To enhance heat transfer efficiency in heat pumps, you can incorporate innovative geometric designs like microchannels, spiral fins, and biomimetic structures, which disrupt flow and increase turbulence. Using advanced materials and coatings such as graphene or nano-embossed surfaces boosts thermal conductivity and reduces fouling. Implementing phase change materials and nanofluids further improves performance. Combining these strategies with computational models helps optimize your system. Explore these options to gain access to higher efficiency and reliability in your heat pump applications.

Key Takeaways

- Utilize advanced geometric designs like microchannels, spiral fins, and biomimetic structures to increase surface area and turbulence.

- Apply nanostructured and high-conductivity coatings (e.g., graphene, silver) to reduce thermal resistance and enhance heat transfer.

- Incorporate phase change materials and nanofluids to improve thermal capacity and boost overall heat exchange efficiency.

- Optimize heat exchanger geometries through numerical simulations and CFD for maximum performance tailored to specific applications.

- Implement surface treatments and material selections that minimize fouling, improve durability, and maintain high heat transfer rates over time.

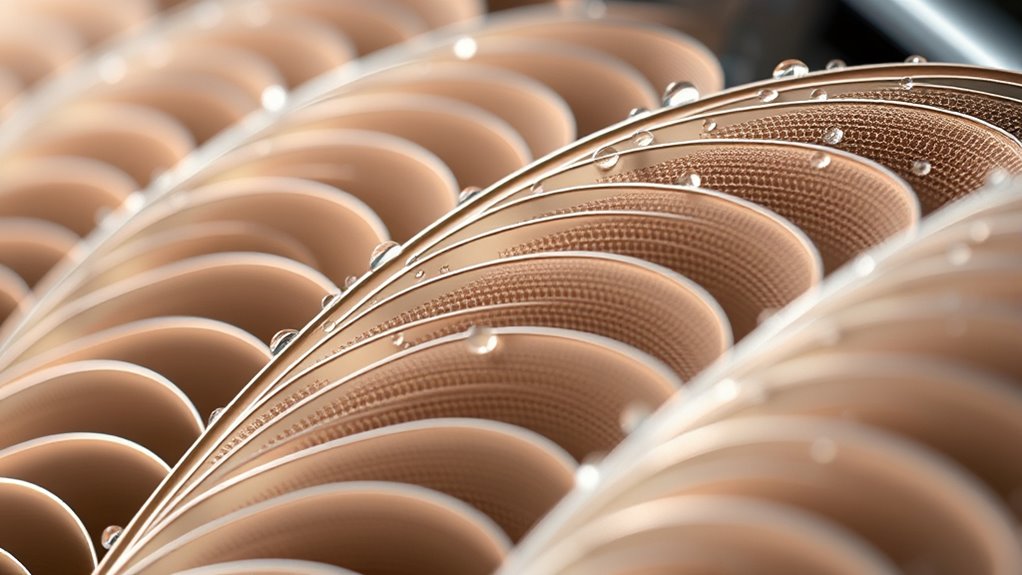

Innovative Geometric Designs for Heat Exchangers

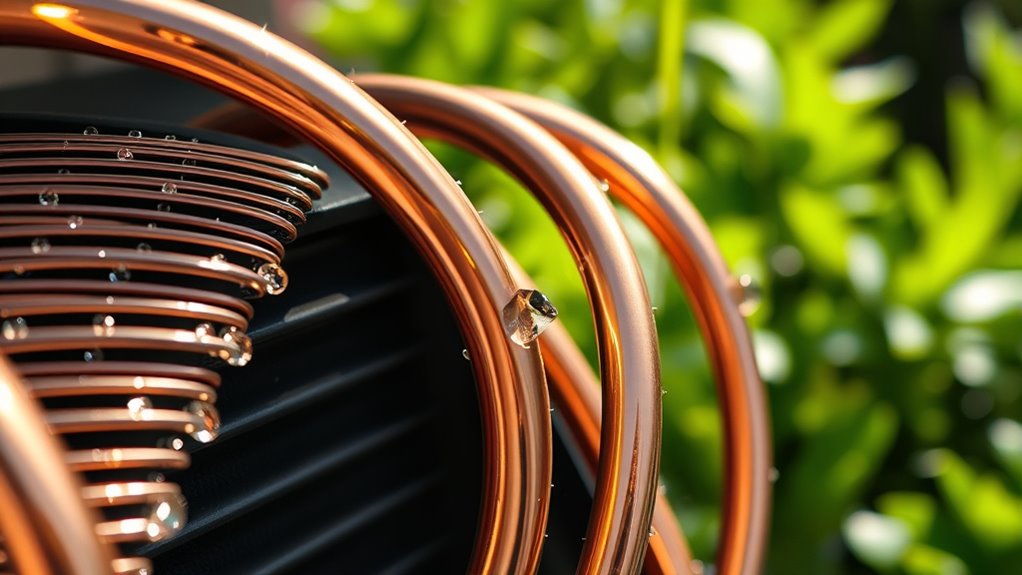

