Innovative compressor tech in modern heat pumps boosts efficiency, reliability, and eco-friendliness. Features like scroll compressors with variable speeds, two-stage and inverter-driven models, allow precise control and better performance in cold climates. Using low-GWP refrigerants, these compressors reduce environmental impact. Smart diagnostics and IoT integration help maintain ideal operation and extend lifespan. If you stay engaged, you’ll uncover more about how these advancements are shaping future heat pump innovations.

Key Takeaways

- Modern heat pumps utilize variable-speed and inverter-driven compressors for precise capacity control and increased energy efficiency.

- Advanced scroll and multi-stage compressor designs improve performance in cold climates and enable smoother, more reliable operation.

- Use of low-GWP refrigerants with innovative compressors reduces environmental impact while maintaining high efficiency.

- Vapor injection (EVI) and space-grade turbocompressors enable heat pumps to operate efficiently below -22°F.

- Enhanced durability features like advanced sealing, thermal management, and oil-free designs extend compressor lifespan and system reliability.

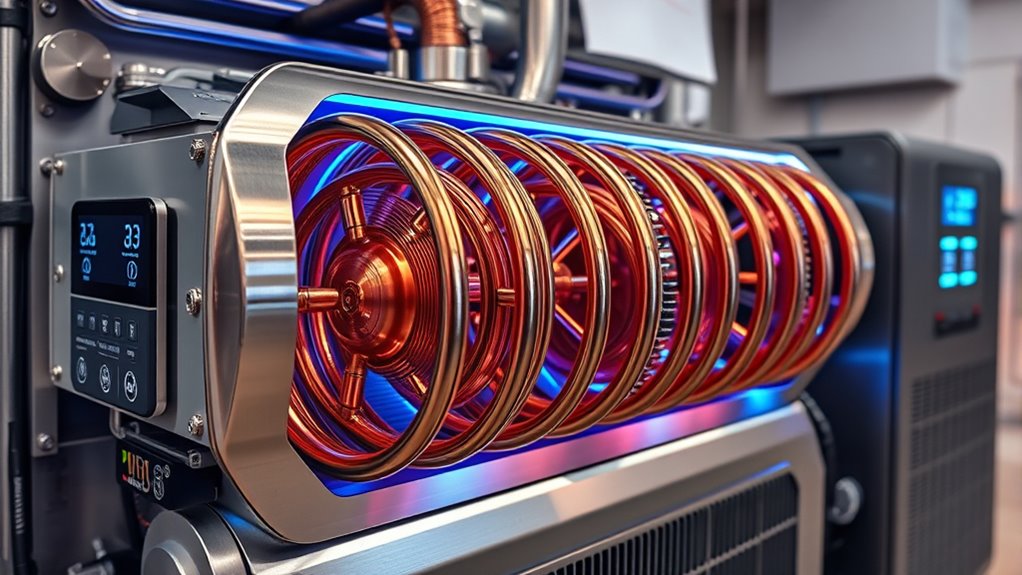

Advancements in Scroll Compressor Technology

Advancements in scroll compressor technology have considerably improved the performance and efficiency of modern HVAC systems. Scroll compressors, especially variable-speed models, adjust capacity dynamically, optimizing refrigerant flow for better compressor efficiency. This adaptability allows for precise temperature control, enhancing comfort and system responsiveness. Additionally, the integration of AI-powered control systems in some models enables more accurate and responsive operation, further improving overall system performance. This innovation enhances heat pump technology by providing precise temperature control and reducing energy consumption—sometimes by as much as 30%. Modern scroll compressors also incorporate advanced sealing techniques that minimize internal leaks and improve durability, extending system lifespan. These manufacturing advancements contribute to improved component reliability, ensuring longer-lasting performance. Multi-scroll configurations further boost capacity and efficiency, making them suitable for a wide range of applications. Newer models incorporate advanced sealing techniques and low-voltage inverter drives, enabling rapid speed modulation even in cold climates and partial load conditions. These innovations lead to smoother operation, increased reliability, and significant energy savings, ensuring that modern heat pumps deliver top-tier performance while consuming less power.

The Role of Two-Stage and Variable Speed Compressors

Two-stage and variable speed compressors play a vital role in enhancing HVAC system performance by offering precise control over heating and cooling outputs. These compressor technologies optimize heat pump efficiency through modulation technology, adjusting capacity to demand. Using two-stage compressors, you benefit from better temperature control and higher seasonal efficiency, especially in cold climates. Variable speed compressors continuously modify motor speed, ensuring energy savings and smooth operation. Additionally, the ability to modulate compressor capacity allows systems to adapt more effectively to fluctuating conditions, further improving efficiency. This adaptability also helps in reducing system wear, leading to a longer lifespan for the equipment. Incorporating advanced compressor designs can further elevate system reliability and performance. Key benefits include:

- Improved cold climate performance and seasonal efficiency

- Reduced system wear and extended lifespan

- Enhanced energy savings through precise modulation

Inverter-Driven Compressors for Precise Control

Inverter-driven compressors give you precise temperature control by adjusting their speed in real-time to match your home’s needs. This reduces system cycling, leading to more consistent comfort and less wear on your equipment. As a result, you enjoy better efficiency, quieter operation, and longer-lasting performance. Additionally, the ability of inverter-driven compressors to adapt their operation helps mitigate issues related to high omega-3 content, which could affect blood clotting if not properly managed. Incorporating advanced compressor technology can further optimize system performance and energy savings over traditional models. Furthermore, fostering creative practice in designing these systems encourages innovative solutions that enhance durability and effectiveness. Utilizing energy-efficient components can also contribute to reducing overall energy consumption and environmental impact. Understanding system integration can help maximize the benefits of inverter-driven compressors in modern heat pump systems.

