Advanced materials like metal foams, nanomaterials such as graphene, and composites greatly improve thermal conductivity in heat pumps. These innovations speed up heat transfer, boost efficiency, and enhance system durability. Techniques like additive manufacturing create intricate geometries, further optimizing performance. By incorporating eco-friendly, corrosion-resistant materials, you can achieve sustainable and long-lasting solutions. Continue exploring to discover how these cutting-edge materials are transforming heat pump technology for better energy management.

Key Takeaways

- Incorporation of nanomaterials like graphene and carbon nanotubes can boost thermal conductivity by up to 200%, enhancing heat pump efficiency.

- Metal foams and composites increase heat transfer coefficients by up to 125%, improving thermal performance in heat exchangers.

- Additive manufacturing enables complex geometries, such as microchannels, to optimize heat transfer pathways within heat pumps.

- Embedding phase change materials and high-conductivity fillers reduces phase change times and enhances thermal storage capacity.

- Development of eco-friendly, corrosion-resistant composite materials ensures durable, high-conductivity components for long-term operation.

The Role of High-Conductivity Materials in Heat Pump Efficiency

High-conductivity materials play a crucial role in boosting heat pump efficiency by accelerating heat transfer within the system. Using high-conductivity materials like copper and metal foams enhances heat transfer, reducing phase change times and improving overall performance. Incorporating materials with thermal conductivities of 1–3 W/mK in heat exchangers can increase exergy extraction, especially in cooler climates like Stockholm. Conductive scaffolds, such as copper matrices, speed up melting and solidification processes by over 50%, enabling faster thermal cycling. Metal-based heat transfer enhancements substantially boost latent heat transfer capacity—up to 125%—which improves thermal storage. These advanced materials allow the design of compact, high-performance heat exchangers, ultimately increasing heat pump efficiency and optimizing energy systems. Additionally, leveraging trailer music insights can inspire innovative approaches to designing efficient thermal management solutions. Moreover, understanding self-awareness can lead to more innovative and effective material choices by fostering deeper insights into system interactions and performance optimization. Recognizing the importance of energy efficiency ratings assists in selecting materials that maximize system performance and sustainability. Furthermore, selecting materials with verified credibility of suppliers ensures the reliability and longevity of thermal components, which is essential for maintaining system efficiency. Incorporating cost-effective solutions ensures that advancements remain viable within budget constraints, making sustainable options more accessible.

Innovations in Material Engineering for Thermal Enhancement

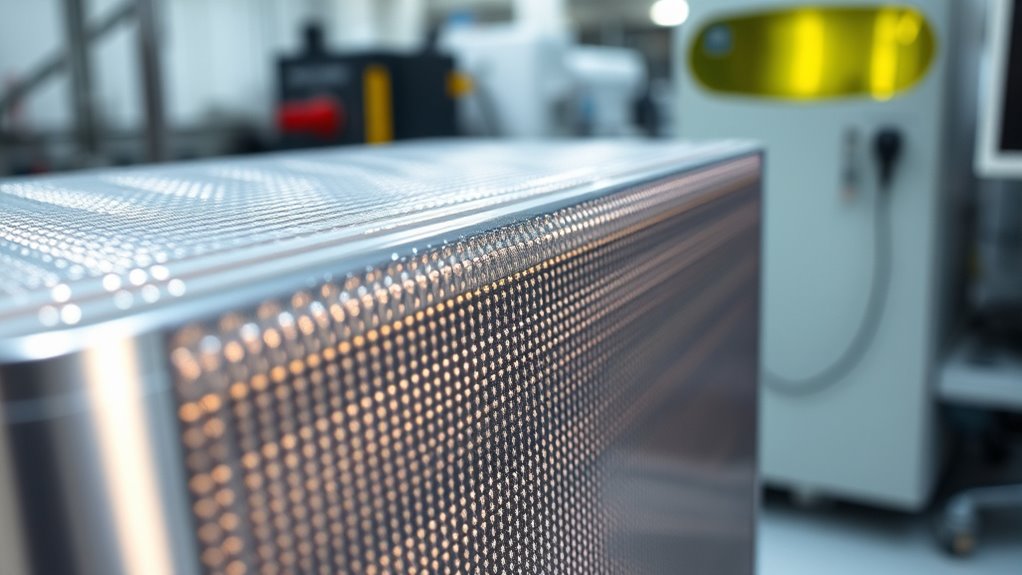

Advancements in material engineering are driving significant improvements in thermal performance for heat pump components. You can now benefit from innovations like metal foams, nanomaterials, and composite materials that boost thermal conductivity. These materials enhance heat exchangers by increasing heat transfer rates and reducing operational times. For example:

- Metal foams and nanomaterials improve heat transfer coefficients by up to 125%, making systems more efficient.

- Additive manufacturing allows for intricate geometries such as microchannels, optimizing heat transfer, and enables customized designs that improve overall system performance.

- Embedding phase change materials enhances thermal management during temperature fluctuations.

- Developing multifunctional composites combines high thermal conductivity with durability, boosting heat pump efficiency.

- Proper maintenance and cleaning of heat exchangers and related components ensure sustained optimal performance in heat pump systems.

- Integrating advanced materials with smart control systems can further enhance energy efficiency and operational stability. Additionally, the development of material interfaces that improve bonding between different components has contributed to increased thermal conductivity and system reliability. Furthermore, ongoing research into thermal interface materials aims to reduce contact resistance and further improve heat transfer efficiency.

These innovations accelerate heat transfer, improve thermal management, and push the boundaries of heat pump performance.

