The refrigeration cycle in heat pumps works by moving heat between indoor and outdoor spaces using refrigerant phase changes and pressure shifts. The compressor increases refrigerant pressure and temperature, allowing it to release heat through the condenser. Then, the expansion valve drops pressure, turning refrigerant into a cold mixture, which absorbs heat in the evaporator. Understanding these components and their roles helps explain how heat pumps efficiently provide heating and cooling—if you explore further, you’ll discover more about how this seamless process operates.

Key Takeaways

- Heat pumps transfer heat by circulating refrigerant through phase changes, absorbing heat in the evaporator and releasing it in the condenser.

- The compressor increases refrigerant pressure and temperature, enabling effective heat transfer from cold to warm areas.

- The expansion valve reduces refrigerant pressure, causing it to evaporate and absorb heat efficiently during the cooling cycle.

- Phase changes—vaporization and condensation—are essential for transferring heat between indoor and outdoor environments.

- Smart controls and sensors optimize the cycle by adjusting component operation based on temperature fluctuations, improving efficiency.

Understanding Thermodynamics and Heat Flow

Understanding thermodynamics and heat flow is essential to grasp how heat pumps transfer thermal energy. The refrigerant plays a key role by facilitating heat transfer through phase changes and pressure adjustments. When the refrigerant’s pressure increases, its temperature rises, allowing it to absorb heat from a cold area. Conversely, reducing pressure lowers its temperature, enabling heat to be released into a warmer space. This pressure-temperature relationship is fundamental because it allows controlled heat transfer against the natural flow from high to low temperature. External work, often from a compressor, is necessary to manipulate the refrigerant’s pressure and temperature. Additionally, Kia Tuning techniques can optimize the performance of heat pumps by improving component efficiency and system response. The efficiency of the entire cycle depends heavily on maintaining proper heat flow dynamics, which are governed by thermodynamic principles. Proper system design is crucial for maximizing energy efficiency and ensuring reliable operation. By understanding these principles, you see how thermodynamics enables the efficient transfer of heat, powering the refrigeration cycle in heat pumps. Furthermore, advancements in component materials contribute to reducing energy consumption and enhancing durability of heat pump systems.

Key Components of the Refrigeration Cycle

The refrigeration cycle relies on four essential components that work together to transfer heat efficiently. These are the compressor, condenser, expansion valve, and evaporator. The compressor plays a key role by increasing the refrigerant’s pressure and temperature, preparing it for heat transfer. The condenser cools the high-pressure refrigerant vapor, turning it into a liquid while releasing heat to the surroundings. The expansion valve then reduces the refrigerant’s pressure rapidly, causing it to cool further. A crucial aspect of system performance is the Suction power, which is vital for moving the refrigerant efficiently through the system, ensuring optimal performance. Proper system efficiency depends on the proper functioning of these components working in harmony. The compressor’s performance can be affected by regulatory standards, which ensure safety and environmental compliance. Finally, the evaporator absorbs heat as the low-pressure refrigerant vaporizes, enabling the cycle to repeat.

