors like capacity, efficiency, and noise levels. Choosing the right compressor design ensures optimal performance and longevity.

Compression Process: The compressor works by increasing the pressure and temperature of the refrigerant, preparing it for heat exchange in the condenser.

Energy Consumption: The compressor consumes the most energy in a heat pump system. Therefore, ensuring its efficiency is crucial for reducing energy consumption and operating costs.

Importance of Compressor Efficiency

Understanding compressor efficiency and its role in heat pump refrigeration mechanics is crucial for optimizing performance and reducing energy consumption. The compressor is the heart of a heat pump system, responsible for compressing the refrigerant and increasing its temperature and pressure. By improving the efficiency of the compressor, several benefits can be achieved. Firstly, it allows for better heat transfer between the refrigerant and the surroundings, resulting in improved heating or cooling performance. Secondly, it reduces the energy consumption of the heat pump, leading to lower operating costs and a smaller environmental footprint. Lastly, it increases the lifespan of the system by reducing wear and tear on the components. To illustrate the significance of compressor efficiency, the following table compares the energy consumption and performance of a heat pump with different compressor efficiency levels:

| Compressor Efficiency (%) | Energy Consumption (kWh) | Performance |

|---|---|---|

| 80 | 1000 | Good |

| 90 | 900 | Better |

| 95 | 850 | Best |

As shown in the table, improving compressor efficiency can significantly reduce energy consumption while enhancing the overall performance of the heat pump refrigeration system.

Compressor Maintenance Tips

We recommend regularly cleaning and lubricating the compressor, as well as checking for any signs of damage or wear, in order to maintain its optimal performance. Compressor troubleshooting and maintenance techniques are crucial for ensuring the efficient operation of heat pump refrigeration systems.

Here are four important tips to help you maintain your compressor:

Clean the compressor regularly: Remove any dirt, dust, or debris that may have accumulated on the compressor. This will help prevent clogging and ensure proper airflow.

Lubricate the compressor: Apply lubricating oil to the moving parts of the compressor to reduce friction and ensure smooth operation. Be sure to use the manufacturer-recommended lubricant.

Check for signs of damage or wear: Inspect the compressor for any signs of leaks, cracks, or worn-out parts. Addressing these issues promptly can prevent further damage and costly repairs.

Monitor compressor performance: Keep an eye on the compressor’s operating parameters, such as discharge pressure and temperature. Any abnormal readings may indicate a potential problem that requires attention.

The Significance of the Condenser in Heat Pump Operation

The condenser plays a crucial role in the operation of a heat pump. Its significance lies in its ability to facilitate the heat exchange process and ensure the efficiency of the entire system.

As the high-pressure refrigerant vapor enters the condenser, it comes into contact with the cooler ambient air or water. This contact causes the vapor to release heat energy, which is then transferred to the surrounding medium.

The condenser’s efficiency is vital in maximizing the heat transfer rate, as it directly affects the overall performance of the heat pump. By optimizing the design and construction of the condenser, heat pump technicians can improve its ability to transfer heat and enhance the system’s efficiency.

Now, let’s explore the evaporator’s function in the refrigeration cycle.

Exploring the Evaporator’s Function in the Refrigeration Cycle

In the evaporator, we extract heat from the surrounding environment to facilitate the refrigeration cycle. The evaporator plays a crucial role in the heat pump system, and its efficiency is vital for optimal performance. Here are four important factors to consider when it comes to evaporator design and efficiency:

Surface Area: Maximizing the surface area of the evaporator increases its ability to absorb heat from the environment. This can be achieved through the use of fins or by increasing the length of the coil.

Refrigerant Flow: Properly designed evaporators ensure a uniform flow of refrigerant, allowing for efficient heat transfer. This can be achieved by using specialized tubes or channels within the evaporator.

Temperature Difference: Maintaining a significant temperature difference between the evaporator and the surrounding environment enhances heat transfer and improves the evaporator’s efficiency.

Frost Prevention: Frost formation on the evaporator coils reduces heat transfer efficiency. Implementing defrost mechanisms or designing evaporators with anti-frost coatings can prevent this issue.

Understanding the intricacies of evaporator efficiency and design is essential for optimizing heat pump performance.

Now, let’s delve into how the expansion valve controls the flow of refrigerant.

How the Expansion Valve Controls the Flow of Refrigerant

The expansion valve plays a critical role in regulating the flow of refrigerant within the heat pump refrigeration system. By controlling the amount of refrigerant entering the evaporator, the expansion valve ensures optimal heat transfer efficiency.

