Advancements in refrigeration technology are making heat pumps more efficient, reliable, and eco-friendly. Modern compressors now include variable-speed and colder climate designs that improve performance and lifespan. Innovations in low-GWP refrigerants, like CO₂ and hydrocarbons, support environmental goals. Enhanced heat exchange materials and smart control systems optimize operation and defrosting in cold weather. Exploring these developments reveals how future-proof solutions are transforming heating and cooling solutions worldwide.

Key Takeaways

- Development of low-GWP refrigerants like CO₂, hydrocarbons, and HFOs enhances environmental sustainability in heat pump systems.

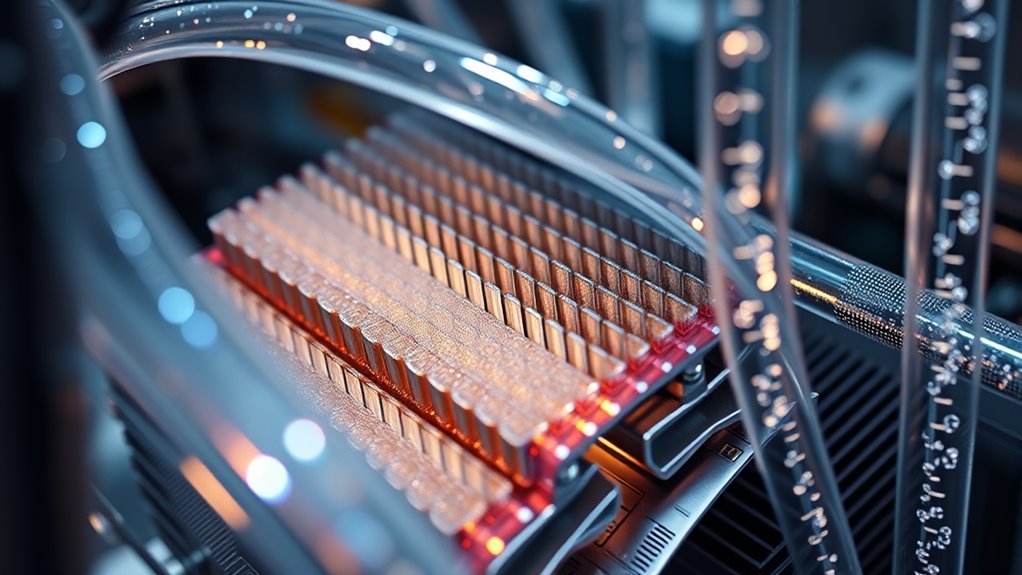

- Microchannel heat exchange coils and nanostructured surfaces improve heat transfer efficiency in refrigeration components.

- Variable-speed compressors and advanced control systems optimize operation, energy efficiency, and system lifespan.

- Ice detection sensors and adaptive defrost algorithms reduce energy waste and maintain performance in cold climates.

- Integration of IoT and smart controls enables remote monitoring, predictive maintenance, and adaptive system optimization.

