When designing low-temperature radiators for heat pumps, focus on optimizing insulation, materials, and geometry to maximize heat transfer and efficiency. Use high-conductivity materials like copper or aluminum, incorporate fins or surface enhancements, and plan flow channels carefully for even distribution. Modern designs also consider aesthetics and sustainability, blending performance with style. If you want to explore ways to improve comfort, reduce energy use, and integrate new innovations, you’ll find valuable insights ahead.

Key Takeaways

- Optimize insulation and thermal efficiency to allow effective radiator operation at lower temperatures, reducing energy consumption.

- Use high-conductivity materials like copper or aluminum with surface area enhancements such as fins or intricate patterns.

- Design radiator geometry and flow channels for even heat distribution, minimal pressure drops, and seamless integration with heat pump systems.

- Incorporate corrosion-resistant coatings and sustainable materials to ensure durability and eco-friendly operation.

- Position radiators strategically and customize their layout to maximize heat transfer, occupant comfort, and aesthetic appeal.

Understanding the Principles of Low-Temperature Heating

Understanding the principles of low-temperature heating is essential for designing efficient radiators. When you focus on thermal insulation, you minimize heat loss, ensuring that warm air stays within the space longer. Proper insulation allows the radiator to operate effectively at lower temperatures, reducing energy consumption. Additionally, your choice of aesthetic design plays a vital role; a well-designed radiator blends seamlessly with your interior, providing both form and function. Low-temperature systems require radiators that distribute heat evenly without compromising style. By understanding these principles, you can create a heating solution that is not only energy-efficient but also visually appealing. Incorporating water park features such as water slides and lazy rivers can inspire innovative and flowing radiator designs that enhance both functionality and aesthetics. Ultimately, balancing thermal insulation and aesthetic design helps you optimize comfort while maintaining an attractive environment.

Material Selection for Enhanced Heat Transfer

Choosing the right materials is vital for maximizing heat transfer in low-temperature radiators. You should consider conductive properties to guarantee efficient energy flow, while also addressing corrosion resistance to prolong durability. Additionally, optimizing surface area can considerably boost heat exchange, making your design more effective. Incorporating ergonomic considerations into your material choices can also enhance overall performance by improving ease of installation and maintenance.

Conductive Material Properties

Selecting the right conductive materials is essential for enhancing heat transfer in low-temperature radiators. You should focus on conductive material selection that offers high thermal conductivity to maximize heat flow efficiency. Materials like copper and aluminum are popular choices because of their excellent thermal conductivity, which facilitates thermal conductivity enhancement. When choosing materials, consider their ability to transfer heat quickly and uniformly, reducing temperature gradients. The material’s density and specific heat capacity also influence performance, so balancing these properties can improve overall efficiency. Avoid materials with poor thermal conductivity, as they hinder heat transfer. Additionally, understanding thermal conductivity mechanisms helps in choosing materials that optimize heat transfer rates. By selecting ideal conductive materials, you ensure your radiator design delivers maximum heat transfer with minimal energy loss, ultimately boosting the performance of your heat pump system.

Corrosion Resistance Strategies

To guarantee your low-temperature radiator maintains peak heat transfer performance, implementing corrosion resistance strategies is vital. You should focus on corrosion prevention by selecting materials resistant to rust and degradation, such as stainless steel or coated metals. Coating techniques play an essential role; applying protective layers like epoxy, ceramic, or polymer coatings can effectively shield the radiator from moisture and corrosive elements. These coatings not only prevent corrosion but also enhance durability and longevity. Regular maintenance and inspections help identify early signs of corrosion, allowing timely intervention. By combining smart material choices with advanced coating techniques, you ensure your radiator remains efficient and reliable over its lifespan, minimizing downtime and repair costs. This strategy optimizes heat transfer and secures long-term operational performance. Incorporating eco-friendly materials can further reduce environmental impact and support sustainable heating systems.

