In a heat pump system, the compressor is the key component that pushes refrigerant through the cycle by increasing its pressure and temperature. This allows heat to transfer from one area to another, providing both heating and cooling. Different types of compressors—like scroll, rotary, or reciprocating—work efficiently under various conditions. Understanding how they compress refrigerant and impact system performance can help you optimize your heat pump’s efficiency and reliability as you explore further details.

Key Takeaways

- Compressors circulate refrigerant by increasing its pressure and temperature to enable efficient heat transfer.

- They compress refrigerant vapor using mechanisms like pistons, scrolls, or rotary parts.

- The compressor transforms low-pressure, low-temperature refrigerant gas into a high-pressure, high-temperature state.

- Proper compressor operation maintains system efficiency, reliability, and performance across varying conditions.

- Different compressor types (scroll, rotary, reciprocating) offer unique advantages in noise, efficiency, and cold weather handling.

The Role of the Compressor in a Heat Pump

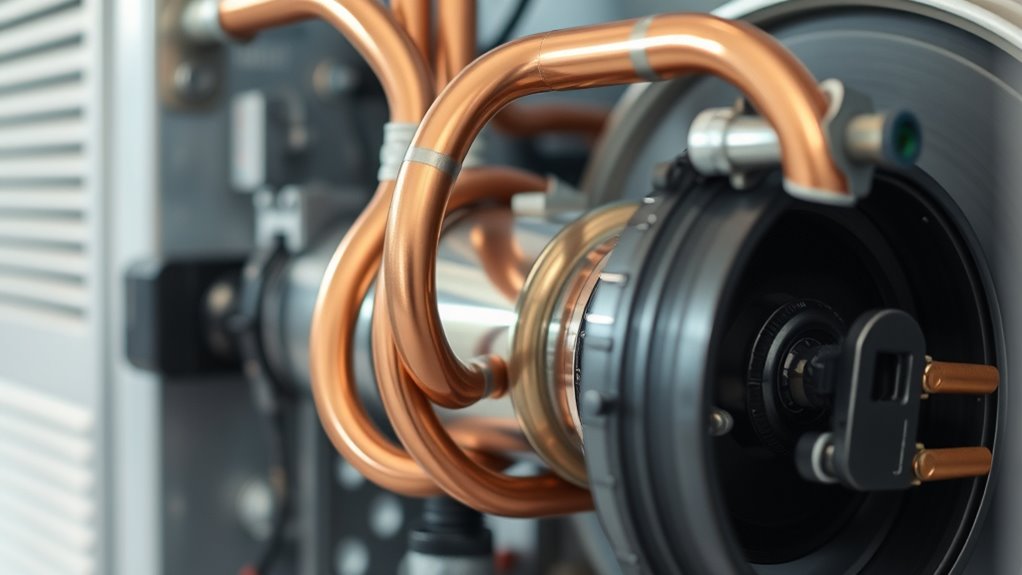

The compressor in a heat pump plays a crucial role by pressurizing the refrigerant to raise its temperature, which is essential for efficient heat transfer. As the compressor operates, it circulates refrigerant through the system, moving it between indoor and outdoor coils. It increases the refrigerant’s pressure from low to high, enabling phase changes necessary for heating or cooling. This pressure boost allows heat to be transferred effectively, whether you’re warming or cooling your space. The compressor’s efficiency directly impacts the overall performance and energy consumption of your heat pump. Usually driven by an electric motor, it can be of various types, such as rotary or scroll, which influence noise and vibration. Without the compressor, the heat pump couldn’t perform its vital heating and cooling functions. Additionally, advancements in AI security are being applied to optimize compressor controls and detect faults, enhancing reliability and energy efficiency. Proper maintenance of the compressor is vital to prevent breakdowns and ensure long-term system performance. Understanding the compressor types and their specific functions can help in selecting the most suitable system for your needs. Recognizing the importance of remote work flexibility can also be applied to maintaining proper system operation and scheduling for optimal efficiency. Moreover, the tax implications of heat pump systems can influence long-term investment decisions.