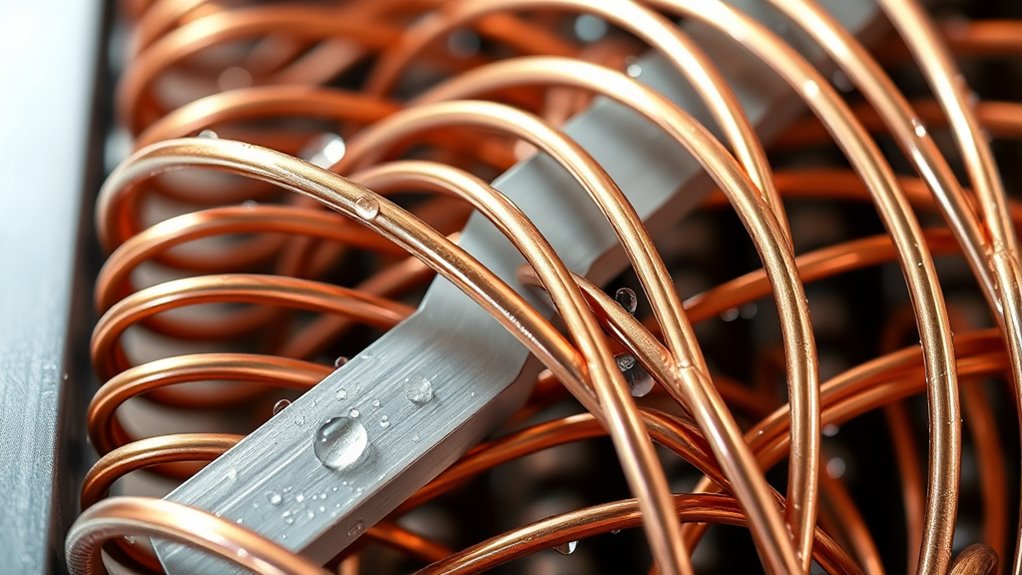

Innovative geometric designs are transforming heat exchanger efficiency by enhancing surface area and turbulence. Spiral fins on heat exchangers, with a 40 mm pitch, boost heat transfer by increasing contact and flow disruption, outperforming traditional setups. Advanced geometries, like microchannel and mini-channel designs, dramatically reduce size while delivering 2–3 times higher heat transfer coefficients. Variable cross-sectional tubes, including flat and alternating shapes, further improve thermal performance, with heat transfer coefficients rising up to 60%. Spiral and double spiral geometries also elevate turbulence, which enhances the heat transfer coefficient and overall efficiency. These innovative geometries optimize surface area and fluid flow, resulting in better heat transfer, improved performance, and more compact, effective heat exchangers. Incorporating enhanced turbulence techniques can further amplify heat transfer rates in these designs. Additionally, the integration of noise reduction technologies ensures these high-performance systems operate quietly, maintaining comfort while maximizing efficiency. Moreover, selecting appropriate materials that have superior thermal conductivity can further boost the overall heat transfer performance of these systems. Material selection plays a crucial role in achieving optimal thermal performance and durability of heat exchangers.