Surface Area Optimization

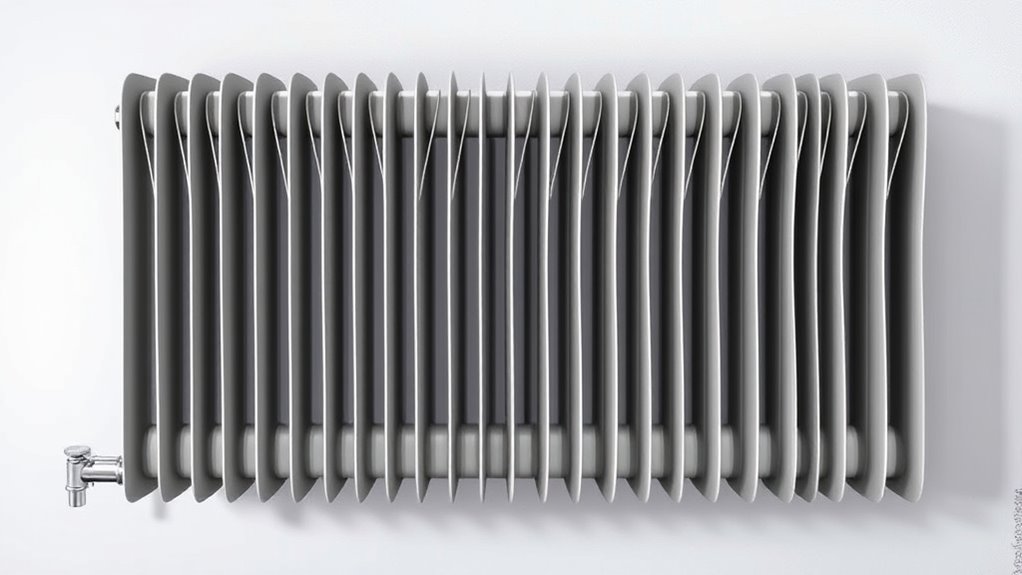

Maximizing surface area is key to boosting heat transfer efficiency in low-temperature radiators. By increasing the surface, you improve heat exchange with the surrounding environment. To achieve this, consider materials that can be shaped into intricate patterns or fins without compromising radiator aesthetics. Enhanced designs not only improve performance but also blend seamlessly with your space’s decor. When selecting materials, prioritize those with high thermal conductivity, like copper or aluminum, to maximize heat transfer. Installation techniques also matter; proper placement and secure mounting of expanded surfaces ensure consistent heat distribution. Additionally, understanding the Pimple Patch technology can inspire innovative surface designs that promote better contact and heat dissipation. Balancing aesthetic appeal with functional design helps create radiators that are both efficient and visually appealing. Focus on optimizing surface area through thoughtful material choices and installation methods to elevate your heat pump system’s performance.

Designing Radiator Geometry for Optimal Performance

To improve your radiator’s performance, focus on maximizing surface area to enhance heat dissipation. You should also optimize flow paths to guarantee efficient coolant movement, reducing temperature gradients. Additionally, designing for better heat transfer involves balancing these factors to achieve the best overall efficiency. Incorporating comfort solutions like high-quality materials can further support effective heat management and user comfort.

Maximizing Surface Area

When designing radiators for low-temperature applications, increasing the surface area directly enhances heat dissipation efficiency. Larger surfaces allow more heat to transfer to the surrounding air, improving overall performance. To maximize surface area effectively, consider shaping the radiator with fins or multiple panels that fit your space and aesthetic goals. Remember, radiator aesthetics matter—you want a design that complements your environment without sacrificing function. Proper installation techniques also play a vital role; ensure the radiator is positioned for ideal airflow and easy maintenance. Here are some key strategies:

- Use extended fins or ribbed surfaces to boost area

- Opt for modular designs that can be expanded

- Incorporate sleek, space-efficient geometries

- Prioritize secure, accessible mounting for maintenance

Additionally, selecting appropriate materials that conduct heat efficiently can significantly improve the radiator’s overall performance.

Optimizing Flow Paths

Designing radiator geometry to optimize flow paths guarantees that heat transfer occurs efficiently throughout the system. Focus on flow channel design to ensure smooth movement of the heat transfer fluid, minimizing pressure drops and turbulence that can hinder performance. Your piping layout should promote even flow distribution, avoiding sharp bends or constrictions that create flow restrictions. A well-planned layout reduces energy consumption and ensures consistent heat delivery. Consider the placement of inlet and outlet connections to facilitate balanced circulation. Additionally, incorporating vertical storage solutions can help manage flow and improve system efficiency. By carefully designing flow channels and piping routes, you improve system efficiency and reliability. This strategic approach helps prevent hot spots and ensures that the low-temperature radiator performs optimally across varying operational conditions.

