Did you know that improving the efficiency of the refrigeration cycle in heat pumps can significantly increase their overall performance?

In this article, we will explore various ways to transform your heat pumps by enhancing their refrigeration cycle efficiency.

From understanding the role of compressors to exploring innovative evaporator designs, we will provide you with valuable insights and practical tips.

Join us on this journey to maximize the efficiency of your heat pumps and enjoy superior comfort and energy savings.

Key Takeaways

- Different types of heat pumps, such as air-source, ground-source, and water-source, offer options for maximizing energy efficiency.

- Factors like proper sizing, insulation, refrigerant amount, airflow, and regular maintenance can affect the efficiency of the refrigeration cycle in heat pumps.

- Optimizing refrigeration cycle efficiency in residential heat pumps can be achieved through variable speed compressors, advanced control algorithms, heat exchanger design, and insulation of refrigerant lines.

- Enhancing refrigeration cycle efficiency in industrial heat pumps involves techniques like optimizing heat exchange, advanced controls, improved compressor technology, and minimizing leaks.

Types of Heat Pumps and Their Refrigeration Cycle Efficiency

As we explore the types of heat pumps and their refrigeration cycle efficiency, it’s important to understand their different characteristics and how they contribute to overall energy savings.

When it comes to energy efficient heat pump models, there are several options available in the market. One such model is the air-source heat pump, which extracts heat from the outdoor air and transfers it indoors to heat the space. This type of heat pump can provide significant energy savings compared to traditional heating systems.

Another type is the ground-source heat pump, also known as a geothermal heat pump, which extracts heat from the ground and uses it to heat or cool a building. These heat pumps are highly efficient and have a minimal environmental impact, as they rely on the stable temperature of the ground.

Factors Affecting Refrigeration Cycle Efficiency in Heat Pumps

Our understanding of the factors influencing refrigeration cycle efficiency in heat pumps is essential for optimizing their performance and energy savings. To achieve this, we must consider the following:

- Heat pump size: Properly sizing the heat pump ensures that it operates efficiently and meets the heating or cooling demands of the space.

- Insulation: Adequate insulation reduces the amount of heat transfer between the indoor and outdoor environments, improving the heat pump’s efficiency.

- Refrigerant charge: The correct amount of refrigerant is crucial for efficient heat transfer and operation of the heat pump.

- Airflow: Proper airflow across the evaporator and condenser coils ensures efficient heat exchange and reduces energy consumption.

- Maintenance: Regular maintenance, including cleaning coils and replacing filters, keeps the heat pump operating at peak efficiency.

By optimizing energy usage and reducing costs through these factors, we can enhance the refrigeration cycle efficiency of heat pumps.

This sets the stage for the subsequent section on optimizing the refrigeration cycle efficiency for residential heat pumps.

Optimizing the Refrigeration Cycle Efficiency for Residential Heat Pumps

When it comes to optimizing the refrigeration cycle efficiency for residential heat pumps, there are several improvements that can be made. These improvements can have a significant impact on the overall performance and energy efficiency of the heat pump system.

Cycle Efficiency Improvements

To improve the cycle efficiency of residential heat pumps, we can optimize the refrigeration cycle. By implementing the following strategies, we can achieve significant improvements in cycle efficiency measurements and reduce energy consumption:

- Utilize variable speed compressors to match the heat pump’s output with the heating or cooling load.

- Implement advanced control algorithms that optimize the operation of the heat pump based on real-time conditions.

- Enhance the heat exchanger design to maximize heat transfer and minimize pressure drop.

- Improve the insulation of the refrigerant lines to minimize heat loss during operation.

- Regularly maintain and clean the heat pump components to ensure optimal performance.

By implementing these optimizations, we can expect a substantial impact on the overall efficiency of residential heat pumps.

These improvements can result in reduced energy consumption and lower operating costs, ultimately benefiting homeowners and the environment alike.

In the subsequent section, we’ll explore the specific impact of these optimizations on residential heat pumps.

Impact of Optimization?

Implementing optimization techniques for the refrigeration cycle efficiency of residential heat pumps can have a significant impact on their overall performance.

As technology advancements continue to enhance the capabilities of heat pumps, optimizing their refrigeration cycle efficiency becomes crucial in maximizing their potential. By fine-tuning the various components and parameters of the refrigeration cycle, heat pumps can achieve higher energy efficiency, better temperature control, and reduced operating costs.

Case studies of successful optimization provide evidence of the tangible benefits that can be achieved through this approach. For example, one study demonstrated a 15% improvement in energy efficiency by implementing optimized cycle parameters. Another case study showcased a significant reduction in maintenance and repair costs due to improved system reliability.

These examples highlight the positive impact that optimization can have on the performance and operational costs of residential heat pumps.