Techniques for Integrating Advanced Materials Into Heat Pump Systems

Integrating advanced materials into heat pump systems requires precise techniques that guarantee ideal thermal performance. Metal matrix composites, nanocomposites, and high-conductivity alloys are incorporated using methods like additive manufacturing and microencapsulation. These techniques enable the creation of complex geometries, such as finned or porous structures, which optimize surface area and reduce thermal resistance. Proper heat exchanger design ensures these materials are seamlessly integrated, enhancing thermal transfer and system efficiency. Additionally, understanding the thermal properties of these materials is crucial for maximizing their effectiveness in heat pump applications. The thermal conductivity of materials plays a significant role in determining the overall system performance, making it essential to select materials with optimal heat transfer characteristics. Exploring advanced manufacturing techniques can further enable the development of highly efficient heat exchangers that leverage these innovative materials. By focusing on thermal transfer enhancement and innovative heat pump materials, you can markedly improve charging and discharging times. Here’s a quick overview:

| Technique | Application | Benefit |

|---|---|---|

| Metal matrix composites | Heat exchangers | Reduce thermal resistance |

| Additive manufacturing | Complex geometries | Improve heat transfer rates |

| Microencapsulation | Thermal transfer enhancement | Protect nanocomposites, boost performance |

Advanced materials such as graphene-enhanced composites can further enhance the durability and efficiency of heat pump systems, ensuring long-term performance under varying operational conditions.

Case Studies Showcasing Material Improvements in Heat Transfer Performance

Numerous case studies reveal how incorporating advanced materials substantially boosts heat transfer performance in heat pump systems. For example, high thermal conductivity materials like copper matrices reduce PCM phase change times by up to 79%, enhancing thermal performance. Metal foams and nanomaterials in heat exchangers increase energy storage capacity by over 125%, enabling faster charging cycles. Metallic structures such as spiral fins accelerate melting processes by approximately 24.5%, optimizing heat transfer. Additionally, numerical models with conductive additives predict phase change durations decrease by over 54%. These improvements demonstrate that advanced materials, including copper and metal foams, markedly elevate heat pump efficiency. Incorporating material design strategies can further optimize thermal management systems for specific applications. Integrating these innovations results in more compact, energy-efficient thermal management systems that outperform traditional designs. Environmental considerations play a crucial role in ensuring sustainable operation and minimizing ecological impact. Furthermore, selecting preppy dog names that match the innovative approach can inspire creative branding for new thermal materials. Proper selection of thermal interface materials also contributes significantly to reducing thermal resistance and improving overall system performance. Additionally, exploring regional support hours for maintenance can enhance operational reliability and reduce downtime in real-world applications.

Future Directions in Material Development for Sustainable Heating Solutions

Building on recent improvements in heat transfer materials, the future of sustainable heating solutions hinges on developing innovative composites that combine high thermal conductivity with environmental friendliness. You’ll see progress in composite materials infused with nanomaterials like graphene or carbon nanotubes, which can boost thermal conductivity by up to 200%, enhancing heat transfer efficiency. Additive manufacturing enables complex geometries that maximize surface area for rapid heat exchange. Focus also shifts toward eco-friendly, corrosion-resistant materials with long-lasting high thermal performance. Integrating phase change materials with conductive scaffolding can improve energy storage and dynamic response. Additionally, advances in material durability are crucial for ensuring long-term performance in demanding environments. Innovations in material design are driving the development of these next-generation heat transfer solutions. Understanding amazing advancements in material science is essential for driving these innovations forward, especially as new composite materials are engineered for better sustainability and performance.

Frequently Asked Questions

Which Material Has Better Thermal Conductivity?

You’re asking which material conducts heat better. Among common options, silver has the highest thermal conductivity at about 429 W/m·K, but it’s expensive. Copper follows closely with around 400 W/m·K, making it a popular choice. However, emerging materials like graphene surpass both, with conductivities over 2000 W/m·K. So, if cost isn’t a concern, graphene offers the best thermal conductivity, but for practical uses, silver or copper are often preferred.

What Materials Maximize Thermal Energy Flow?

So, you want to maximize thermal energy flow, huh? Well, forget about those sluggish materials; go for metals like copper and aluminum—they’re the real superheroes with high conductivities. Add some nanoparticles like graphene or nanotubes for extra punch. Metal foams and embedded metallic structures also boost transfer rates over 125%. In short, selecting high-conductivity metals and advanced composites will make your heat pump perform like a champ.

What Material of the Following Has the Highest Thermal Conductivity?

You’re asking which material has the highest thermal conductivity. Among the options, diamond stands out with an exceptional thermal conductivity exceeding 2000 W/m·K, far surpassing metals like copper, silver, gold, or aluminum. Diamond’s remarkable ability to conduct heat makes it the top choice if maximizing thermal transfer is your goal. Its superior properties mean it can efficiently dissipate heat, although cost and practicality might influence your material selection.

What Is the Best Thermal Conductivity Insulation?

You’re asking about the best thermal conductivity insulation. To maximize heat pump efficiency, look for materials with the lowest thermal conductivity, like aerogels or vacuum insulated panels. Aerogels have the lowest at around 0.013 W/m·K, offering superior insulation but at a higher cost. VIPs are even thinner and more effective. Choose based on your space, budget, and temperature needs for ideal performance.

Conclusion

By embracing advanced materials with superior thermal conductivity, you release the potential to transform heat pump performance. These innovations act as the heartbeat of efficient heating, propelling us toward a sustainable future. Imagine the possibilities as you harness cutting-edge technology—you’re not just upgrading a system; you’re shaping a greener tomorrow. So, seize this opportunity and let these materials be the catalyst that propels your heat pump into a new era of energy efficiency.