Enhancing Heat Transfer

Have you ever wondered how the shape and size of a radiator influence its ability to transfer heat effectively? The geometry directly impacts heat transfer efficiency, aesthetic appeal, and installation costs. To enhance performance, consider optimizing fin design, surface area, and flow channels. These adjustments improve heat exchange and can make your radiator more visually appealing. Incorporate larger surface areas or intricate fin patterns to boost heat transfer while maintaining a sleek look. Keep in mind, a more complex design might raise costs, so a thorough cost analysis helps balance performance and budget. Using the right geometry ensures your low-temperature radiator operates efficiently, looks good, and remains cost-effective over its lifespan. Proper design transforms basic radiators into high-performance, attractive heat exchangers. Additionally, understanding personal development principles can help engineers and designers stay motivated and innovative throughout the project.

Integration With Modern Heat Pump Technologies

Integrating low-temperature radiators with modern heat pump systems offers a promising pathway to enhance overall energy efficiency. When designing these radiators, consider radiator aesthetics to guarantee they blend seamlessly with contemporary interiors, encouraging adoption. Modern heat pumps operate efficiently at lower water temperatures, making low-temperature radiators a natural fit. To make integration feasible, focus on reducing manufacturing costs without compromising performance or aesthetics. Streamlining production processes and selecting cost-effective materials can help keep expenses manageable. This integration not only improves system efficiency but also supports sleek, discreet radiator designs that appeal to homeowners. By balancing aesthetics, cost, and compatibility, you enable a smoother transition to energy-efficient heating solutions that leverage the full potential of modern heat pump technology. Additionally, understanding hackathon opportunities can facilitate collaboration with innovators and experts to develop cost-effective and aesthetically pleasing radiator solutions.

Ensuring Uniform Heat Distribution and Comfort

To maximize the benefits of low-temperature radiators within modern heat pump systems, ensuring uniform heat distribution is key to maintaining consistent comfort throughout a space. Proper placement and thoughtful installation techniques help prevent cold spots and hot zones. Focus on selecting radiators with appealing radiator aesthetics that blend seamlessly into your interior design. Consider the following to optimize comfort:

Maximize comfort with proper radiator placement, design, and installation to ensure even heat distribution throughout your space.

- Position radiators near cold spots or exterior walls for even warmth

- Use adjustable thermostats for precise temperature control

- Incorporate proper pipe layout to promote even heat flow

- Choose installation techniques that minimize air gaps and uneven heat spread

Minimizing Thermal Losses and Improving Efficiency

Minimizing thermal losses is essential for maximizing the efficiency of low-temperature radiators. Using ultra thin panels helps reduce heat conduction and radiation losses, ensuring more heat transfers into the room. Incorporate high-quality insulation within the radiator structure to prevent heat escape through the back and sides. Additionally, decorative covers can serve dual purposes: enhancing aesthetics while acting as a barrier against heat loss, especially if made from insulating materials. Proper sealing around joints and connections prevents drafts that can undermine efficiency. Regular maintenance, such as cleaning surfaces and checking for leaks, also plays a key role. By focusing on these strategies, you can markedly improve the performance of your radiator system, ensuring you get the most heat output with minimal energy waste.

Advances in Low-Temperature Radiator Manufacturing

Recent advances in low-temperature radiator manufacturing have revolutionized how these systems are produced, resulting in more efficient, cost-effective, and durable solutions. Innovations like specialized manufacturing techniques enable precision and scalability, reducing production costs and improving quality. An innovative coating enhances corrosion resistance and thermal transfer efficiency, extending radiator lifespan. These developments allow for lightweight designs without sacrificing strength, making installation easier and more flexible. Additionally, modern manufacturing methods support customization, ensuring radiators meet specific heat pump requirements. Overall, these breakthroughs in manufacturing techniques and coatings drive the industry toward more sustainable and reliable low-temperature radiators, helping you maximize heat pump performance while reducing long-term maintenance.

