Inverter technology adjusts the compressor’s speed to match your cooling or heating needs, making it more efficient and quieter than traditional fixed-speed compressors. It reduces energy consumption, lowers electricity bills, and offers smoother operation that lasts longer with less maintenance. While inverter systems cost more upfront, their long-term savings and comfort benefits are worth it. To discover detailed differences and which system suits your needs best, keep exploring the key features below.

Key Takeaways

- Inverter compressors adjust their speed based on cooling needs, while traditional compressors operate at fixed speeds.

- Inverter systems consume less energy and offer better long-term cost savings compared to traditional AC compressors.

- They run more quietly and smoothly, reducing noise levels and enhancing user comfort.

- Inverter compressors tend to last longer and require less maintenance due to fewer start-stop cycles.

- Although more expensive initially, inverter systems provide greater efficiency and durability over traditional compressors.

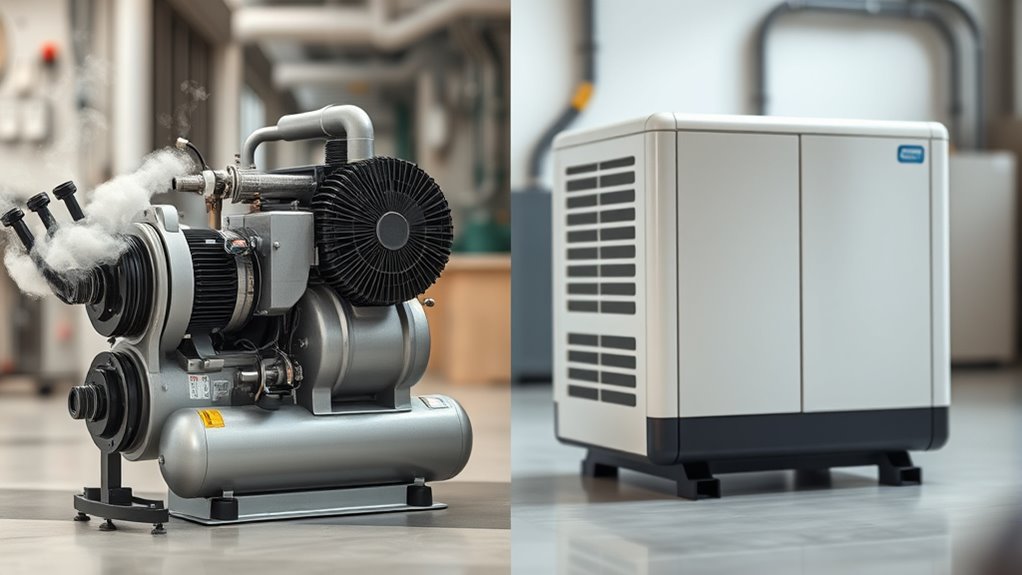

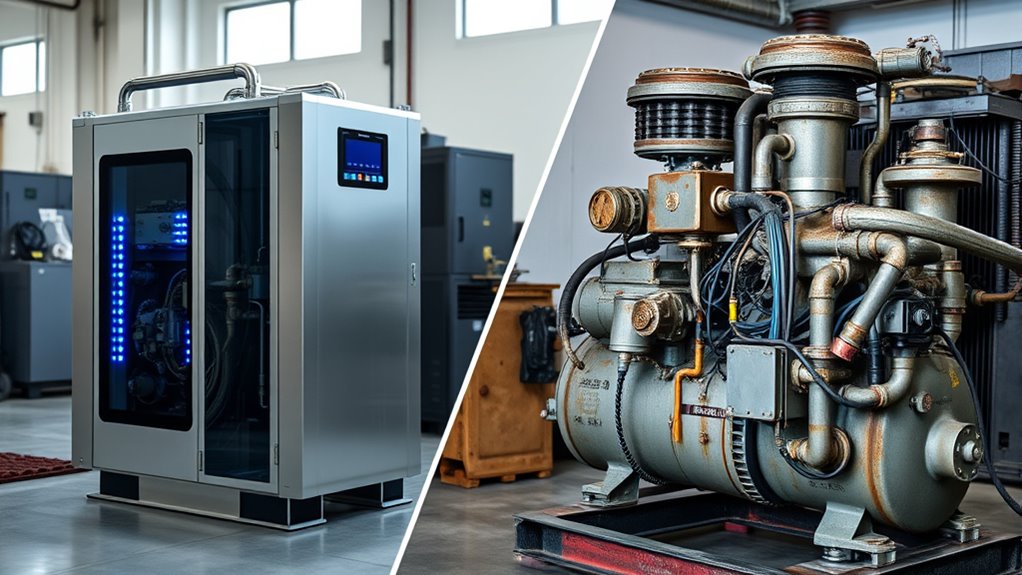

How Inverter Technology Works Compared to Traditional Compressors

While traditional AC compressors run at a fixed speed, inverter technology adjusts the compressor’s power based on cooling or heating needs. Instead of turning on and off repeatedly, a variable speed compressor uses power modulation to match the required temperature more precisely. This means it speeds up or slows down smoothly, maintaining consistent comfort levels. The inverter’s ability to regulate power allows it to operate efficiently, reducing energy waste caused by constant cycles. You benefit from a more stable temperature, quieter operation, and less strain on the system. Power modulation ensures the compressor runs only as hard as necessary, making your air conditioning or heating system more adaptable and responsive to changing conditions. Additionally, the integration of Remote Hackathons has fostered innovation in developing smarter and more efficient inverter systems. Incorporating advanced control algorithms further enhances system responsiveness and energy savings, ensuring optimal performance and reliability.

Energy Consumption and Cost Efficiency