Types of Compressors Used in Heat Pumps

Different compressor types, like rotary, scroll, reciprocating, and screw, each offer distinct performance and noise characteristics. Your choice impacts system efficiency, vibration, and how well it handles cold weather. Understanding these differences helps you select the right compressor for your heat pump. Additionally, advancements in sound design tools, such as sound libraries, enable engineers to simulate and optimize compressor noise profiles for quieter operation. Recognizing the importance of compressor efficiency can lead to better energy savings and system longevity. Furthermore, selecting a compressor with reliable performance ensures the durability and consistent operation of your heat pump system. Incorporating vibration reduction technologies can further enhance system longevity and reduce operational noise, making the system more user-friendly.

Compressor Types Overview

Have you ever wondered which types of compressors power heat pump systems? The main compressor types include scroll and rotary compressors. Scroll compressors use two interlocking spirals—one fixed and one rotating—to compress refrigerant, offering about 50% less load and quieter operation than piston compressors. They’re ideal for larger units because they’re expandable, deliver high efficiency, and produce low vibration. Additionally, their low vibration contributes to quieter operation and longer lifespan. The compact design of rotary compressors makes them well-suited for smaller heat pump models due to their simplicity and space-saving features. Rotary compressors, on the other hand, have a rotating mechanism with fewer parts, making them simpler, more cost-effective, and easier to maintain. They’re well-suited for smaller heat pump models due to their compact design. The choice between these compressor types considerably affects your heat pump’s performance, noise levels, vibration, and lifespan, making it essential to select the right one for your needs. Additionally, vetted options ensure reliable and efficient operation, which is crucial for long-term durability. Proper installation standards play a vital role in maintaining compressor efficiency and safety over time. For optimal results, selecting a compressor with appropriate specifications is critical to match your heat pump’s size and usage requirements.

Performance and Noise Levels

When choosing a compressor for your heat pump, performance and noise levels are key factors to contemplate. Scroll compressors operate at about 50% less load and produce less noise than rotary compressors. They’re also more expandable and have low vibration, further reducing noise levels. Rotary compressors, with fewer moving parts, are cost-effective but tend to generate higher noise levels and slightly lower compressor efficiency. Your choice impacts overall system performance and comfort. Additionally, understanding compressor types helps in selecting the most suitable option for specific needs. Proper maintenance and selecting the right compressor can also enhance the noise reduction of your heat pump system. Selecting a compressor with energy-efficient features can further improve system performance and reduce operating noise over time. For optimal results, choosing a compressor with advanced technology can help balance efficiency and noise levels effectively. Incorporating sound insulation measures can also significantly decrease operational noise, ensuring a quieter environment.

How a Compressor Compresses Refrigerant

You can think of a compressor as the heart of your heat pump, where it mechanically squeezes refrigerant to increase its pressure and temperature. This process makes the refrigerant ready to transfer heat efficiently in the condenser coil. The way the compressor compresses refrigerant directly impacts the system’s overall performance and energy use. Understanding industry trends helps in selecting the right compressor for optimal efficiency. Additionally, the type of headphone jack used can influence compatibility with various devices and affect user convenience. Proper maintenance and regular system evaluations are essential to mitigate potential operational disruptions and ensure consistent performance. Moreover, the design and efficiency of compressors are often influenced by advances in air conditioning technology, which aim to improve energy savings and system reliability.

Compression Process Mechanics

A compressor in a heat pump uses mechanical work to reduce the volume of refrigerant vapor, which in turn increases its pressure and temperature. Inside, the compressor employs pistons, scrolls, or rotary mechanisms to compress the refrigerant as it enters. This process transforms low-pressure, low-temperature refrigerant gas into a high-pressure, high-temperature state. As the refrigerant is compressed, its pressure rises considerably—often from around 30 psi to over 200 psi—depending on the system. This increase in pressure is essential for the refrigerant to release heat effectively later in the cycle. The compressor’s ability to efficiently compress refrigerant directly impacts the heat pump’s performance and energy use, making its mechanics indispensable to the overall system operation. Proper cybersecurity measures can help prevent system malfunctions or cyberattacks that could disrupt heat pump operations. Self Watering Plant Pots utilize similar principles of maintaining optimal conditions through controlled water delivery, which highlights the importance of system efficiency in various applications. Additionally, the design of compressors often incorporates reliability features to withstand continuous operation and environmental stresses. Implementing maintenance practices can further extend the lifespan and performance of the compressor, ensuring consistent operation.