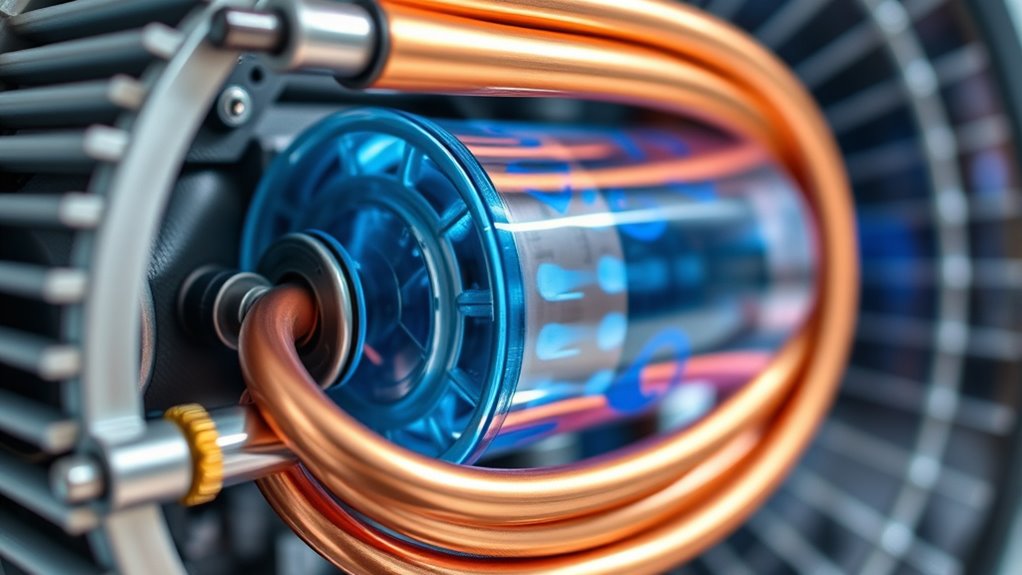

The Role of the Compressor in Heat Pump Operation

Have you ever wondered how a heat pump moves heat from one place to another? The compressor plays a crucial role in this process. It compresses the refrigerant vapor, transforming it from a low-pressure, low-temperature state into a high-pressure, high-temperature gas. This increase in temperature is essential for efficient heat transfer. Powered by an electric motor, the compressor supplies the energy needed to raise the refrigerant’s pressure and temperature during compression. Its efficiency directly affects the heat pump’s overall performance and energy use. Different types of compressors, like reciprocating or scroll, offer varying efficiency levels suited for specific applications. By maintaining continuous refrigerant flow, the compressor ensures consistent heat transfer, whether heating or cooling your space. The materials used in compressor construction can influence durability and operational efficiency, impacting the longevity of the system. Additionally, advances in compressor design continue to improve energy efficiency and reliability in heat pump systems. For optimal operation, selecting the right compressor type based on system requirements is essential for achieving peak performance. Furthermore, proper maintenance practices can extend the lifespan and optimize the performance of the compressor over time.

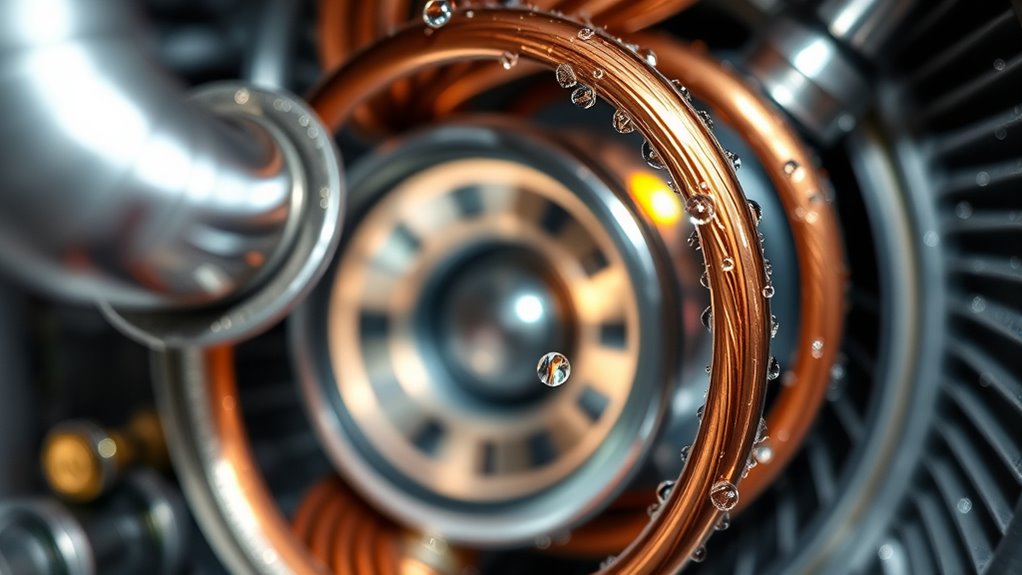

How the Condenser Facilitates Heat Release

The condenser is where your heat pump releases heat to the outside environment. As high-pressure refrigerant cools and condenses, it transfers heat through its coils, warming the air or water around it. Proper airflow or water flow over the coils is essential to maximize heat dissipation and keep your system running efficiently. Regular maintenance, including cleaning the coils and replacing filters, helps ensure optimal heat transfer and prolongs the lifespan of your system.

Heat Dissipation Process

How does a heat pump’s condenser effectively release heat? It acts as a heat exchanger, transferring heat from high-pressure, high-temperature refrigerant to the outside environment. As the refrigerant condenses from vapor to liquid, it releases latent heat, which is then dissipated through fins, coils, or water flows. Fans or water pumps boost airflow or water movement, increasing heat rejection efficiency. The condenser’s surface area, fin design, and temperature difference with the surroundings all influence how well heat is expelled. Proper subcooling of the refrigerant maximizes heat rejection, ensuring the system operates efficiently. Additionally, crochet styles for locs can be used to protect the system components from environmental stressors, enhancing durability. Understanding the heat transfer process involved in this phase is essential for optimizing system performance, especially as thermal conductivity impacts how quickly heat can be transferred away from the refrigerant. Enhancing heat transfer efficiency can lead to more effective cooling performance and energy savings.