Industrial Heat Pumps: Enhancing Refrigeration Cycle Efficiency for Higher Performance

When it comes to industrial heat pumps, enhancing refrigeration cycle efficiency is crucial for achieving higher performance.

To achieve this, various energy-saving techniques can be employed, such as optimizing heat exchange, reducing pressure losses, and minimizing leaks.

Additionally, performance optimization methods, including advanced controls and system monitoring, can be implemented to ensure optimal operation.

Furthermore, enhanced heat pump designs, such as improved compressor technology and heat exchanger configurations, can further enhance the refrigeration cycle efficiency, resulting in improved overall performance.

Energy-Saving Techniques

We can enhance the efficiency of our industrial heat pumps by implementing energy-saving techniques to achieve higher performance in the refrigeration cycle. By utilizing these techniques, we can reduce energy consumption and save costs while still maintaining optimal performance.

Here are some energy-saving techniques and maintenance strategies to consider:

- Regularly clean and maintain heat exchangers to improve heat transfer efficiency.

- Install variable speed drives to match the heat pump’s output with the actual demand, reducing energy wastage.

- Optimize the refrigerant charge to ensure the system operates at its peak efficiency.

- Insulate pipes and equipment to minimize heat loss and increase energy efficiency.

- Implement a preventive maintenance program to detect and address issues before they become major problems, ensuring the system operates at its highest efficiency.

Performance Optimization Methods

By optimizing the performance of our industrial heat pumps, we can enhance the efficiency of the refrigeration cycle for higher performance. To achieve this, it’s essential to conduct a thorough performance analysis of the heat pumps. This analysis involves evaluating various parameters such as pressure, temperature, and flow rates throughout the cycle. By carefully analyzing these parameters, we can identify any inefficiencies or areas for improvement in the system.

Once the performance analysis is complete, we can implement control strategies to optimize the heat pump’s operation. These strategies may include adjusting setpoints, optimizing compressor operation, or implementing advanced control algorithms. By fine-tuning the system’s control strategies, we can ensure that the heat pump operates at its peak efficiency under varying operating conditions.

Furthermore, it’s crucial to continuously monitor and analyze the heat pump’s performance to identify any deviations or anomalies. This allows for timely corrective actions to be taken, ensuring that the system operates at its optimum efficiency and performance.

Enhanced Heat Pump Designs

To enhance the refrigeration cycle efficiency for higher performance, we can explore enhanced heat pump designs that incorporate innovative technologies and advanced components. These designs aim to maximize the heat pump’s performance by improving its efficiency and effectiveness.

Here are some key features of enhanced heat pump designs:

-

Variable-speed compressors: These allow the heat pump to adjust its speed based on the heating or cooling demand, resulting in better energy utilization and enhanced heat pump performance.