Environmental and Sustainability Considerations

How do low-temperature radiators align with environmental and sustainability goals? They do so by utilizing recyclable materials, reducing waste and promoting circular economy principles. Choosing recyclable components means your radiators can be repurposed or properly disposed of at the end of their lifespan, minimizing environmental impact. Additionally, sourcing materials from renewable sources helps decrease reliance on finite resources, lowering carbon footprints. Incorporating sustainable materials supports eco-friendly manufacturing practices and encourages responsible consumption. These choices not only contribute to reducing greenhouse gas emissions but also enhance the overall sustainability of heat pump systems. By prioritizing recyclable materials and renewable sourcing, you ensure your radiator design aligns with global efforts to protect the environment and promote long-term ecological balance.

Future Trends in Radiator Design for Heat Pump Compatibility

As heat pump technology continues to advance, radiator designs are evolving to become more efficient and better suited for integration with these systems. Future trends focus on incorporating smart materials that adapt to changing conditions, enhancing thermal performance. Aesthetic design also plays a critical role, making radiators more visually appealing and seamlessly fitting into modern interiors. You’ll see innovations like lightweight, flexible panels that maximize heat transfer while maintaining style. Additionally, smart materials enable self-regulating features, reducing energy consumption. The shift toward customizable forms allows for tailored fitting in diverse spaces. These trends aim to optimize efficiency, user comfort, and visual harmony, ensuring radiators meet the demands of next-generation heat pump systems.

- Integration of adaptive smart materials

- Sleek, minimalist aesthetic designs

- Modular, customizable radiator forms

- Energy-efficient, self-regulating features

Frequently Asked Questions

How Do Low-Temperature Radiators Impact Overall Energy Savings?

Low-temperature radiators improve your home’s thermal efficiency by operating at lower water temperatures, which reduces heat loss. This leads to better energy conservation because your heat pump doesn’t have to work as hard, saving energy overall. By using these radiators, you can cut your energy bills and lessen your carbon footprint, making your heating system more sustainable and cost-effective in the long run.

What Are the Cost Implications of Advanced Radiator Materials?

Think of advanced radiator materials as the strong, resilient armor for your heat system. They often feature higher material durability, meaning they last longer and perform better. However, this strength comes at a cost—production costs tend to be higher due to specialized manufacturing processes. While you might invest more initially, the durability and efficiency can save you money in the long run, balancing out the upfront expenses.

How Can Aesthetic Design Be Integrated Without Compromising Performance?

You can achieve aesthetic integration by selecting sleek, modern radiator designs that blend seamlessly with your space. Prioritize visual appeal by using finishes and colors that complement your decor. Incorporate innovative shapes and minimalistic styles to enhance appearance without sacrificing performance. Custom panels or concealed installations also help maintain functionality while guaranteeing the radiators contribute positively to your room’s aesthetic. This approach ensures both form and function work harmoniously.

Are There Specific Regulations Influencing Low-Temperature Radiator Manufacturing?

You should be aware that specific regulations influence low-temperature radiator manufacturing. Regulatory standards set safety, efficiency, and environmental requirements, so you must guarantee your products meet these guidelines. Manufacturing compliance involves adhering to these standards throughout production. Staying informed about evolving regulations helps you avoid legal issues and market restrictions, ensuring your radiators are both safe and efficient, ultimately supporting your business’s success in a competitive industry.

How Do Low-Temperature Radiators Perform in Extreme Climate Conditions?

In extreme climate conditions, low-temperature radiators perform better when they have good thermal insulation, keeping heat inside efficiently. You’ll also want to verify they have strong corrosion resistance to withstand harsh weather. Proper insulation prevents heat loss, while corrosion-resistant materials extend the radiator’s lifespan, even in freezing or humid environments. This combination helps your heat pump operate efficiently and reliably, regardless of severe outdoor temperatures.

Conclusion

Think of low-temperature radiators as the gentle rivers flowing through a landscape, softly warming every corner without turbulence. By understanding the principles, selecting the right materials, and embracing innovative designs, you create a harmonious system that seamlessly integrates with heat pumps. This eco-friendly river brings comfort and efficiency, transforming your home into a warm haven. Embrace these advancements to guarantee your radiant flow sustains both comfort and sustainability for years to come.