Inverter technology considerably reduces energy consumption compared to traditional AC compressors by adjusting power output to match real-time cooling or heating demands. This results in significant power savings, especially during partial load conditions, since the compressor doesn’t run at full capacity constantly. Over time, these savings can lead to lower electricity bills, making inverters more cost-effective overall. Additionally, best inverter models often incorporate advanced features that enhance efficiency and durability. These models typically include smart control systems that optimize operation based on environmental conditions. Furthermore, the long-term operational savings associated with inverter technology can justify the initial investment for many consumers. However, keep in mind that installation costs for inverter systems tend to be higher upfront due to more advanced components and technology. Despite this initial expense, the long-term energy efficiency benefits often outweigh the costs, providing a better return on investment. If you’re looking for a more energy-efficient solution and are prepared for higher installation costs, inverter technology offers substantial advantages over traditional AC compressors.

Noise Levels and Operating Comfort

Energy-efficient operation often means a quieter environment, and inverter technology contributes considerably to reducing noise levels compared to traditional AC compressors. By minimizing vibrations and improving sound insulation, inverters operate more smoothly, resulting in less disruptive noise. Here are four ways inverter technology enhances your comfort:

- Vibration reduction: Less vibration means quieter operation and less wear on components. Incorporating vibration control techniques can further improve these benefits.

- Enhanced sound insulation: Better soundproofing materials keep noise contained within the unit.

- Smooth speed adjustments: Gradual changes in compressor speed reduce sudden loud noises.

- Lower overall decibel levels: Inverter compressors run at a steadier, quieter noise level throughout operation. Additionally, the use of durable and lightweight woods in construction can also help in reducing vibrations and noise transmission within the unit, further improving comfort. Incorporating sound dampening materials can further enhance noise reduction capabilities. Implementing these noise mitigation strategies leverages advancements in AI security, ensuring more effective and adaptive noise reduction solutions. Together, these features create a more comfortable environment with less noise disturbance.