Heat Exchange Efficiency

Efficient heat exchange in a condenser hinges on several key design factors that optimize the transfer of thermal energy from the refrigerant to the environment. The condenser, acting as a heat exchanger, must maximize surface area, often through fin arrangements, to improve heat transfer. Proper airflow over the coils enhances heat release, ensuring the refrigerant condenses effectively from vapor to liquid by removing latent heat. Subcooling the refrigerant ensures maximum heat transfer and prevents vapor formation in the liquid line, boosting efficiency. The temperature difference between the refrigerant and ambient air is critical; greater differences accelerate heat rejection. When these elements are optimized, the condenser facilitates effective heat exchange, ensuring the heat pump operates efficiently and reliably during heat release.

The Function of the Expansion Valve or Restriction Device

The expansion valve plays a key role in regulating refrigerant flow by restricting its passage, which causes a pressure drop. This pressure change triggers the phase shift from liquid to a low-pressure, cold mixture, essential for heat absorption. Proper control of this process guarantees your heat pump operates efficiently and maintains the right temperature conditions. Additionally, ensuring the valve functions correctly can prevent issues like refrigerant leakage, that might compromise system performance. The pressure drop also influences the phase shift, which is critical for the refrigeration cycle to work effectively. Given the importance of safety and system integrity, ongoing monitoring of AI behavior in related control systems can help identify potential malfunctions early. Furthermore, the celebrity transformations seen in some public figures highlight the importance of adaptability and maintenance in complex systems like heat pumps.

Pressure Regulation Mechanism

The expansion valve or restriction device plays a crucial role in controlling the flow of refrigerant within the heat pump cycle. It creates a high-pressure drop, lowering the refrigerant’s pressure and temperature before it enters the evaporator. This pressure regulation ensures the refrigerant can absorb heat effectively. The device precisely meters refrigerant flow, preventing flooding or starvation of the evaporator. Its size and type influence the pressure differential and flow rate, enhancing system performance. As refrigerant passes through the expansion valve, it rapidly expands and cools, becoming a low-pressure, low-temperature mixture. Proper pressure regulation by the expansion device is essential for maintaining efficiency and avoiding issues. Key points include:

- Maintains ideal refrigerant flow

- Creates necessary pressure drop

- Ensures proper phase change

- Prevents system malfunctions

- Adjusts based on system needs

- GMC tuning techniques and modifications can optimize system performance and efficiency. Additionally, the design of the expansion device impacts the overall reliability and longevity of the heat pump system. Proper selection and maintenance of the pressure regulation mechanism are vital for sustained optimal operation. Regular inspection and adjustment of the expansion valve can help prevent system failures caused by improper refrigerant flow or pressure imbalances. Understanding credit card security measures is also essential for protecting sensitive information in modern payment systems.

Phase Change Initiation

A restriction device, such as an expansion valve, triggers a rapid pressure drop in the refrigerant, causing it to cool sharply before reaching the evaporator. This pressure drop initiates the phase change process, transforming the high-pressure liquid into a low-pressure, subcooled mixture of liquid and vapor. As the refrigerant enters the evaporator, its temperature is now below the surrounding environment, allowing it to absorb heat efficiently. The shift from a high-pressure liquid to a low-pressure mixture is essential for the cycle’s operation, as it prepares the refrigerant for effective heat absorption. Proper regulation of this pressure drop ensures the refrigerant undergoes the correct phase change at the right moment, maintaining system efficiency and facilitating continuous heat transfer in the heat pump cycle.

Flow Control Function

Understanding how the expansion valve or restriction device functions helps you grasp its essential role in controlling refrigerant flow. This component creates a pressure drop that transforms high-pressure liquid refrigerant into a low-pressure, cold mixture. By regulating the refrigerant flow into the evaporator, it guarantees ideal heat absorption. The rapid cooling caused by this pressure drop allows the refrigerant to absorb heat efficiently. Maintaining precise pressure and flow prevents system issues and protects the compressor. Different types of restriction devices, like capillary tubes and thermostatic expansion valves, are chosen based on system needs.

