Choosing the right refrigerant substantially affects thermal energy transfer by influencing its thermophysical properties like thermal conductivity, specific heat, and boiling point. These properties determine how effectively heat moves during phase change and affect droplet atomization and boiling behavior. Using refrigerants with ideal composition and phase change characteristics can boost heat exchange efficiency while ensuring system safety and environmental compliance. If you explore further, you’ll discover detailed insights on optimizing refrigerant selection for better cooling performance.

Key Takeaways

- Refrigerant thermophysical properties, like thermal conductivity and specific heat, directly influence heat transfer efficiency.

- The refrigerant’s phase change behavior, including boiling point and latent heat, impacts heat exchange effectiveness.

- Composition and droplet atomization affect spray dynamics, droplet size, and overall heat transfer performance.

- Compatibility with system materials and safety features determine refrigerant suitability for optimal energy transfer.

- Regulatory and environmental considerations guide refrigerant selection, affecting system design and long-term thermal performance.

Thermophysical Properties and Their Effect on Heat Transfer Efficiency

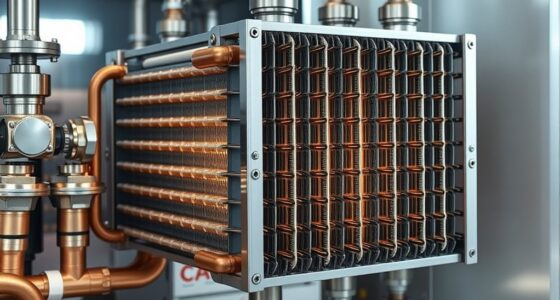

The thermophysical properties of refrigerants play a critical role in determining heat transfer efficiency within a cooling system. High thermal conductivity allows for more effective heat exchange between the refrigerant and the working fluid, boosting overall heat transfer rates. Your choice of refrigerant considerably impacts heat exchanger performance and system efficiency, as properties like specific heat capacity influence how much heat the refrigerant can absorb or release. The heat transfer coefficient depends on these thermophysical characteristics, affecting flow behavior and pressure drops. Additionally, accurate knowledge of refrigerant properties across various temperatures and pressures ensures ideal refrigerant selection, maximizing heat transfer rates and maintaining efficient operation. Utilizing advanced automation in analyzing refrigerant properties can lead to more precise system optimization. Ultimately, understanding these thermophysical properties helps you design systems with better heat transfer performance and improved energy efficiency.