Longevity and Maintenance Requirements

Because of their advanced design, inverter compressors generally last longer and require less maintenance than traditional AC compressors. In a durability comparison, inverter units tend to have a higher lifespan due to their smoother operation and fewer starting-stopping cycles. This reduces wear and tear, making them more reliable over time. Additionally, their lower maintenance frequency means you won’t need to service them as often, saving you time and costs. Traditional compressors, on the other hand, may experience more frequent breakdowns because of their constant cycling and higher stress levels. Overall, inverter technology offers a more durable solution with less upkeep, giving you peace of mind and a longer-lasting cooling system. Enhanced durability from their design helps improve overall system longevity and performance. Proper system maintenance also plays a vital role in extending the lifespan of both inverter and traditional compressors. Regular inspections and adherence to manufacturer guidelines can further enhance their performance and reliability, especially considering the role of automation in maintenance in optimizing system health. Incorporating preventive measures can further reduce the likelihood of unexpected failures and ensure consistent operation.

Which System Is Better for Different Needs and Budgets

Choosing between inverter technology and traditional AC compressors depends largely on your specific needs and budget. If you want energy efficiency and long-term savings, inverter systems are ideal, especially when paired with a smart thermostat for better control. For smaller budgets or simpler setups, traditional compressors might suffice. Consider these factors:

- Energy savings: Inverter ACs use less power and are better for daily use. Inverter technology offers significant advantages in reducing energy consumption compared to traditional models.

- Refrigerant types: Inverter units often use eco-friendly refrigerants, while traditional models may rely on older types.

- Control options: Smart thermostats work seamlessly with inverter systems, providing customized comfort.

- Initial cost: Traditional systems are generally cheaper upfront but may cost more over time due to higher energy use.

- Maintenance and longevity: Inverter compressors tend to have a longer lifespan and require less frequent repairs, contributing to overall system durability. Proper maintenance can further extend the lifespan of either system, but inverter compressors typically withstand wear better.

Frequently Asked Questions

Do Inverter ACS Have Higher Initial Purchase Prices?

You might notice that inverter ACs have a higher initial purchase price, mainly due to their advanced technology. The cost difference stems from their ability to adjust compressor speed, which improves efficiency. When doing a price comparison, you’ll find that inverter models generally cost more upfront. However, their energy savings can make up for the higher initial investment over time, making them a smart choice in the long run.

Can Inverter Technology Be Integrated Into Existing Traditional Systems?

Thinking about upgrading your AC? While inverter technology offers great efficiency, integrating it into your existing system isn’t always straightforward. You might find that retrofit compatibility varies, and upgrade costs can add up depending on your current setup. Sometimes, a full replacement is more practical than a partial upgrade, especially if your system is quite old. Consulting with a professional can help you weigh the benefits and costs effectively.

How Does Inverter Technology Affect Indoor Air Quality?

Inverter technology improves indoor air quality by maintaining consistent temperatures and reducing humidity, which helps prevent mold and bacteria growth. It also enhances ventilation efficiency by providing smoother operation and better airflow control. As a result, your indoor environment stays fresher and healthier. You’ll notice less dust and allergens circulating, making your space more comfortable. Overall, inverter tech supports cleaner, more breathable indoor air, benefiting your health and well-being.

Are Inverter Compressors More Environmentally Friendly?

Imagine a gentle breeze helping you breathe easier—this is what inverter compressors offer for the environment. They’re more eco-friendly because they use less energy, leading to significant energy savings. By consuming less power, they reduce your device’s climate impact, helping lower greenhouse gas emissions. So, when you choose inverter compressors, you’re making a smarter choice that benefits both your home and the planet.

What Are Common Myths About Inverter ACS?

You might believe inverter ACs are noisy or less reliable, but that’s a myth. Inverter units actually offer better energy efficiency and lower noise levels because they adjust compressor speed to match cooling needs. This means less power consumption and quieter operation. Don’t assume they’re complicated or fragile; inverter ACs are durable and modern, providing consistent comfort while saving energy and reducing noise.

Conclusion

Ultimately, choosing between inverter technology and traditional compressors depends on your needs and budget. Inverter systems may cost more upfront but save you money in the long run with energy efficiency and quieter operation. Traditional compressors might be more budget-friendly, but they can wear out faster and be noisier. Don’t put all your eggs in one basket—consider what matters most to you, and remember, it’s better to be safe than sorry when making your decision.