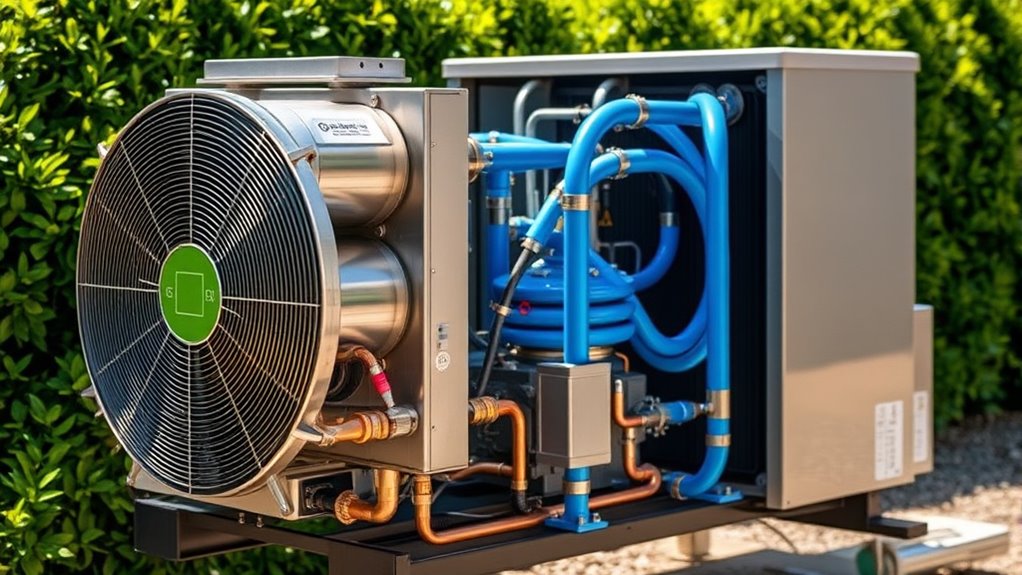

Enhanced Compressor Technologies and Variable-Speed Operation

Enhanced compressor technologies and variable-speed operation have revolutionized heat pump performance by allowing units to adapt seamlessly to changing heating or cooling demands. With variable-speed compressors, heat pump technology now offers superior efficiency by precisely matching capacity through compression modulation. Advanced compressor designs, like scroll and rotary types, improve heat transfer, resulting in quieter operation and greater reliability. These innovations enable cold climate heat pumps to operate effectively even in extremely low temperatures, providing consistent comfort and energy savings. By continuously adjusting capacity, you avoid unnecessary cycling, reducing wear and tear on the system. Additionally, compressor efficiency improvements contribute to longer equipment lifespan and reduced maintenance costs. The integration of smart controls further optimizes system operation by adjusting performance based on real-time conditions. Moreover, incorporating region-specific adaptations ensures these systems perform optimally across diverse climates and environments. Furthermore, ongoing research into refrigerant technologies aims to enhance environmental sustainability and system performance. Advancements in manufacturing processes also help improve the overall durability and cost-effectiveness of heat pump components. Overall, these developments make modern heat pumps more efficient, durable, and capable of delivering reliable heating and cooling in diverse environments.

Development of Low-GWP and Environmentally Friendly Refrigerants

As concerns about environmental impact grow, the development of low-GWP refrigerants has become a critical focus in heat pump technology. You now see a shift toward environmentally friendly refrigerants like CO₂, hydrocarbons such as R290, and ammonia, replacing traditional HFCs. CO₂ heat pumps excel in cold climates, thanks to their high pressure tolerance and natural refrigerant qualities. Hydrocarbon refrigerants like propane offer high efficiency and low GWP but require strict safety standards due to flammability. Advances in refrigerant blends aim to optimize refrigerant efficiency while ensuring compliance with refrigerant standards. These innovations support climate-friendly refrigeration and meet regulatory pressures, including the Kigali Amendment. Additionally, ongoing research into refrigerant lifecycle and environmental sustainability aims to improve sustainability by reducing environmental impacts throughout the entire product lifespan. Developing refrigerant management strategies is crucial for minimizing leaks and reducing ozone depletion and global warming potential. Overall, developing low-GWP refrigerants is essential for sustainable heat pump systems and reducing environmental impact. SampleTraxx offers a variety of sound effects that can be used in educational videos about technological advances.

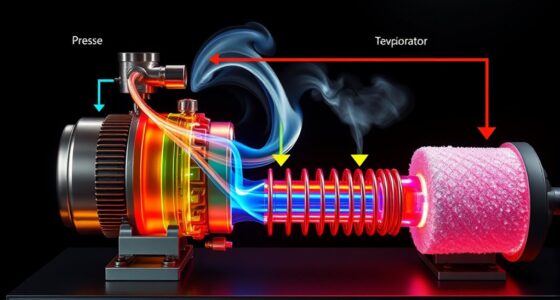

Advanced Heat Exchange Materials and Design Innovations

Innovations in heat exchange materials and design are transforming heat pump performance by substantially boosting heat transfer efficiency. Microchannel coils and enhanced aluminum alloys improve thermal conductivity, enabling up to 30% better heat transfer than traditional copper and fin designs. Nanostructured surfaces further increase surface area and promote turbulence, enhancing heat exchange. Advanced heat exchanger geometries, optimized through CFD, maximize airflow and surface contact, boosting thermal rates. Incorporating phase change materials allows better thermal storage and load regulation, ensuring system stability. High-performance composites and thermally conductive ceramics reduce weight, corrosion, and extend lifespan, while specialized coatings prevent frost buildup, maintaining efficiency in cold climates. Additionally, utilizing refrigerant with improved thermodynamic properties further enhances system efficiency and environmental sustainability. Recent developments in heat pump components focus on reducing energy consumption and improving reliability, making these systems more adaptable to different environments. To further improve performance, researchers are exploring advanced manufacturing techniques that enable more complex and efficient heat exchange designs. These innovations collectively push heat pump technology toward higher efficiency, durability, and adaptability across diverse operating conditions.