-

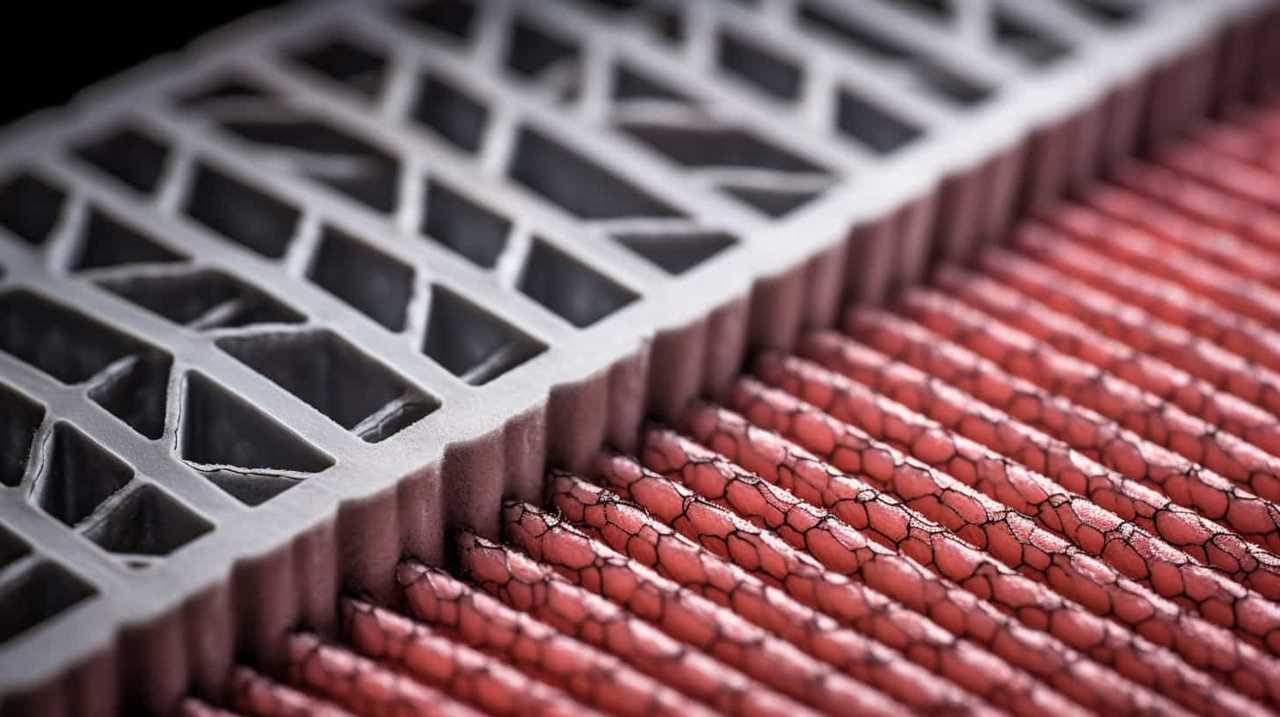

Enhanced heat exchangers: By optimizing the design and materials used in the heat exchangers, heat transfer can be improved, leading to increased efficiency and better overall performance.

-

Advanced control systems: These systems utilize intelligent algorithms and sensors to monitor and optimize the heat pump’s operation, ensuring optimal performance and energy savings.

-

Integration with renewable energy sources: By combining heat pumps with renewable energy technologies like solar panels or geothermal systems, the overall efficiency and performance of the heat pump can be further enhanced.

-

Heat recovery systems: These systems capture waste heat generated by the heat pump and repurpose it for other applications, increasing the overall efficiency of the system.

Understanding the Role of Compressors in Improving Refrigeration Cycle Efficiency

Compressors play a crucial role in increasing the efficiency of the refrigeration cycle. By understanding how compressor technology can reduce energy consumption, we can better serve our audience in improving their heat pump systems.

Compressors work by compressing the refrigerant gas, raising its temperature and pressure. This high-pressure gas then flows through the condenser, where it releases heat and condenses into a liquid. The liquid refrigerant then passes through an expansion valve, which reduces its pressure and temperature. Finally, the low-pressure refrigerant enters the evaporator, where it absorbs heat from the surroundings and evaporates back into a gas.

It’s important to note that the efficiency of the refrigeration cycle is directly affected by the performance of the compressor. By utilizing advanced compressor technology, such as variable speed compressors or scroll compressors, we can optimize energy consumption and improve the overall efficiency of the system.

Innovations in Evaporator Design for Enhanced Refrigeration Cycle Efficiency

Our team has discovered innovative advancements in evaporator design that can greatly enhance refrigeration cycle efficiency. These evaporator coil innovations, combined with energy-saving techniques, offer significant benefits for heat pumps and other refrigeration systems.

Here are some key features of these advancements:

-

Enhanced heat transfer surfaces: New evaporator designs incorporate advanced materials and surface treatments to maximize heat transfer efficiency, allowing for faster cooling and improved energy efficiency.

-

Optimized refrigerant flow: Innovations in evaporator design optimize the flow of refrigerant through the coil, reducing pressure drop and enhancing overall system performance.

-

Improved coil geometry: Evaporators with redesigned coil geometries provide better air distribution and heat exchange, resulting in more uniform cooling and reduced energy consumption.

-

Enhanced defrosting mechanisms: New evaporator designs include improved defrosting mechanisms, minimizing frost buildup and ensuring efficient operation even in low-temperature environments.

-

Intelligent controls: Advanced evaporator designs incorporate intelligent controls that optimize system operation based on real-time conditions, further improving energy efficiency.

These evaporator coil innovations, coupled with energy-saving techniques, offer significant advancements in refrigeration cycle efficiency, resulting in reduced energy consumption and lower operating costs for heat pumps and other refrigeration systems.

Condenser Upgrades: Boosting Refrigeration Cycle Efficiency in Heat Pumps

We have identified key condenser upgrades that can significantly boost refrigeration cycle efficiency in heat pumps. Upgrading the condenser materials and optimizing the condenser sizing are two effective ways to improve the overall performance of heat pumps.

Condenser materials play a crucial role in heat pump efficiency. Using high-quality materials with excellent heat transfer properties can enhance the heat exchange process and reduce energy consumption. Copper and aluminum are commonly used due to their excellent thermal conductivity and corrosion resistance.

Optimizing the condenser sizing is another important factor in maximizing efficiency. A properly sized condenser ensures that the heat transfer process is efficient and effective. Undersized condensers can lead to reduced heat transfer efficiency, while oversized condensers can result in unnecessary energy consumption.