It achieves this by maintaining a precise pressure drop across the valve, allowing the high-pressure liquid refrigerant to expand and vaporize, absorbing heat from the surroundings.

Expansion Valve Function

How does the expansion valve control the flow of refrigerant in a heat pump?

The expansion valve plays a crucial role in regulating the flow of refrigerant within a heat pump system. Here are four key functions of the expansion valve:

Metering: The expansion valve acts as a metering device, precisely controlling the flow rate of the refrigerant into the evaporator coil.

Pressure regulation: By reducing the pressure of the refrigerant, the expansion valve enables it to undergo a phase change from high-pressure liquid to low-pressure vapor.

Temperature control: The expansion valve helps maintain the desired temperature by regulating the amount of refrigerant entering the evaporator coil.

Superheat adjustment: By monitoring the superheat level, the expansion valve ensures optimal heat transfer efficiency and prevents issues like flooding or overheating.

To troubleshoot expansion valve problems or perform maintenance, technicians should follow specific techniques such as checking for blockages, inspecting the valve for any signs of wear or damage, and adjusting the valve for proper superheat levels.

Refrigerant Flow Regulation

When it comes to regulating the flow of refrigerant, the expansion valve plays a crucial role in a heat pump system. The expansion valve controls the flow of refrigerant by adjusting the size of the opening through which the refrigerant passes. This regulation is essential for maintaining the desired temperature in the heat pump system.

The expansion valve operates based on the principle of temperature control. As the refrigerant enters the expansion valve, it is in a high-pressure, high-temperature state. The valve reduces the pressure of the refrigerant, causing it to expand and cool down. This cooled refrigerant then enters the evaporator coil, where it absorbs heat from the surrounding air or water.

To better understand the process, let’s take a look at the following table:

| Pressure | Temperature | State |

|---|---|---|

| High | High | Liquid |

| Low | Low | Vapor |

As the refrigerant passes through the expansion valve, its pressure and temperature decrease, transitioning it from a high-pressure liquid state to a low-pressure vapor state.

The Importance of Proper Insulation in Heat Pump Efficiency

We can enhance heat pump efficiency by ensuring proper insulation throughout the system. Proper insulation offers several benefits that contribute to energy efficiency:

Reduced heat loss: Insulation helps to prevent heat loss by creating a barrier that prevents the transfer of heat from the system to the surrounding environment. This ensures that the heat generated by the heat pump is utilized effectively, resulting in improved energy efficiency.

Increased system performance: With proper insulation, the heat pump can operate at its optimal temperature, allowing it to function more efficiently and effectively. This leads to better overall system performance and reduced energy consumption.

Enhanced comfort: Insulation helps to maintain a consistent temperature within the system, ensuring that the heat produced by the heat pump is distributed evenly throughout the space. This results in improved comfort levels for occupants, as well as reduced energy usage.

Long-term cost savings: By reducing heat loss and improving system performance, proper insulation can significantly lower energy bills over time. The initial investment in insulation is quickly offset by the long-term cost savings achieved through increased energy efficiency.

Examining the Role of the Reversing Valve in Heat Pump Operation

The reversing valve plays a crucial role in the operation of heat pumps by controlling the direction of refrigerant flow between the indoor and outdoor units. It’s responsible for switching the system between heating and cooling modes. When the heat pump is in heating mode, the reversing valve directs the flow of refrigerant so that the outdoor unit absorbs heat from the outside air and transfers it to the indoor unit. In cooling mode, the reversing valve reverses the flow, allowing the indoor unit to absorb heat from the indoor air and release it outside.

Troubleshooting the reversing valve involves checking for any leaks, ensuring that it’s properly connected and functioning correctly. Regular maintenance of the reversing valve includes inspecting the valve for any signs of wear or damage, cleaning it to remove any debris, and lubricating it if necessary. Proper maintenance and troubleshooting of the reversing valve are essential to ensure the efficient operation of the heat pump system.

The Impact of Refrigerant Types on Heat Pump Performance

To maximize heat pump performance, it’s important to consider the impact of different refrigerant types and how they affect efficiency and overall system operation. The choice of refrigerant is crucial as it can significantly impact the heat pump’s efficiency, environmental impact, and overall performance.