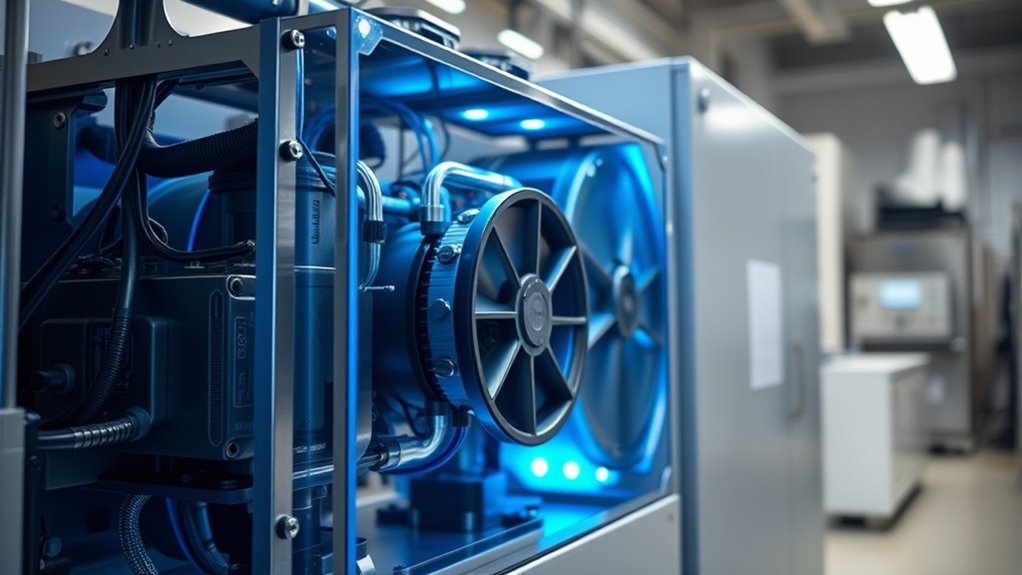

Intelligent Control Systems and Smart Thermostat Integration

Intelligent control systems and smart thermostat integration are revolutionizing how heat pumps operate by enabling more precise and efficient management of heating and cooling. With smart thermostats, you can benefit from machine learning algorithms that adapt schedules based on your habits, optimizing energy efficiency. IoT-enabled control allows remote monitoring and operation via smartphone apps, giving you real-time system data and control. Environmental sensors and weather data automatically adjust system performance for maximum efficiency in changing conditions. Integration with smart home ecosystems enables seamless scheduling, automation, and maintenance alerts, enhancing convenience and system longevity. Additionally, data collection from these intelligent systems also support predictive maintenance, reducing downtime and ensuring your heat pump performs at peak efficiency. Recent studies highlight that increased smart device adoption among homeowners further enhances the capabilities and benefits of these advanced systems. Furthermore, the integration of environmental sensors helps optimize system responses to external factors, improving overall performance and energy savings.

Improvements in Defrosting Mechanisms for Cold Climates

Modern heat pumps now use ice detection sensors and smart algorithms to identify frost buildup early, reducing unnecessary defrost cycles. Reverse cycle defrost methods allow the system to melt ice without halting heating, improving efficiency. These innovations help prevent performance issues and extend the lifespan of cold climate heat pumps. Additionally, natural techniques such as organic refrigerants and environmentally friendly defrosting methods contribute to sustainable operation in cold climates. Incorporating heat pump advancements and seed allergy awareness into design considerations can also enhance safety and user confidence in these systems. Advances in defrosting mechanisms further optimize operation by minimizing energy consumption during defrost cycles, with innovative control systems playing a key role in efficiency.

Ice Detection Technologies

Ice detection technologies have revolutionized how heat pumps manage defrosting in cold climates by using sensors and algorithms to detect ice buildup accurately. These systems leverage infrared or ultrasonic sensors to monitor ice thickness and formation patterns in real-time, enabling precise responses. With advanced technology, defrost systems activate only when necessary, reducing unnecessary cycles. This targeted approach improves system efficiency and helps preserve system performance during winter storms, extending equipment lifespan and enhancing heat pump efficiency by up to 20%. Incorporating sensor technology further improves the accuracy and reliability of ice detection systems, ensuring optimal defrost cycles. Effective ice management is crucial for maintaining reliable operation and energy savings in harsh winter conditions. Additionally, ongoing innovations in automated control systems continue to optimize defrosting processes, contributing to overall system durability and performance.