Impact on System Efficiency

How effectively a compressor compresses refrigerant directly influences the overall efficiency of a heat pump system. When your compressor efficiently increases refrigerant pressure and temperature, it enables better heat transfer, reducing energy waste. The type of compressor, such as scroll or rotary, affects the compression ratio, impacting both system efficiency and energy consumption. Higher compression ratios can improve performance at low outdoor temperatures, but they may also increase energy use and stress on the system. Efficient compression quickly reduces refrigerant volume, allowing your heat pump to cycle smoothly and maintain ideal heating or cooling. If the compressor operates effectively, your system uses less energy and maintains better performance, making it more reliable and cost-effective over time.

The Refrigeration Cycle: Compression and Heat Transfer

The refrigeration cycle relies on the compressor to initiate the process by compressing low-pressure refrigerant vapor, which raises its pressure and temperature. This compression reduces the refrigerant’s volume while boosting its heat transfer capability, making it ready to release heat in the condenser. As the refrigerant becomes high-pressure and high-temperature, it flows into the condenser coil, where it releases heat to warm your space or water. This cycle ensures continuous heat absorption and rejection essential for efficiency. The table below highlights how compression transforms refrigerant properties:

| State | Before Compression | After Compression |

|---|---|---|

| Refrigerant Volume | High | Low |

| Pressure & Temperature | Low | High |

| Heat Transfer | Prepares for heat release | Facilitates heat transfer |

| Cycle Continuity | Maintained by compression | Maintained by the process |

How Compressors Impact Heat Pump Efficiency

Compressors play a crucial role in determining your heat pump’s efficiency by directly influencing the refrigerant pressure and temperature. When your compressor operates efficiently, it increases refrigerant pressure effectively, enabling better heat transfer. The type and design of your compressor, like scroll or rotary, impact the system’s energy consumption and noise levels. High-quality compressors with lower compression ratios perform better, especially at low outdoor temperatures, boosting overall efficiency. Proper sizing guarantees ideal pressure and refrigerant flow, reducing energy loss and enhancing performance. Additionally, advanced compressors with variable speed technology adjust their output in real-time, markedly improving energy efficiency and responsiveness. By selecting a well-designed, efficient compressor, you ensure your heat pump maximizes heat transfer while minimizing energy use.

Factors Affecting Compressor Performance in Cold Weather

In cold weather, outdoor temperatures drop markedly, which directly impacts compressor performance in heat pump systems. When this happens, your refrigerant struggles to evaporate efficiently, lowering overall performance. Higher compression ratios are needed to generate enough heat, but this increases wear on the compressor and boosts energy consumption. Cold ambient conditions can also lead to reduced refrigerant circulation, impairing compressor operation and decreasing efficiency. To combat these issues, you should consider:

Cold weather hampers compressor efficiency and refrigerant flow in heat pumps.

- Using specialized compressor types like inverter-driven models that adapt to cold conditions.

- Increasing discharge pressure to improve refrigerant flow.

- Designing systems that optimize refrigerant flow and manage compression ratios effectively.

These strategies help maintain compressor performance during winter, ensuring your heat pump keeps working efficiently.

Maintenance and Troubleshooting of Heat Pump Compressors

Maintaining your heat pump’s compressor is essential for reliable performance and energy efficiency. Regularly inspect the compressor for overheating, unusual noises, or vibrations, as these signs may indicate problems needing professional repair. Check that refrigerant levels are adequate; low refrigerant can cause the compressor to work harder or fail prematurely. Periodically replace faulty contactors and capacitors, since defective electrical components can hinder proper compressor operation. Keep the outdoor unit free of debris, dirt, and obstructions to ensure proper airflow and reduce strain on the compressor. Scheduling annual professional maintenance helps verify electrical connections, monitor compressor performance, and catch potential issues early. Proper maintenance not only prolongs your compressor’s lifespan but also keeps your heat pump running efficiently year-round.