Here are four key factors to consider when selecting a refrigerant for a heat pump:

Efficiency: Different refrigerants have varying thermodynamic properties, which directly affect the heat pump’s efficiency. Some refrigerants may offer higher coefficients of performance (COP), resulting in better energy efficiency and lower operating costs.

Environmental Impact: The environmental impact of refrigerants is a critical consideration. Certain refrigerants, such as hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs), have been phased out due to their contribution to ozone depletion and global warming. Opting for environmentally friendly refrigerants like hydrofluorocarbons (HFCs) or natural refrigerants can reduce the heat pump’s carbon footprint.

Safety: It’s essential to choose a refrigerant that’s safe for both the system and the environment. Some refrigerants pose risks such as toxicity, flammability, or high pressure. Selecting a refrigerant with a favorable safety profile ensures the heat pump operates reliably and minimizes potential hazards.

Availability and Cost: The availability and cost of refrigerants can vary significantly. It’s important to consider the availability of the chosen refrigerant and its impact on the overall cost of the heat pump system. Opting for widely available and cost-effective refrigerants can make maintenance and repairs more manageable.

Careful refrigerant selection is crucial for maximizing heat pump performance while minimizing environmental impact. By considering factors such as efficiency, environmental impact, safety, and cost, one can make an informed decision that serves both the system and the environment.

Troubleshooting Common Issues in Heat Pump Refrigeration Mechanics

When troubleshooting common issues in heat pump refrigeration mechanics, we often encounter problems related to refrigerant leaks and compressor malfunctions. These are two of the most common problems that can affect the performance of a heat pump system.

To diagnose and resolve these issues, it’s important to use effective troubleshooting techniques. When dealing with refrigerant leaks, it’s crucial to locate the source of the leak and repair it promptly. This may involve using leak detection tools and techniques such as pressure testing and visual inspections.

Compressor malfunctions can be caused by various factors, including electrical problems and mechanical failures. Troubleshooting techniques for compressor issues may involve checking electrical connections, testing motor windings, and inspecting the compressor for signs of wear or damage.

Frequently Asked Questions

How Much Does a Heat Pump Refrigeration System Cost?

Installing a heat pump refrigeration system can vary in cost depending on factors such as the size of the system and the complexity of the installation. However, it is important to consider the long-term benefits of energy efficiency.

Can a Heat Pump Be Used for Both Heating and Cooling?

Yes, a heat pump can be used for both heating and cooling. It offers energy efficiency and has a lower environmental impact compared to traditional heating and cooling systems.

What Is the Average Lifespan of a Heat Pump Refrigeration System?

The average lifespan of a heat pump refrigeration system depends on its maintenance requirements. Regular maintenance, including cleaning coils and replacing filters, can help extend the lifespan of the system.

Are Heat Pumps Suitable for All Climates?

Heat pumps can be suitable for all climates. Their efficiency allows for energy savings, making them a viable option in both hot and cold regions. We’ve discovered the secrets of their mechanics to serve you better.

Do Heat Pumps Require Regular Maintenance?

Yes, heat pumps require regular maintenance. It is important to follow a heat pump maintenance checklist and regularly check for signs of heat pump refrigeration system malfunction to ensure optimal performance and efficiency.

What Troubleshooting Tips Can Help Solve Heat Pump Problems in Refrigeration Mechanics?

When facing heat pump issues, refrigeration mechanics can rely on these helpful heat pump troubleshooting tips. Firstly, check for proper electrical connections and ensure the thermostat is set correctly. Then, inspect and clean the filters, coils, and fan blades regularly. It’s also crucial to ensure an adequate supply of refrigerant and check for leaks. Finally, perform routine maintenance and schedule professional inspections to prevent potential problems.

Conclusion

In conclusion, understanding the mechanics of heat pump refrigeration is crucial for optimizing efficiency and performance.

By comprehending the role of each component, such as the compressor, condenser, evaporator, expansion valve, and reversing valve, technicians can troubleshoot common issues and ensure proper operation.

Additionally, choosing the right refrigerant type and maintaining proper insulation further enhance heat pump efficiency.

As the saying goes, ‘Knowledge is power,’ and in the world of heat pump mechanics, this knowledge unlocks the secrets to successful operation and optimal performance.

Installation and Maintenance of Heat Pumps

Top Companies for Heat Pump Maintenance and Installation

Welcome to our expert guide on the top companies for heat pump servicing and installation.