Automated Defrost Cycles

How do advancements in automated defrost cycles enhance heat pump performance in cold climates? Modern heat pumps use automated defrost systems with advanced sensors and algorithms to detect ice buildup on coils. These sensors monitor conditions in real-time, triggering defrost cycles only when necessary, which conserves energy. Improved defrost systems incorporate rapid-response heating elements and optimized airflow to melt frost efficiently without disrupting heating performance. Real-time monitoring allows precise control over defrost timing, reducing unnecessary cycles and boosting energy efficiency. Adaptive defrost algorithms analyze temperature and humidity data to determine the best possible frequency, preventing excessive defrosting. Incorporating advanced sensor technology into these systems can improve visual indicators and diagnostics for technicians. These innovations help maintain consistent heat pump performance during winter, minimize frost-related issues, and extend equipment lifespan, making heat pumps more reliable and cost-effective in cold climates.

Frost Prevention Strategies

To effectively prevent frost buildup in cold climates, heat pump systems now incorporate advanced defrosting mechanisms that proactively address ice formation. These systems use frost sensors and defrost algorithms to detect frost buildup early and initiate defrost cycles only when needed, boosting frost prevention and efficiency. Modern reverse cycle defrost technology temporarily reverses refrigerant flow, melting frost without halting operation. Enhanced defrost mechanisms include optimized fan control and variable-speed compressors, reducing energy waste during defrost cycles. Infrared or contactless sensors monitor coil temperature, enabling faster, more precise defrost responses.

- Feel confident knowing your heat pump fights frost automatically, conserving energy and maintaining warmth.

- Experience uninterrupted comfort thanks to smarter frost detection and faster defrosting.

- Trust in improved frost algorithms that keep your system efficient even in harsh winter conditions.

Hybrid and Dual-Fuel Heat Pump Systems

Hybrid and dual-fuel heat pump systems combine electric heat pumps with gas furnaces to enhance efficiency and reliability, especially during cold weather. These hybrid systems automatically switch between heat pump mode and gas heating based on outdoor temperatures, ensuring consistent warmth and reducing energy costs. Dual-fuel heat pumps optimize system integration by selecting the most cost-effective energy source, leveraging fluctuations in electricity and natural gas prices. Incorporating smart controls helps fine-tune switching points, maximizing energy efficiency and extending system lifespan. These systems are particularly advantageous in extreme cold climates where heat pump performance diminishes. By blending refrigeration technology with traditional heating methods, they offer a reliable, cost-effective solution that adapts to weather conditions, ensuring comfort and savings year-round.

Applications of Refrigeration Advances in Decarbonization Efforts

Advances in refrigeration technology, like low-GWP refrigerants, help reduce the environmental impact of heat pumps and support global decarbonization goals. These innovations also improve system efficiency, enabling heat pumps to operate effectively in colder climates and industrial settings. By adopting these developments, you can accelerate the shift away from fossil fuels and contribute to climate commitments.

Low-GWP Refrigerants Adoption

The adoption of low-GWP refrigerants such as CO₂, hydrocarbons, and ammonia plays a crucial role in reducing the environmental impact of heat pump systems. These refrigerant technologies enable you to operate systems that are more environmentally friendly, with some achieving GWP values below 1. As regulations like the Kigali Amendment accelerate the phase-out of high-GWP refrigerants, switching to sustainable alternatives becomes essential. Low-GWP refrigerant systems often require high-pressure components, but recent advancements have made them safer and viable for various applications. By embracing these alternatives, you contribute to lowering carbon emissions and supporting global decarbonization efforts.