Advances in Compressor Technology for Improved Performance

Recent innovations in compressor technology are transforming heat pump performance by improving efficiency and reducing noise. You’ll find that modern systems increasingly use:

Recent compressor innovations boost heat pump efficiency and significantly reduce noise levels.

- Variable-speed compressors that adjust capacity on demand, saving energy and maintaining consistent comfort.

- Scroll compressors which cut vibration by about 50%, resulting in quieter operation and longer-lasting components.

- Inverter-driven compressors that continuously modulate speed, optimizing performance across various outdoor temperatures.

These advancements enable your heat pump to operate effectively even in cold climates, reducing energy consumption while maintaining heating capacity. Dual-stage designs further enhance seasonal efficiency and temperature control. By adopting these technologies, your heat pump becomes more reliable, quieter, and energy-efficient, providing superior performance year-round.

Choosing the Right Compressor for Your Heat Pump System

Choosing the right compressor for your heat pump system depends on several factors, including climate, budget, and performance needs. A scroll compressor is ideal if you prioritize quiet operation and energy efficiency, thanks to its lower noise, vibration, and expandable capacity, making it suitable for variable loads. On the other hand, rotary compressors are more cost-effective, have fewer moving parts, and are easier to maintain, which benefits budget-conscious installations. Your climate influences compressor selection too; for cold weather, high-efficiency models like scroll compressors perform better at lower outdoor temperatures. Ultimately, selecting the right compressor enhances heat pump efficiency, ensuring reliable heating and cooling while aligning with your budget and noise preferences. Proper compressor choice optimizes system performance across different conditions.

Frequently Asked Questions

How Does a Compressor Work on a Heat Pump?

You might wonder how a compressor works in a heat pump. It pressurizes the refrigerant, turning it into a high-pressure, high-temperature gas. This process involves compressing the low-pressure gas from the evaporator, which helps transfer heat efficiently. Different compressor types exist, but all mechanically compress refrigerant within sealed chambers. Your heat pump relies on this compression to keep your home warm in winter and cool in summer.

What Happens When a Heat Pump Compressor Goes Bad?

Imagine your heat pump’s compressor unexpectedly quits, like a knight losing his sword. When it goes bad, you’ll notice strange noises, like rattling or squealing, and your system won’t heat or cool properly. You might see frequent breaker trips or overheating, leading to system shutdowns. Over time, a failing compressor boosts energy bills and could mean costly repairs or a full replacement, so don’t ignore these warning signs.

Does a Heat Pump Compressor Run All the Time?

No, a heat pump compressor doesn’t run all the time. It cycles on and off based on your home’s heating or cooling needs. When the desired temperature is reached, the compressor turns off to save energy. In mild weather, it runs intermittently. During colder weather, it may run more frequently or continuously if it struggles to extract enough heat. Modern systems with inverter technology adjust operation for efficiency.

How Much Does a New Compressor for a Heat Pump Cost?

Think of replacing your heat pump compressor like swapping out a worn-out engine in a car—costs can vary. You’ll likely spend between $1,200 and $2,500 for parts, with labor adding another $300 to $800. High-efficiency models can cost over $3,000. Your total depends on whether you replace just the compressor or the entire outdoor unit, and professional installation is a must.

Conclusion

Understanding how compressors work in heat pumps helps you appreciate their essential role in efficient heating and cooling. For instance, choosing the right compressor can make a difference during cold snaps, ensuring your system keeps running smoothly. Regular maintenance, especially in harsh weather, extends your heat pump’s lifespan and maintains performance. By staying informed about compressor technology and performance factors, you can optimize your system’s efficiency and comfort all year round.