Advanced Materials and Coatings to Boost Conductivity

Building on recent advances in geometric design, selecting advanced materials and coatings plays a vital role in further enhancing heat exchanger performance. Nanostructured coatings, such as nano-embossed or textured surfaces, increase surface area and turbulence, boosting heat transfer enhancement. High-conductivity coatings like graphene or silver markedly improve thermal conductivity, reducing thermal resistance and increasing efficiency by up to 30%. Surface modification with nano-embossed coatings minimizes fouling and maintains peak thermal performance over time. Incorporating phase change materials into coatings enables dynamic thermal regulation, maintaining ideal operating temperatures. Advanced ceramic coatings with high thermal stability and low emissivity reduce heat losses in high-temperature sections. Proper surface treatment techniques can significantly improve the longevity and effectiveness of these coatings in demanding environments. Additionally, employing advanced diagnostic tools allows for precise assessment and optimization of coating performance during operation. Implementing innovative material selection ensures that coatings can withstand harsh conditions and extend service life. Utilizing surface characterization methods further enhances understanding of coating behavior under operational stresses, leading to more durable solutions. Moreover, integrating thermal modeling techniques can predict performance outcomes and guide the development of more efficient coatings. These innovative materials and surface modifications optimize heat exchanger surfaces, delivering superior thermal performance and energy efficiency.

Microchannel and Mini-Channel Heat Exchanger Technologies

Microchannel and mini-channel heat exchangers offer higher heat transfer rates due to their increased surface area-to-volume ratio. Their compact design allows for efficient heat exchange in smaller systems, reducing size and material use. With advanced manufacturing, these technologies deliver superior thermal performance and system efficiency. Additionally, filtration systems, such as those incorporating specialized materials, can be integrated to enhance system longevity and performance. The use of material selection in manufacturing further optimizes heat transfer and durability of these exchangers.

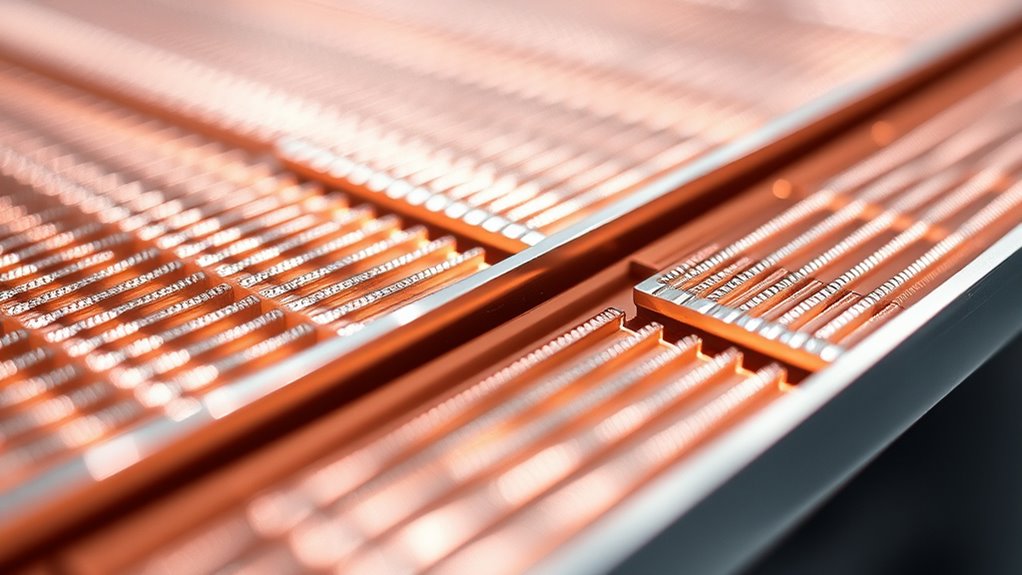

High Heat Transfer Rates

High heat transfer rates are a key advantage of microchannel and mini-channel heat exchanger technologies, thanks to their small hydraulic diameters typically ranging from 1 to 3 millimeters. These compact heat exchangers boost the heat transfer coefficient, enabling a higher heat transfer rate and improved thermal performance. Their increased surface area-to-volume ratio enhances thermal exchange while reducing size and weight. Precise manufacturing ensures ideal flow distribution and minimizes thermal resistance, further elevating energy efficiency. This results in significant improvements in heat pump efficiency. The table below highlights key aspects:

| Feature | Benefit |

|---|---|

| Small hydraulic diameter | Higher heat transfer coefficient |

| Surface area-to-volume ratio | Enhanced thermal exchange |

| Precise fabrication | Reduced thermal resistance, better flow distribution |

| Thermal performance | Up to 50% improvement, increased energy efficiency |

Additionally, the thermal conductivity of materials used plays a crucial role in maximizing heat transfer efficiency. Achieving material selection is essential for further enhancing the overall thermal performance of heat exchangers. Proper fluid dynamics within the channels also contribute significantly to optimizing heat transfer rates. It is important to consider manufacturing accuracy to ensure consistent performance across units. Moreover, ongoing research into advanced manufacturing techniques promises to further improve the precision and performance of these heat exchangers.