Enhanced Temperature Precision

By adjusting motor speeds in real-time, inverter-driven compressors deliver precise temperature control, ensuring your system responds quickly to indoor fluctuations. This advanced inverter technology modulates the compressor’s variable speeds, maintaining a consistent indoor climate regardless of external conditions. These features enhance heat pump performance through superior temperature regulation and energy efficiency. Key benefits include:

- Precise temperature maintained even in extreme cold conditions

- Reduced energy consumption by adjusting speeds as needed

- Longer system lifespan due to soft-start capabilities and minimized stress

- The adaptive control capabilities of inverter-driven compressors help optimize performance across varying environmental conditions

- Additionally, thermal management techniques prevent overheating and improve overall system reliability. Incorporating industry-leading technologies further boosts efficiency and durability.

- Furthermore, understanding local store hours can help plan maintenance or purchases to ensure your system operates smoothly year-round.

With inverter-driven compressors, you’ll enjoy ideal temperature control, quicker adjustments, and reliable operation, making your heat pump more effective and efficient—no matter how harsh the weather gets.

Reduced System Cycling

Have you ever noticed how traditional HVAC systems often cycle on and off frequently, causing wear and reducing efficiency? Inverter technology addresses this by adjusting compressor speed continuously, reducing system cycling. Instead of start-stop cycles, the inverter modulates compressor speed to match indoor demand, providing precise temperature modulation. This results in less system wear and extended equipment lifespan. By maintaining steady indoor temperatures with fewer on/off cycles, your heat pump performs more efficiently. Inverter-driven compressors can operate effectively even at lower outdoor temperatures, boosting overall heat pump performance. Plus, this precise control improves energy efficiency, with data showing up to 30% savings compared to fixed-speed systems. Reduced system cycling not only enhances comfort but also prolongs your system’s operating efficiency. Managing Bitcoin Volatility strategies such as real-time monitoring can further optimize system performance and longevity. Additionally, understanding system cycling helps in selecting the most suitable compressor technology for your needs.

Low-GWP Refrigerants and Environmental Impact

Switching to low-GWP refrigerants like R-454B and R-32 helps reduce the environmental impact of HVAC systems. These eco-friendly options allow you to meet stricter regulations while maintaining efficient heat transfer. Embracing sustainable refrigerants is a key step toward greener, more responsible cooling and heating solutions. Utilizing Gold IRA options can also serve as a strategic way to diversify investments and protect assets amid shifting economic and environmental landscapes. Incorporating environmentally friendly refrigerants is essential for future-proofing HVAC systems against evolving regulations and climate goals.

Eco-Friendly Refrigerant Choices

Ever wondered how modern heat pumps are becoming more environmentally friendly? The answer lies in choosing eco-friendly refrigerant options like low-GWP refrigerants and natural refrigerants. These alternatives, including R-454B, R-290, and R-32, drastically reduce environmental impact by lowering global warming potential. They support sustainability goals and meet regulatory standards. Advanced refrigerant formulation ensures these eco-conscious choices maintain excellent heat transfer performance, even with lower GWP. Here’s a quick look:

- Low-GWP refrigerants like R-454B and R-32 cut down greenhouse gas emissions

- Natural refrigerants such as R-290 and R-744 have negligible GWP and are eco-friendly

- Innovations in refrigerant formulation optimize efficiency and environmental benefits

- Refrigerant properties and their potential to affect system reliability are important considerations in selecting eco-friendly options. Additionally, ongoing research aims to improve the reliability of low-GWP refrigerants to ensure long-term performance.

Reducing Global Warming

Reducing global warming is a critical goal for modern heat pump technology, and low-GWP refrigerants play an essential role in achieving it. By using eco-friendly refrigerants like R-454B and R-32, you can considerably decrease greenhouse gas emissions and lower the global warming potential of heat pump systems. Advanced compressor technologies enable these environmentally friendly refrigerants to perform efficiently without sacrificing performance. These innovations make it easier to integrate low-GWP refrigerants into existing systems, supporting climate change mitigation efforts. As regulations tighten, adopting such refrigerants with advanced compressors ensures your heat pumps remain compliant while reducing their environmental footprint. Ultimately, this approach helps you contribute to global efforts to combat climate change and promotes sustainable, eco-conscious HVAC solutions.