- Creates a pressure drop to lower refrigerant pressure

- Controls refrigerant flow rate into the evaporator

- Ensures rapid refrigerant cooling

- Prevents compressor damage by regulating pressure

- Adapts to system size with various restriction devices

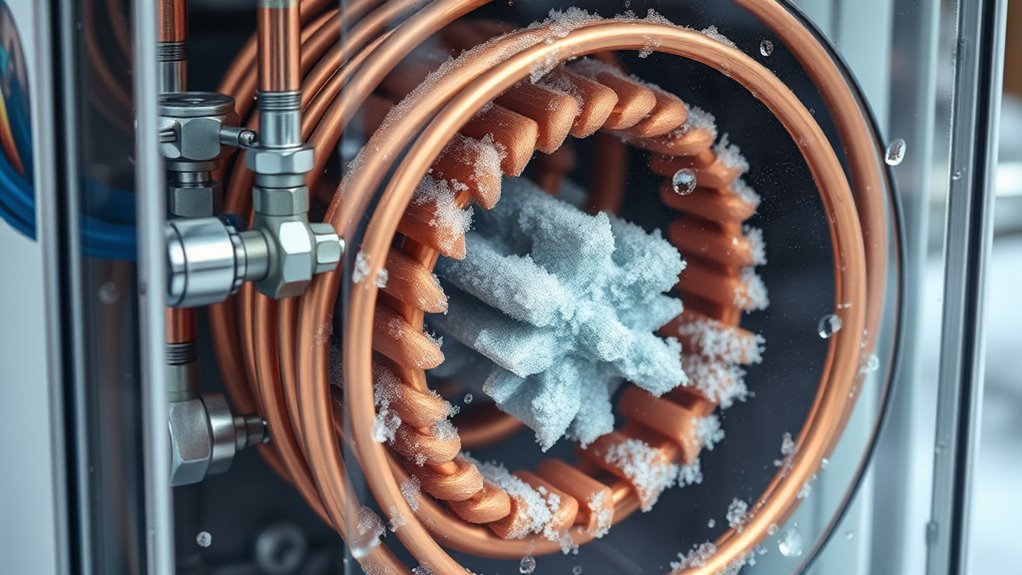

The Evaporator’s Role in Absorbing Heat From Sources

In a heat pump’s refrigeration cycle, the evaporator plays a essential role by absorbing heat from its source—be it air, water, or ground. Inside the evaporator, the refrigerant is in a low-pressure liquid state that boils or vaporizes as it takes in heat from the environment. This process of heat absorption causes the refrigerant to turn into a low-pressure, low-temperature vapor, which then moves to the compressor for further processing. The effectiveness of heat absorption depends on the temperature difference between the source environment and the refrigerant’s evaporating temperature. Proper design of the evaporator ensures maximum surface area and airflow, optimizing heat transfer from the source to the refrigerant. This efficient heat absorption is essential for the overall performance of the heat pump.

The Phase Changes of Refrigerant and Their Significance

The phase changes of refrigerant are at the heart of how heat pumps move heat efficiently. When refrigerant absorbs heat in the evaporator, it changes from liquid to vapor at constant temperature and pressure, enabling effective heat transfer. During condensation, the vapor releases heat as it turns back into a high-pressure liquid in the condenser. These phase changes are vital because they allow the refrigerant to transfer heat between sources and surroundings seamlessly.

- The evaporator absorbs heat during vaporization

- The refrigerant transitions from liquid to vapor at constant conditions

- In the condenser, vapor condenses back to liquid, releasing heat

- Phase changes enable efficient heat transfer in the cycle

- Controlled pressure and temperature guarantee maximum performance

Reversing the Cycle for Heating and Cooling Modes

Reversing the cycle allows heat pumps to switch easily between heating and cooling modes, providing flexible climate control year-round. The key component enabling this switch is the reversing valve, which changes the refrigerant flow direction. In heating mode, the refrigerant absorbs heat from outside air or ground and delivers it indoors. During cooling, the refrigerant flow reverses, removing heat from inside and expelling it outside. The reversing valve directs refrigerant through either the indoor coil as the evaporator for heating or the outdoor coil for cooling, depending on the selected mode. This seamless changeover happens with a simple control switch, making the system versatile. The refrigerant’s pressure and phase changes adapt to each mode, ensuring efficient heating or cooling based on the source and destination temperature differences.

