To prevent frost buildup on your air source heat pump, you can choose from several defrost strategies. These include temperature-based controls that turn on defrost mode when needed, time-triggered cycles at set intervals, and reverse cycle methods that melt frost using the refrigeration process. Advanced systems use sensors and smart technology to optimize defrosting based on real-time conditions. If you want to understand how each method works and which is best for you, keep exploring further.

Key Takeaways

- Air source heat pumps use various defrost modes, including sensor-based, time-triggered, and reverse cycle methods, to prevent frost buildup.

- Temperature-based control activates defrost when outdoor coil temperatures fall below a set point, conserving energy.

- Time-triggered cycles operate at fixed intervals, regardless of actual frost conditions, which can lead to inefficiency.

- Reverse cycle defrost uses the refrigerant system to melt frost, reducing energy consumption compared to traditional methods.

- Advanced sensors and smart algorithms enable adaptive defrosting, optimizing performance and minimizing unnecessary defrost cycles.

Types of Defrost Modes in Air Source Heat Pumps

Air source heat pumps use different defrost modes to prevent ice buildup on the outdoor coil, ensuring efficient operation in cold weather. These modes are designed to combat frost accumulation that can hinder heat transfer, reducing energy efficiency. One common method is temperature-based defrost, which triggers when frost reaches a certain level, but this isn’t the focus here. Instead, the modes actively detect frost presence through sensors or system signals, initiating defrost cycles only when necessary. This approach minimizes energy consumption and maintains ideal performance. By effectively managing frost accumulation, these defrost modes help keep your heat pump running efficiently, saving energy and preventing unnecessary wear on components. Proper defrost operation is key to sustaining energy efficiency during winter months. Additionally, some systems incorporate automatic sensor detection to optimize defrost timing and further improve efficiency.

Temperature-Based Defrost Control

Temperature-based defrost control relies on measuring the outdoor coil’s temperature to determine when defrosting is necessary. When frost accumulation causes the coil’s temperature to drop below a set point, the system triggers a defrost cycle. This method helps maintain energy efficiency by preventing unnecessary defrosts, which can waste energy. By responding directly to the outdoor coil’s temperature, it minimizes frost buildup without relying on time-based schedules that might over- or under-defrost. This targeted approach reduces frost accumulation, keeps the heat pump operating smoothly, and conserves energy. You benefit from improved system performance during cold weather, as the control adapts to actual conditions rather than fixed timing, ensuring the heat pump works efficiently and reduces energy costs. Additionally, implementing AI safety measures can help monitor and optimize the operation of such control systems, ensuring reliable performance in various environmental conditions.

Time-Triggered Defrost Cycles

Time-triggered defrost cycles activate the heat pump’s defrost mode at predetermined intervals, regardless of actual frost buildup. This approach simplifies operation but can sometimes lead to unnecessary defrosting, especially during low snow accumulation periods. Snow accumulation on the outdoor coil varies with weather conditions, and ambient air variability influences frost formation. When the outdoor temperature fluctuates, this can cause the heat pump to cycle into defrost mode unnecessarily, wasting energy. Time-triggered cycles are designed to prevent frost buildup by periodically defrosting, but they don’t respond directly to real-time frost conditions. As a result, they may be less efficient during periods of minimal frost, but they ensure consistent defrosting in environments with unpredictable snow accumulation or changing ambient air conditions. Additionally, ambient air variability can significantly impact the effectiveness of these cycles, as changing conditions may either trigger unnecessary defrosts or fail to address frost buildup in time.