- Feel empowered knowing your choices directly reduce greenhouse gases

- Witness the positive impact of sustainable refrigerant flow

- Be part of a future where eco-friendly heat pumps lead the way

Enhancing System Efficiency

Recent developments in refrigeration technology have considerably boosted heat pump efficiency, making them more effective tools in reducing energy consumption and lowering carbon emissions. You now benefit from advanced compressors, like variable-speed inverter types, which adjust capacity precisely, reducing waste. Optimized heat exchangers improve heat transfer, enhancing system efficiency. Low-GWP refrigerants, such as CO₂ and hydrocarbons, boost performance while supporting decarbonization. Smart control systems enable real-time optimization of refrigerant flow and compressor operation, adapting to changing conditions. Enhanced defrost systems with sensors prevent frost buildup, maintaining efficiency during cold weather. Together, these innovations create a more reliable, eco-friendly heat pump:

| Technology | Impact |

|---|---|

| Variable-speed compressor | Precise capacity control, reduced energy waste |

| Heat exchanger | Improved heat transfer, higher efficiency |

| Smart control systems | Real-time optimization, better performance |

| Defrost systems | Minimized frost, consistent operation |

Supporting Climate Goals

Innovative refrigeration technologies play a crucial role in supporting global efforts to reduce carbon emissions. By adopting low-GWP refrigerants like CO₂ and hydrocarbons, you help minimize environmental impact and advance climate goals. Refrigeration advancements, such as improved heat transfer efficiency and advanced refrigeration components, enable heat pumps to operate effectively across diverse and cold climates. Enhanced defrost systems and intelligent controls ensure consistent performance during winter, reducing energy waste. These innovations promote heat pump decarbonization, replacing fossil fuel-based heating systems. You contribute to building decarbonization by choosing environmentally friendly refrigerants and cutting-edge technology.

- Support global climate initiatives

- Reduce greenhouse gas emissions

- Enable sustainable heating solutions

Future Trends and Emerging Technologies in Refrigeration for Heat Pumps

Advancements in refrigeration technologies are shaping the future of heat pump efficiency and sustainability. You’ll see a shift toward eco-friendly refrigerants with low GWP, like hydrofluoroolefins (HFOs), propane (R290), and CO₂ systems, reducing environmental impact. Innovations in compressor and expansion valve designs enable better heat transfer, even in colder climates. Advanced sensors and control systems optimize refrigerant flow, improving performance and reliability. Magnetic refrigeration presents a promising, energy-efficient alternative, leveraging magnetic fields instead of traditional refrigerants. Below is a snapshot of emerging technologies:

| Technology | Key Benefits |

|---|---|

| Low GWP refrigerants | Eco-friendliness, regulatory compliance |

| Advanced sensors | Enhanced performance, heat transfer |

| Magnetic refrigeration | High efficiency, sustainability |

Frequently Asked Questions

What Is the New Refrigerant for Heat Pumps?

You’re asking about the new refrigerants for heat pumps. Right now, low-GWP options like CO₂ (R744), propane (R290), and ammonia lead the way. These refrigerants are eco-friendlier, offering similar or better efficiency than older ones. They’re designed to work well in various climates, including cold environments, and are part of global efforts to reduce environmental impact by replacing high-GWP substances.

What Are the Changes in Heat Pumps 2025?

In 2025, you’ll notice significant changes in heat pumps. They now use low-GWP refrigerants like R-32, R-1234yf, and CO₂, making them more environmentally friendly. You’ll also see advanced inverter compressors that adapt to your heating or cooling needs more precisely. Improved heat exchangers and smart controls make these systems more efficient and reliable, especially in colder weather. Hybrid refrigerant systems further enhance performance while reducing environmental impact.

What Is the Primary Refrigeration Problem in a Heat Pump System?

The primary refrigeration problem in a heat pump system is managing refrigerant flow efficiently across changing outdoor temperatures to guarantee effective heat transfer. You face challenges like ice buildup during defrost cycles, which hampers circulation, and difficulties in handling high-pressure, low-temperature refrigerants in cold climates. Precise control of refrigerant phase changes and addressing leaks or pressure drops are essential to maintain system efficiency and reliable operation.

What Technological Advancement Has Significantly Contributed to the New Generation of Heat Pump Systems Mentioned in the Passage?

You’re asking about a key technological advancement that has shaped modern heat pump systems. You should know that the development of variable-speed, inverter-driven compressors plays a major role. These compressors let you modulate capacity and operate efficiently even in cold outdoor temperatures. This innovation improves performance, energy savings, and reliability, making heat pumps more effective and adaptable to different climate conditions, especially during winter.

Conclusion

As you explore these advancements, you’ll notice how innovations like variable-speed compressors and eco-friendly refrigerants boost efficiency and reduce environmental impact. Did you know that modern heat pumps can cut energy use by up to 50% compared to traditional systems? Embracing these technologies not only improves comfort but also plays a crucial role in decarbonization efforts. Staying informed about these trends helps you make smarter, greener choices for heating and cooling your home.