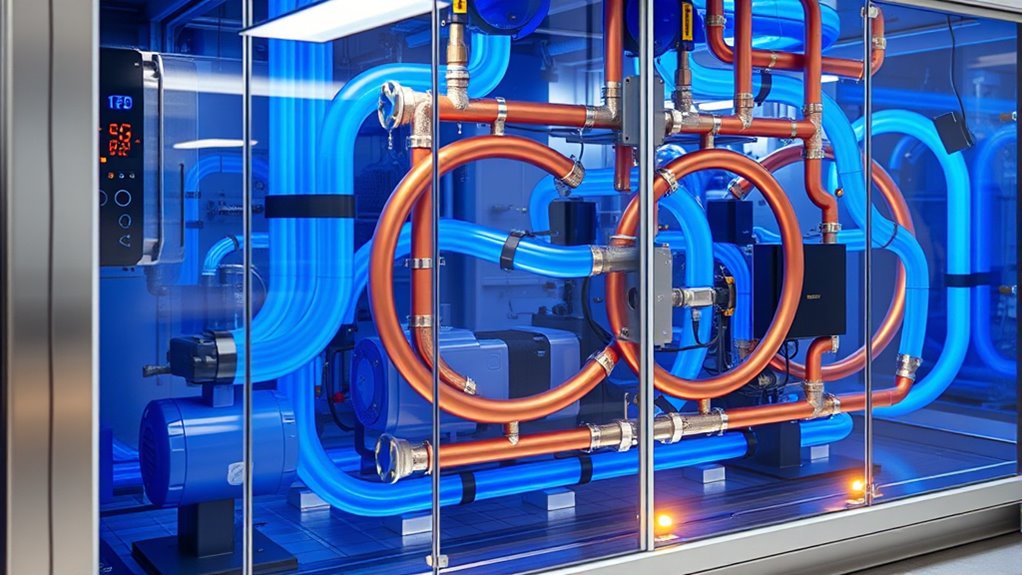

Enhancing Efficiency With Advanced System Designs

Advanced system designs considerably boost the efficiency of heat pumps by incorporating features like two-stage or variable-speed compressors, which fine-tune temperature regulation while reducing energy use. These innovations allow your system to adapt dynamically, saving power during lighter loads. You benefit from variable-speed fans that adjust airflow precisely, enhancing heat exchange. Enhanced heat exchangers with larger surfaces and better fin designs improve heat transfer, increasing efficiency. Smart controls and sensors play a vital role by continuously monitoring conditions and adjusting system parameters to minimize waste. This combination of advanced components ensures your heat pump operates at its best, especially during fluctuating temperatures.

- Variable-speed fans optimize airflow

- High-efficiency heat exchangers boost heat transfer

- Smart controls enable precise regulation

- Two-stage compressors improve load management

- Regular maintenance maximizes system benefits

Frequently Asked Questions

How Does a Heat Pump Refrigeration Cycle Work?

You operate a heat pump by using a refrigeration cycle that transfers heat between indoors and outdoors. The cycle compresses refrigerant vapor, increasing its temperature and pressure, then releases heat through condensation. It’s reversed during heating, pulling heat from outside air. The refrigerant absorbs heat at low pressure, gets compressed, and then releases heat at high pressure, making your home warm efficiently with minimal energy use.

What Is the Relationship Between a Refrigerator and a Heat Pump?

You can see that both refrigerators and heat pumps use the vapor compression cycle to transfer heat. A refrigerator removes heat to cool its interior, while a heat pump can switch modes to either heat or cool a space. They share core components and refrigerants, but heat pumps have a reversing valve that allows them to alternate between heating and cooling, making them more versatile.

What Does Refrigerant Do in a Heat Pump?

Did you know heat pumps can be up to 300% efficient? The refrigerant in your heat pump plays a crucial role: it absorbs heat from the outside air or ground when it evaporates, then releases that heat indoors as it condenses. You control its flow and pressure, enabling your heat pump to effectively transfer heat, keeping your home warm or cool as needed.

How Is the Refrigeration Cycle Reversed in a Heat Pump?

You might wonder how the refrigeration cycle reverses in a heat pump. When needed, the four-way reversing valve switches the flow of refrigerant, changing the roles of the indoor and outdoor coils. This switch allows the evaporator to act as a condenser and vice versa, enabling heat transfer in either direction. The process is automatically controlled by a thermostat, making switching seamless based on your heating or cooling needs.

Conclusion

Understanding the refrigeration cycle reveals how heat pumps efficiently transfer heat for your comfort. Did you know that modern heat pumps can reduce energy consumption by up to 50% compared to traditional heating systems? By mastering thermodynamics and optimizing key components, you can enjoy reliable heating and cooling while saving money and reducing environmental impact. Embrace this technology, and you’ll not only stay comfortable but also contribute to a greener planet.