Compact System Design

The compact design of microchannel and mini-channel heat exchangers allows you to achieve high thermal performance within limited space. These advanced heat transfer solutions enable the development of truly compact heat pump systems by maximizing heat transfer coefficients and system miniaturization. Microchannel heat exchangers, utilizing mini-channel technology, deliver up to five times higher heat transfer efficiency than traditional designs. Their small hydraulic diameters improve flow distribution and reduce fouling, enhancing durability. With precise manufacturing techniques, you can guarantee consistent performance and longevity. This compact system design not only saves space but also enhances overall efficiency by enabling better thermal performance in tight environments. GMC tuning techniques can be integrated to optimize system performance further, ensuring maximum efficiency and durability. Additionally, the use of advanced manufacturing methods ensures tight tolerances for optimal heat transfer and reliability. Incorporating innovative materials can also improve corrosion resistance and thermal conductivity, further boosting system longevity. Leveraging thermal management strategies can additionally help maintain optimal operating conditions and extend system lifespan. Moreover, understanding heat transfer mechanisms is essential for designing systems that maximize performance while minimizing size.

Biomimetic Structures and Fin Optimization Strategies

Biomimetic structures, inspired by nature’s efficient designs, have emerged as a promising strategy to enhance heat transfer performance. By integrating biomimetic honeycomb structures into heat exchangers, you can markedly improve the heat transfer coefficient and system efficiency. Increasing the number of honeycomb layers and applying structural modifications—such as variable cross-sections and fluted geometries—boost performance and compactness. Fin optimization, supported by numerical simulation, helps identify the best geometries for maximum heat transfer. Studies show that biomimetic designs outperform conventional tube-in-tube coolers, especially at low water flow rates. These enhancements lead to substantial performance improvements, ultimately elevating heat pump efficiency through innovative fin optimization strategies rooted in nature-inspired structural modifications. Additionally, the application of sound design techniques can be used to simulate and analyze the acoustic characteristics of these enhanced systems, ensuring both efficiency and operational noise reduction. Moreover, considering cost-effective materials during design can further improve the economic viability of these biomimetic heat exchangers without compromising performance. Incorporating material durability is also essential to ensure long-term operational stability under varying environmental conditions. Furthermore, the use of diverse fin geometries can aid in customizing heat exchangers for specific applications, maximizing their effectiveness across different operational scenarios. To further enhance performance, integrating adaptive control systems can optimize heat transfer processes in real-time based on operational demands.

Integration of Phase Change Materials and Nanofluids

Integrating phase change materials (PCMs) and nanofluids into heat transfer systems offers a powerful way to enhance thermal performance. PCM integration increases latent heat storage capacity, stabilizes temperature fluctuations, and reduces thermal resistance in heat exchangers. Nanofluids, enhanced with nanoparticles, boost heat transfer coefficients by 20–50%, markedly improving heat pump efficiency. By combining nanofluids with shape-stabilized PCMs, you can achieve higher heat transfer rates and better thermal storage. Enhanced thermal conductivity is a key factor in achieving these improvements, allowing for faster and more efficient heat exchange. Key benefits include:

- Increased thermal conductivity for improved heat transfer

- Enhanced heat exchanger performance through PCM integration

- Superior heat transfer enhancement via nanofluid cooling

These advancements lead to more efficient systems, better energy utilization, and optimized thermal management in heat pumps.

Computational Modeling and Simulation for System Enhancement

You can use computational modeling and simulation tools like CFD in ANSYS Fluent to analyze heat transfer processes inside heat pump components with high precision. Sensitivity analysis helps identify critical parameters, enabling you to optimize designs for better efficiency. Implementing these strategies leads to improved system performance and more effective heat transfer solutions.