Refrigerant Composition and Its Influence on Droplet Atomization

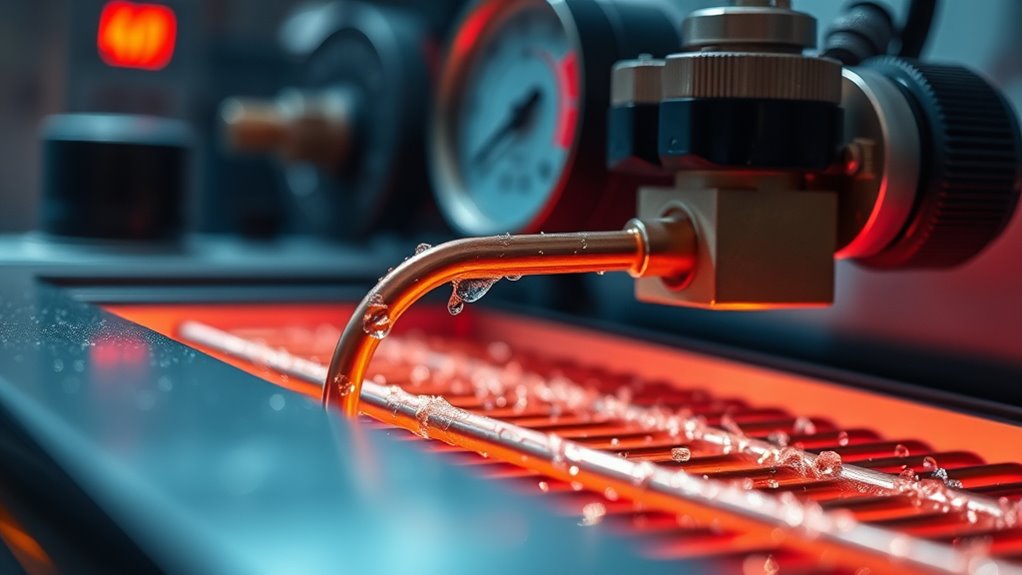

Refrigerant composition considerably influences droplet atomization by altering spray dynamics and droplet formation. When you include high boiling point components like n-butane and i-pentane, you enhance spray cooling by increasing spray droplet velocity and improving spray quality. The refrigerant mixture determines the atomization index, directly impacting heat transfer efficiency. Higher refrigerant pressure and charge lead to more vigorous atomization, creating finer droplets with smaller sizes that promote rapid heat transfer. Additionally, calibration of the system can optimize droplet size distribution and improve overall performance. Proper system maintenance ensures consistent atomization behavior and system reliability. Understanding the tuning laws can help prevent over-atomization and system instability caused by excessive refrigerant charge or pressure. However, too much refrigerant or excessive pressure can cause over-atomization, resulting in coarser spray patterns and system instability. Balancing refrigerant composition is vital to optimize droplet formation, maintain system stability, and maximize heat transfer performance during spray cooling. Incorporating insights from digital literacy can help optimize the integration of innovative refrigerant technologies, ensuring more efficient thermal energy transfer systems. Moreover, considering the cost-effectiveness of refrigerant mixtures can influence the sustainability and economic viability of cooling systems. This delicate interplay underscores the importance of refrigerant mixture design in efficient thermal energy transfer.

Phase Change Dynamics and Heat Exchange Performance

How efficiently heat exchanges during phase change hinges on the refrigerant’s thermophysical properties like latent heat, boiling point, and thermal conductivity. These properties determine the nature of phase change, affecting heat transfer performance. During nucleate boiling, high boiling heat flux occurs as vapor bubbles form and detach rapidly, enhancing heat exchange efficiency. However, excessive vapor film formation can cause a shift to film boiling, drastically reducing heat transfer. The refrigerant’s latent heat influences the amount of energy absorbed during vaporization, impacting system design and performance. Vapor film formation can lead to a significant decline in heat transfer efficiency, emphasizing the importance of selecting refrigerants that promote vigorous boiling while minimizing vapor buildup. Variations in pressure and refrigerant charge affect these dynamics, highlighting the importance of choosing the right thermophysical properties to maximize heat transfer during phase change. Additionally, the compatibility with system components plays a crucial role in maintaining optimal heat exchange performance. Incorporating refrigerants with favorable boiling point characteristics can optimize the phase change process and improve overall system efficiency. Advances in sensor technology also aid in monitoring and controlling phase change behavior to optimize heat transfer efficiency. Proper refrigerant charge levels are essential to sustain desirable boiling behavior and prevent inefficient vapor buildup, ensuring consistent system performance.

Optimization Strategies for Enhanced Thermal Transfer

Optimizing thermal transfer in refrigeration systems involves carefully selecting refrigerants with properties that maximize heat exchange efficiency. Effective refrigerant selection considers thermophysical properties like boiling point and heat capacity, which directly influence heat transfer efficiency. Incorporating refrigerant mixtures with high boiling point components, such as n-butane or i-pentane, enhances heat exchange between natural gas and the refrigerant, boosting thermal system performance. Optimization strategies include simulation-based adjustments of refrigerant composition and process parameters, reducing energy consumption and improving exergy efficiency. Proper refrigerant charge management affects droplet atomization and heat flux, shifting boiling regimes to optimize heat transfer. Developing standardized guidelines for refrigerant components allows tailored process optimization, ensuring maximum heat transfer while maintaining system reliability and efficiency. Additionally, understanding the Louisiana Alimony Laws can be crucial for financial planning during system upgrades or transfers, as it impacts post-divorce financial stability and responsibilities. Incorporating refrigerant thermophysical properties into the design process further enhances system performance by enabling precise control over heat exchange processes. Moreover, considering the changing refrigerant regulations ensures compliance and sustainability in system upgrades. Recognizing the importance of environmental impacts can guide more sustainable refrigerant choices, reducing ecological footprints and promoting eco-friendly practices. Furthermore, utilizing detailed system modeling can help identify potential inefficiencies and optimize overall system performance.