Sustainable HVAC Innovations

Have you considered how innovative refrigerants are transforming HVAC sustainability? Low-GWP refrigerants, like R-454B, reduce global warming potential without sacrificing heat pump efficiency. These eco-friendly refrigerants support climate-friendly HVAC and decarbonization efforts. Advances in compressor technology enable the effective use of refrigerant innovations, ensuring reliable performance across various climates. Here’s how these innovations make a difference:

- Adoption of natural refrigerants and advanced compressor designs minimizes pollutants

- Enhanced compressor efficiency boosts sustainability in heat pump systems

- Regulations favor low-GWP refrigerants, aligning with global decarbonization goals

Enhanced Reliability in Cold Climate Operations

Innovative compressor technologies substantially enhance reliability when operating in cold climates. Advanced compressor designs, like space-grade turbocompressors, enable heat pumps to perform efficiently at temperatures below -22°F, ensuring consistent comfort even in extreme conditions. These innovations often eliminate oil-based lubricants and use natural refrigerants, reducing environmental impact and improving reliability in harsh environments. High-efficiency, space-derived compressors maintain steady heating capacity and COP across severe winter temperatures. Incorporating features like vapor injection (EVI) boosts performance and heating capacity in sub-zero outdoor conditions. These advancements allow heat pumps to operate reliably in cold climates, delivering sustained efficiency and performance despite the challenges posed by extreme temperatures. As a result, your system becomes more resilient and capable of handling demanding operating conditions.

Smart Diagnostics and IoT Integration in Compressors

Building on advancements that improve compressor reliability in cold climates, integrating Smart Diagnostics and IoT technology takes system performance to the next level. IoT-enabled compressors, like Ecoer’s TDi Pro 2 Series, continuously monitor system health and detect faults in real-time. This allows for:

- Remote troubleshooting and maintenance alerts

- Data-driven predictive maintenance to prevent failures

- Automatic operation adjustments based on sensor data

These features help HVAC professionals perform proactive maintenance, reduce downtime, and extend equipment lifespan. Smart diagnostics provide detailed insights into compressor performance, enabling quick identification of issues before they escalate. By connecting to the cloud, these systems optimize efficiency and reliability, ensuring your heat pump operates smoothly and cost-effectively. IoT integration truly transforms compressor management in modern HVAC systems.

Future Trends in Compressor Innovation for Heat Pumps

Advancements in compressor technology are poised to revolutionize heat pump performance, especially in cold climates. Future compressor innovation will focus on developing cold climate heat pumps with enhanced low-temperature performance, utilizing advanced vapor injection and variable-speed compressors. Space-grade turbocompressors, inspired by aerospace technology, promise to boost efficiency by 50% and operate reliably down to -22°F. These designs eliminate oil-based lubricants and incorporate natural refrigerants, reducing environmental impact and increasing resilience. As these innovations scale for residential and commercial use, they’ll drive energy efficiency and expand heat pump adoption in colder regions. The integration of aerospace-inspired designs and advanced vapor injection techniques will set new standards, making cold climate heat pumps more reliable, sustainable, and cost-effective.

Frequently Asked Questions

What Type of Compressor Is Best for Heat Pumps?

You should choose an inverter-driven scroll or rotary compressor for your heat pump. These compressors are highly efficient, provide precise temperature control, and can adjust their capacity to match your heating needs. If you live in a cold climate, a variable-speed or dual-stage compressor offers better performance at low temperatures. Natural refrigerant-compatible models also help you stay eco-friendly without sacrificing reliable heating.

What Are the Changes in Heat Pumps 2025?

Imagine upgrading your home with a heat pump in 2025, and it seamlessly heats your space even when it’s -30°F outside. That’s thanks to new compressor tech like space-grade turbocompressors and advanced vapor injection systems. You’ll benefit from smarter controls, IoT connectivity, and eco-friendly refrigerants. These innovations make your heat pump more efficient, reliable, and suitable for colder climates, transforming your comfort and energy savings.

What Is the New Refrigerant for Heat Pumps?

You’re asking about the new refrigerant in heat pumps, which is R-454B. This refrigerant has a lower GWP compared to older options like R-410A, making it more environmentally friendly. It’s classified as an A2L mildly flammable refrigerant, offering better efficiency while meeting strict environmental standards. By using R-454B, you’re supporting eco-friendly systems that provide reliable heating and cooling with less impact on the planet.

What Type of Compressor Is Most Likely to Have a Heat Pump?

Think of a heat pump’s compressor as the heart pumping efficiency through your system. You’re most likely to see scroll compressors in modern heat pumps because they’re reliable, quiet, and efficient. Inverter-driven models adapt to your heating or cooling needs, saving energy. Plus, enhanced vapor injection compressors excel in cold climates. These technologies work together like a well-orchestrated symphony, ensuring your heat pump operates smoothly and effectively.

Conclusion

As you marvel at these cutting-edge compressor techs, it’s amusing to think that future innovations might make today’s models seem quaint. With smarter diagnostics and eco-friendly refrigerants, your heat pump could soon run so efficiently that you’ll wonder how you ever managed before. Ironically, as we chase perfection, we might just find ourselves marveling at how simple these “futuristic” systems are compared to the old, noisy, less reliable units of yesteryear.