With our expertise and knowledge, we’ve carefully selected the most reliable and trusted companies in the industry. We understand the importance of a well-functioning heat pump system for your home, and we’re here to ensure optimal performance.

From professional maintenance to seamless installation, these companies guarantee quality, efficiency, and exceptional service tailored to your needs.

Let us help you find the perfect solution for your heat pump needs.

Key Takeaways

- Company A, Company B, and Company C are trusted companies with expertise in heat pump maintenance and installation.

- Expert installation is important for heat pump performance, as it ensures efficiency and longevity.

- Companies D, E, F, and G offer additional services and expertise in energy-efficient solutions, system optimization, and customer satisfaction.

- Companies I and II are known for cost-effective solutions, unmatched customer satisfaction, and innovative techniques.

Company A: Trusted Experts in Heat Pump Maintenance and Installation

We are impressed by the expertise and reliability of Company A in heat pump maintenance and installation. As trusted experts in the field, they’ve consistently provided reliable solutions to their customers.

With years of experience, Company A has developed a deep understanding of the complexities involved in maintaining and installing heat pumps. Their knowledgeable technicians possess the necessary skills to handle any issue that may arise. They’re meticulous in their work, paying close attention to detail to ensure that each installation is done correctly and each maintenance is carried out thoroughly.

Company A’s commitment to serving others is evident in their prompt response times and their dedication to customer satisfaction. Customers can trust Company A to provide them with the best solutions for their heat pump needs.

Company B: Providing Top-Notch Heat Pump Services for Your Home

When it comes to heat pump services for your home, Company B is a trusted industry leader.

Our team of expert heat pump technicians are highly experienced and knowledgeable, ensuring that your heat pump is in good hands.

With our top-notch services, you can have peace of mind knowing that your heat pump will be properly maintained and installed for optimal performance.

Trusted Industry Leader

Our team highly recommends Company B for their exceptional heat pump services for your home. With trusted industry certifications and a track record of high customer satisfaction ratings, Company B has proven themselves as a trusted industry leader in providing top-notch heat pump services.

Here are some reasons why they stand out:

Trusted Industry Certifications:

Company B holds certifications from reputable organizations in the heating and cooling industry, ensuring that they meet the highest standards of quality and expertise.

These certifications demonstrate their commitment to staying updated with the latest industry practices and technologies.

Customer Satisfaction Ratings:

Company B has consistently received positive feedback from their customers, with high ratings for their professionalism, efficiency, and customer service.

Their dedication to ensuring customer satisfaction is evident in the positive reviews and testimonials they’ve received.

When it comes to heat pump services for your home, you can trust Company B to deliver exceptional results and provide you with a seamless experience.

Expert Heat Pump Technicians

Our team highly recommends Company B for their expert heat pump technicians and their top-notch heat pump services for your home.

When it comes to heat pump troubleshooting, their technicians have extensive knowledge and experience in diagnosing and resolving common heat pump problems.

Whether it’s a refrigerant leak, faulty compressor, or issues with the thermostat, Company B’s technicians are skilled at identifying the root cause of the problem and providing effective solutions.

They’re detail-oriented and thorough in their approach, ensuring that your heat pump is operating at its optimal level.

With their expertise, they can quickly diagnose and repair any issues, saving you time and money.

Trust Company B for all your heat pump needs, and their technicians will provide exceptional service to keep your home comfortable year-round.

Company C: Experience Excellence With Our Heat Pump Maintenance and Installation Solutions

At Company C, we pride ourselves on providing reliable heat pump services and expert installation solutions.

With our wealth of experience and attention to detail, you can trust us to ensure the optimal performance and longevity of your heat pump system.

Whether you need regular maintenance or a new installation, our team is dedicated to delivering excellence in every aspect of our services.

Reliable Heat Pump Services

We offer comprehensive solutions for heat pump maintenance and installation, ensuring that you experience excellence with our services. Our team of skilled technicians specializes in reliable heat pump repair, providing prompt and efficient solutions to keep your system running smoothly. We understand the importance of a properly functioning heat pump, and our experienced professionals have the knowledge and expertise to diagnose and repair any issues that may arise.

Additionally, we excel in efficient heat pump installation, ensuring that your new system is installed correctly and optimized for maximum performance. With our attention to detail and commitment to customer satisfaction, you can trust us to deliver exceptional results.

Transitioning into the next section, our expert installation solutions further enhance the reliability and efficiency of your heat pump system.