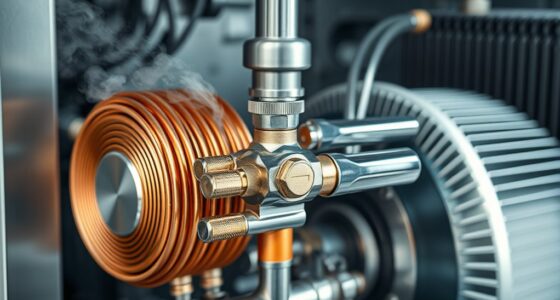

Reverse Cycle Defrost Method

The reverse cycle defrost method utilizes the heat pump’s refrigeration cycle to melt frost on the outdoor coil, eliminating the need for separate defrost heaters or timers. This approach enhances defrost efficiency by reversing the refrigerant flow, causing the outdoor coil to heat up temporarily. As a result, frost melts quickly, reducing energy consumption compared to traditional methods. Additionally, this method benefits from the variety of materials used in heat pump components, which can influence overall system performance and durability.

Advanced Sensors and Smart Defrost Technology

Building on the efficiency of the reverse cycle defrost method, modern heat pumps now incorporate advanced sensors and smart defrost technology to enhance performance further. These sensors continuously monitor key variables like coil temperature, humidity, and frost buildup, enabling precise sensor calibration to guarantee accurate data. With smart algorithms, the system adapts its defrost cycle based on real-time conditions, reducing unnecessary defrosts and conserving energy. This targeted approach minimizes energy waste and maintains ideal heat pump operation. You benefit from improved energy efficiency and reduced operational costs. By integrating these advanced sensors and intelligent controls, your heat pump becomes more responsive, reliable, and capable of maintaining peak performance even in harsh winter conditions. Additionally, AI-powered sensors can predict frost formation patterns more accurately, further optimizing defrost cycles.

Frequently Asked Questions

How Do Outdoor Weather Conditions Impact Defrost Cycle Frequency?

Outdoor temperature and humidity levels directly impact how often your heat pump needs to defrost. When it’s colder outside, your system detects ice build-up more quickly, increasing defrost cycle frequency. High humidity can also cause more frost to form on the outdoor coil. As a result, you’ll notice your heat pump entering defrost mode more often in chilly, humid conditions to maintain efficient operation.

What Maintenance Is Needed for Optimal Defrost System Performance?

To keep your heat pump’s defrost system working well, you should regularly check refrigerant flow and guarantee coil cleanliness. Proper refrigerant flow prevents ice buildup, while clean coils allow heat to transfer efficiently. Schedule routine inspections and cleaning, especially before cold weather hits. This maintenance helps your system run smoothly, reduces energy costs, and extends its lifespan. Keep these key areas in mind for maximum performance.

Can Defrost Cycles Affect Overall Heat Pump Efficiency?

You might think defrost cycles don’t impact your heat pump’s efficiency, but they do. When a defrost cycle occurs, it temporarily interrupts heat transfer, reducing overall performance. Frequent or lengthy defrost cycles can lower your system’s efficiency and increase energy use. Understanding how the defrost cycle affects heat transfer helps you optimize operation—so your heat pump runs smoothly and saves energy even in cold weather.

Are There Environmental Considerations With Different Defrost Methods?

When choosing defrost methods, you should consider environmental impacts like refrigerant choice, as some refrigerants have higher global warming potential. Eco-friendly refrigerants reduce your carbon footprint and help protect the environment. Different defrost strategies may use varying refrigerants or energy sources, so selecting a method that minimizes environmental harm is essential. By prioritizing eco-friendly refrigerants, you guarantee your heat pump operates efficiently while being environmentally responsible.

How Does User Intervention Influence Defrost System Operation?

User influence, especially through manual control, can markedly impact how the defrost system operates. When you intervene manually, you can trigger defrost cycles at ideal times, potentially improving efficiency and comfort. However, improper or excessive manual control may cause unnecessary defrosting, wasting energy. It’s crucial to understand your system’s guidelines so your input enhances performance without causing inefficiencies or environmental concerns.

Conclusion

Think of defrost strategies like a skilled conductor guiding an orchestra, ensuring each instrument plays in harmony. By choosing the right defrost mode—whether temperature-based, time-triggered, reverse cycle, or smart technology—you keep your heat pump running smoothly, even in harsh conditions. This coordination prevents ice buildup, maintaining warmth and efficiency. With the right defrost approach, your system stays in tune, delivering reliable comfort just like a well-conducted symphony.