To summarize, upgrading condenser materials and optimizing condenser sizing are practical solutions for boosting refrigeration cycle efficiency in heat pumps. By implementing these upgrades, heat pump systems can provide more efficient and reliable cooling or heating, serving the needs of users effectively.

| Condenser Upgrade | Benefits | Considerations |

|---|---|---|

| Upgrading Materials | – Enhanced heat transfer |

- Reduced energy consumption | – Cost of materials

- Compatibility with existing system |

| Optimizing Sizing | – Improved heat transfer efficiency - Energy savings | – Proper calculation of heat load

- Consideration of space constraints |

Exploring Expansion Valve Options for Improved Refrigeration Cycle Efficiency

To maximize refrigeration cycle efficiency in heat pumps, we can explore different expansion valve options. The expansion valve plays a crucial role in regulating the flow of refrigerant and controlling the pressure drop across the system. Here are some factors to consider when selecting an expansion valve:

-

Expansion valve type: There are various types of expansion valves available, including thermostatic expansion valves (TXV), electronic expansion valves (EEV), and capillary tubes. Each type has its advantages and disadvantages, so careful consideration is needed.

-

Refrigerant compatibility: Different expansion valves are designed to work with specific refrigerants. It’s important to select an expansion valve that’s compatible with the chosen refrigerant to ensure optimal performance and efficiency.

-

Capacity range: Expansion valves come in different sizes and capacity ranges. It’s essential to choose an expansion valve that matches the heat pump’s cooling and heating capacity requirements.

-

Pressure drop: The expansion valve should be selected based on the desired pressure drop across the system. A balanced pressure drop ensures efficient heat transfer and prevents system inefficiencies.

-

Energy efficiency: Some expansion valves are designed to improve energy efficiency by providing better control over the refrigerant flow. These energy-efficient options can contribute to overall system performance and reduce energy consumption.

By carefully considering these factors and selecting the right expansion valve, heat pump systems can achieve improved refrigeration cycle efficiency.

The expansion valve selection, along with the impact of refrigerant choice, plays a significant role in optimizing heat pump performance and ensuring energy-efficient operation.

Maintenance Tips to Maximize Refrigeration Cycle Efficiency in Heat Pumps

To ensure maximum refrigeration cycle efficiency in heat pumps, it’s important to regularly perform maintenance tasks. Heat pump maintenance plays a crucial role in optimizing the refrigeration cycle and ensuring the system operates at peak performance.

One key maintenance task is regularly cleaning or replacing air filters. Clogged filters restrict airflow, reducing the heat pump’s efficiency.

It’s also essential to inspect and clean the outdoor coil to remove any dirt or debris that may hinder heat transfer.

Checking and lubricating fan motors, as well as inspecting and tightening electrical connections, can help prevent any electrical issues that may impact the heat pump’s performance.

Additionally, regular maintenance should include inspecting and cleaning the condensate drain to prevent blockages.

Frequently Asked Questions

How Can I Determine the Refrigeration Cycle Efficiency of Different Types of Heat Pumps?

To determine the refrigeration cycle efficiency of different types of heat pumps, we can compare their performance. By analyzing their energy consumption and heat transfer rates, we can assess which heat pumps are more efficient.

What Are the Most Important Factors That Affect the Refrigeration Cycle Efficiency in Heat Pumps?

Factors that affect refrigeration cycle efficiency in heat pumps include proper sizing, regular maintenance, and use of advanced techniques. These factors ensure optimal performance and energy savings, making a significant difference in the long run.

Are There Any Specific Techniques or Technologies That Can Be Used to Optimize the Refrigeration Cycle Efficiency for Residential Heat Pumps?

There are specific techniques and technologies that can optimize the refrigeration cycle efficiency for residential heat pumps. Smart controls and advanced insulation are two key factors that can greatly improve efficiency.

How Can Industrial Heat Pumps Enhance Refrigeration Cycle Efficiency for Higher Performance?

Industrial heat pump applications enhance refrigeration cycle efficiency, allowing for higher performance in commercial settings. By optimizing heat transfer, improving compressor technology, and utilizing advanced control systems, we can achieve superior heat pump performance.

What Role Do Compressors Play in Improving Refrigeration Cycle Efficiency, and What Are Some Innovative Approaches to Compressor Design?

Compressor efficiency is crucial in improving refrigeration cycle efficiency. Innovative approaches to compressor design can optimize performance. By enhancing compression processes, we can achieve higher energy savings and overall system effectiveness.

Conclusion

In conclusion, optimizing the refrigeration cycle efficiency of heat pumps is crucial for maximizing their performance. Factors such as the type of heat pump, compressor technology, evaporator design, condenser upgrades, and expansion valve options all play a significant role in enhancing efficiency.

By implementing innovative techniques and regular maintenance, heat pump users can ensure the longevity and effectiveness of their systems. Remember, a well-maintained and efficient refrigeration cycle is key to achieving superior heat pump performance.