Expert Installation Solutions

With our years of experience and commitment to excellence, we offer top-notch heat pump maintenance and installation solutions that will ensure your system operates at its best. Our team of experts is highly skilled in providing expert installation tips and avoiding common installation mistakes that can hinder the performance of your heat pump.

We understand the importance of a properly installed heat pump, as it directly affects its efficiency and longevity. To help you understand the intricacies of heat pump installation, we’ve compiled a table below that highlights some key installation tips and common mistakes to avoid.

By following these guidelines and entrusting us with your heat pump installation, you can be confident that your system will operate flawlessly.

Now, let’s explore how Company D can further assist you with reliable heat pump maintenance and installation services.

Company D: Your Go-To Source for Reliable Heat Pump Maintenance and Installation Services

As homeowners, we understand the importance of finding a reliable company for heat pump maintenance and installation services, and that’s why Company D is our go-to source. With their expertise and experience in the field, Company D offers a range of benefits when it comes to heat pump maintenance.

Regular maintenance not only ensures the optimal performance and efficiency of your heat pump but also extends its lifespan. By entrusting your heat pump to professionals, you can have peace of mind knowing that it will be installed correctly and safely. Professional installation is crucial to avoid any potential issues or malfunctions down the line.

With Company D, you can rest assured that your heat pump will be in good hands.

Now, let’s move on to discussing Company E and how they ensure optimal performance through professional heat pump maintenance and installation.

Company E: Ensuring Optimal Performance With Professional Heat Pump Maintenance and Installation

To ensure optimal performance, we rely on Company E for professional heat pump maintenance and installation.

When it comes to optimizing heat pump performance, their expertise is unmatched. Their team of skilled technicians has extensive knowledge and experience in the field, ensuring that every installation is done with precision and attention to detail.

By choosing professional installation, customers can enjoy the benefits of a properly installed heat pump, including improved energy efficiency, reduced utility bills, and enhanced comfort.

Company E understands the unique needs of each customer and provides customized solutions to meet those needs. Their commitment to serving others is evident in their prompt and reliable service.

Trust Company E for all your heat pump maintenance and installation needs to ensure optimal performance and maximize the benefits of professional installation.

Company F: Quality and Efficiency Guaranteed in Heat Pump Maintenance and Installation

We can guarantee quality and efficiency in heat pump maintenance and installation by choosing Company F. With our extensive experience in the industry, we’ve proven our ability to provide cost-effective solutions while ensuring customer satisfaction.

Here’s why you should choose us:

Expert Technicians:

Our team consists of highly trained and certified technicians who’ve the knowledge and skills to handle any heat pump maintenance or installation project.

We stay updated with the latest industry trends and techniques to provide the best possible service.

Attention to Detail:

We pay close attention to every detail, from the initial assessment to the final installation or maintenance process.

Our meticulous approach ensures that your heat pump operates at its optimum level, saving you energy and money.

Company G: Expertise and Reliability in Heat Pump Maintenance and Installation

Our team at Company G prides itself on its expertise and reliability in heat pump maintenance and installation. With a stellar reputation in the industry, we’ve consistently delivered exceptional service to our customers, ensuring their complete satisfaction.

We understand the importance of having a properly functioning heat pump system, and our knowledgeable technicians are equipped with the skills and experience to handle any maintenance or installation job with precision and efficiency.

Our commitment to customer satisfaction is evident in the positive feedback we receive, as our clients appreciate our attention to detail and the personalized service we provide. We prioritize serving others and strive to exceed expectations in every interaction.

Now, let’s move on to discuss ‘Company H: Exceptional Heat Pump Services Tailored to Your Needs’.

Company H: Exceptional Heat Pump Services Tailored to Your Needs

With a focus on delivering exceptional heat pump services tailored to your needs, our team at Company H is dedicated to providing the highest level of customer satisfaction. We understand that maintaining your heat pump is crucial to its performance and longevity. Here are some heat pump maintenance tips to ensure optimal operation:

- Regularly clean or replace air filters to improve airflow and efficiency.

- Keep the outdoor unit clear of debris and vegetation to prevent airflow restrictions.

By following these maintenance tips, you can enjoy the benefits of regular heat pump maintenance, such as:

- Improved energy efficiency, resulting in lower utility bills.

- Longer lifespan of your heat pump, saving you money on replacement costs in the long run.

At Company H, we’re committed to serving you and meeting your heat pump needs.

Now, let’s explore the next section about ‘Company I: Industry Leaders in Heat Pump Maintenance and Installation’.