Numerical Simulation Techniques

Numerical simulation techniques, such as computational fluid dynamics (CFD), play a crucial role in analyzing and optimizing heat transfer within heat exchangers. They allow you to perform detailed heat transfer modeling, flow analysis, and predict heat transfer coefficients accurately. Using methods like finite element analysis and finite volume approaches, you can model complex geometries and evaluate temperature distribution, pressure drops, and structural effects. These simulations support heat exchanger optimization by adjusting design parameters like fin configurations and flow rates to improve system performance. Advanced tools incorporate transient thermal analysis and fluid–solid coupling, providing insights into dynamic behaviors. To guarantee accuracy, CFD validation against experimental data is essential, guiding practical improvements and boosting energy efficiency.

- Precise heat transfer modeling

- Design parameter optimization

- Validation for reliable results

Sensitivity Analysis Insights

Building on the capabilities of computational modeling techniques, sensitivity analysis offers a powerful way to pinpoint which parameters most influence heat transfer efficiency in ground-source heat pump (GSHP) systems. Through numerical simulation, you can identify soil thermal conductivity as the most impactful parameter, profoundly affecting system performance. Sensitivity analysis quantifies how variations in soil properties, grout conductivity, borehole design, and fluid flow influence overall efficiency. Software like FLUENT, utilizing fluid–solid coupling, helps you evaluate these factors systematically. By understanding parameter influence, you can target system optimization efforts effectively, leading to improvements in heat transfer efficiency. This approach empowers you to make informed decisions on borehole design and material choices, ultimately maximizing the performance of your ground-source heat pump system.

Optimization Strategies Implemented

How can computational modeling and simulation drive the enhancement of heat pump systems? By leveraging CFD simulations in ANSYS Fluent, you can analyze heat transfer mechanisms precisely, identifying key areas for heat transfer optimization. Numerical modeling allows you to test various configurations rapidly, improving heat exchanger design and increasing the heat transfer coefficient. Simulation-based optimization predicts outlet temperatures and pressure drops with minimal deviations, guiding system efficiency improvements. Adjusting parameters like flow rate control, thermal conductivity, and U-tube geometry considerably boosts performance.

- Use CFD simulations to explore heat transfer enhancement strategies

- Optimize heat exchanger design through simulation-based approaches

- Employ sensitivity analyses for parameter tuning and efficiency gains

Frequently Asked Questions

How to Increase the Efficiency of Heat Transfer?

To increase heat transfer efficiency, you should focus on improving heat exchanger design. Incorporate spiral fins or double spiral geometries with ideal pitches around 40 mm to boost thermal performance. Embed microencapsulated PCMs to stabilize temperatures and enhance storage. Use nanofluids with innovative tube shapes like elliptical U-tubes or honeycomb structures to considerably raise heat transfer rates. Additionally, optimize borehole and U-tube layouts through simulations for better performance.

How Do You Increase the Efficiency of a Heat Pump?

Think of your heat pump as a finely tuned orchestra; every component must harmonize for peak performance. To boost its efficiency, you can incorporate advanced heat exchangers like spiral fins or microchannels, embed phase change materials to stabilize temperatures, and use nanofluids to reduce thermal resistance. Optimizing flow rates, running simulations, and recovering waste heat all work together to create a symphony of energy savings and superior performance.

What Makes Heat Transfer More Efficient?

To make heat transfer more efficient, you should focus on increasing surface area using designs like spiral fins or honeycomb structures. Incorporate phase change materials (PCMs) to stabilize temperatures and boost energy storage. Use advanced materials such as nanofluids or microchannels to improve thermal conductivity. Additionally, optimize the heat exchanger’s geometry with multi-layer setups or biomimetic shapes, which can markedly enhance heat transfer performance.

What Are the Common Methods to Enhance Heat Transfer of Heat Exchangers?

You might think adding fins or using innovative geometries always boosts heat transfer, but studies show their effectiveness depends on specific conditions. To enhance heat exchanger performance, you can incorporate fins like spiral or double spiral fins with a 40 mm pitch, use honeycomb structures, microchannels, or variable cross-section tubes. Embedding phase change materials, optimizing layer arrangements, and employing nanofluids or biomimetic designs also profoundly improve heat transfer efficiency.

Conclusion

By adopting innovative geometries and advanced materials, you can boost heat transfer efficiency in heat pumps markedly. For instance, microchannel heat exchangers can increase thermal performance by up to 40%, reducing energy consumption and costs. Integrating phase change materials and nanofluids further enhances system effectiveness. With computational modeling guiding design improvements, you’re equipped to create more sustainable, high-performing heat pump systems, helping you contribute to energy efficiency and environmental conservation efforts.