Practical Considerations for Selecting Refrigerants in Cooling Systems

Selecting the right refrigerant involves balancing its thermal properties, compatibility with system materials, and safety considerations to guarantee efficient and reliable cooling. When making refrigerant selection, consider:

- The refrigerant’s heat transfer performance, influenced by properties like heat capacity and boiling point, to optimize energy efficiency. Thermal properties play a crucial role in system performance and should be carefully evaluated.

- Compatibility with system materials and operating conditions, ensuring the refrigerant can handle pressure and temperature ranges without corrosion or failure.

- Environmental impact, favoring low GWP refrigerants such as natural options like ammonia or recent low-GWP HFOs, to reduce ecological footprint.

- Safety considerations, including flammability and toxicity, which influence system design and handling procedures. Balancing these factors ensures safe, effective, and sustainable thermal energy transfer.

Additionally, understanding regulatory compliance and the potential for future restrictions on certain refrigerants is essential for long-term system viability.

Frequently Asked Questions

Why Do We Use Refrigerant to Heat Transfer?

You use refrigerants for heat transfer because they effectively absorb and release large amounts of heat during phase changes. Their properties allow you to transfer thermal energy efficiently across different temperatures, making them ideal for heating and cooling. By cycling through vaporization and condensation, refrigerants help you regulate temperatures smoothly. Choosing the right refrigerant enhances system efficiency, reduces energy use, and ensures safe, environmentally friendly operation.

What Is the Impact of Refrigerants?

Imagine your cooling system as a finely tuned orchestra, where refrigerants are the conductors guiding heat transfer smoothly. The refrigerant’s properties, like boiling point and thermal conductivity, shape this harmony, either amplifying or dampening energy flow. Your choice impacts efficiency, safety, and environmental footprint. Picking the right refrigerant ensures your system performs at its best, balancing performance with sustainability and safety—like a conductor guiding a perfect symphony.

What Is the Choice of Refrigerant in Thermodynamics?

When choosing a refrigerant in thermodynamics, you consider its thermophysical properties like boiling point, heat capacity, and thermal conductivity, which affect heat transfer efficiency. You also evaluate safety factors such as flammability and toxicity, along with environmental impacts like GWP and ODP. Compatibility with system materials and operating conditions is essential, ensuring ideal performance and energy efficiency in your refrigeration or heat pump system.

What Happens When the Refrigerant of a Cooling System Absorbs Thermal Energy?

When your refrigerant absorbs thermal energy, it changes from liquid to vapor, staying at its boiling point. This process allows heat to transfer away from the cooled space. As the refrigerant absorbs heat, its internal energy increases, raising vapor pressure and volume. This cycle keeps the system moving efficiently, helping you maintain the desired temperature while maximizing heat transfer.

Conclusion

Choosing the right refrigerant directly impacts your system’s efficiency, performance, and sustainability. By understanding thermophysical properties, optimizing phase change dynamics, and considering practical factors, you can enhance heat transfer and reduce energy consumption. Focus on refrigerant composition, droplet atomization, and heat exchange processes to maximize results. Ultimately, selecting the best refrigerant isn’t just about compliance; it’s about improving your system’s effectiveness, efficiency, and environmental responsibility—making smarter choices for better cooling performance.