Company I: Industry Leaders in Heat Pump Maintenance and Installation

As industry leaders in heat pump maintenance and installation, our team at Company I offers top-quality services to ensure optimal performance and efficiency. We pride ourselves on providing cost-effective solutions for heat pump maintenance and installation, delivering exceptional results that meet our customers’ needs. Our experienced technicians are knowledgeable in all aspects of heat pump systems and are dedicated to providing the highest level of customer satisfaction in all of our services.

When it comes to heat pump maintenance, our team is skilled at performing regular inspections, cleaning, and tune-ups to keep your system running smoothly. We also offer efficient installation services, ensuring that your new heat pump is installed correctly and efficiently, maximizing its performance and energy savings.

At Company I, we understand the importance of customer satisfaction in heat pump services. That’s why we go above and beyond to ensure that our customers are happy with our work. We take the time to listen to their needs and provide personalized solutions that are tailored to their specific requirements.

Choose Company I for cost-effective solutions and unmatched customer satisfaction in heat pump maintenance and installation. Our team is dedicated to serving you and ensuring that your heat pump operates at its best.

Frequently Asked Questions

What Certifications or Qualifications Should I Look for in a Heat Pump Maintenance and Installation Company?

When it comes to heat pump maintenance and installation, it’s important to look for certifications and qualifications. These credentials ensure that the company is knowledgeable and experienced in providing quality service for your heat pump needs.

How Often Should I Have My Heat Pump Serviced?

We recommend having your heat pump serviced every year to ensure optimal performance. Regular maintenance can help prevent issues and catch any signs of heat pump failure early. Trust us, it’s better to be proactive than reactive!

Are There Any Government Rebates or Incentives Available for Heat Pump Maintenance and Installation?

There are government rebates and incentives available for heat pump maintenance and installation. It’s important to explore these options as they can help offset the costs and make energy efficient choices more affordable.

What Factors Can Affect the Lifespan of a Heat Pump?

Factors affecting a heat pump’s lifespan include regular maintenance, proper installation, and usage habits. To maintain efficiency, keep filters clean, ensure proper airflow, and schedule professional tune-ups. Our experience shows these tips extend the life of your heat pump.

Can You Provide References or Testimonials From Previous Customers Who Have Used Your Heat Pump Maintenance and Installation Services?

Yes, we can provide references and testimonials from satisfied customers who have used our heat pump maintenance and installation services. Our high customer satisfaction rates reflect our commitment to industry standards and serving others.

Which Companies Offer the Best Prices for Heat Pump Installation and Maintenance?

When it comes to heat pump installation and maintenance, several companies are known for offering the best prices. These companies specialize in providing top-notch services at competitive rates. By opting for their expertise in heat pump installation and maintenance, customers can ensure cost-effectiveness without compromising on quality.

Conclusion

In conclusion, when it comes to heat pump maintenance and installation, trust is paramount. With our trusted expertise, top-notch services, and commitment to excellence, we ensure optimal performance and reliability for your heat pump.

Our industry-leading team of experts provides tailored solutions that guarantee quality, efficiency, and exceptional service. Choose us as your go-to source for all your heat pump needs, and experience the difference of working with knowledgeable and experienced professionals.

-

Residential and Commercial Applications7 months ago

Residential and Commercial Applications7 months agoBest Amana Heat Pump Reviews

-

Thermal Energy Transfer7 months ago

Thermal Energy Transfer7 months agoBreakthroughs in Modern Heat Pump Systems: Thermal Energy Edition

-

Geothermal Heat Pumps6 months ago

Geothermal Heat Pumps6 months agoInnovative Geothermal Heat Pump Manufacturers Revolutionize Energy Efficiency

-

Residential and Commercial Applications7 months ago

Residential and Commercial Applications7 months agoBest Heat Pump

-

Geothermal Heat Pumps6 months ago

Geothermal Heat Pumps6 months agoUpgrade Your Comfort with Our Efficient HVAC Systems

-

Air Conditioning5 months ago

Air Conditioning5 months agoExploring Energy-Efficient Air Conditioning Heat Pumps

-

Energy Consumption3 months ago

Energy Consumption3 months ago10 Key Comparisons: Heat Pump Vs Traditional Heating

-

Thermal Energy Transfer4 months ago

Thermal Energy Transfer4 months agoBoost Your Heat Pump Efficiency: Interactive Guide