Are you ready to utilize your skills in servicing commercial heat pumps? We offer all the necessary information to help your unit run efficiently.

In this article, we’ll cover the importance of regular maintenance, key components to inspect, cleaning and airflow optimization, lubrication and belt replacement, refrigerant levels and leak detection, electrical connections and controls, and troubleshooting common issues.

Let’s dive in and become experts in maintaining our heat pumps!

Key Takeaways

- Regular maintenance is essential for optimal performance and longevity of commercial heat pumps.

- Professional maintenance helps identify and address minor issues before they become major problems.

- Proper refrigerant levels are crucial for efficient operation and energy consumption.

- Regular inspections and leak detection methods are important for identifying and repairing refrigerant leaks.

The Importance of Regular Maintenance

Regular maintenance is essential for ensuring the optimal performance and longevity of our commercial heat pumps. The importance of scheduling regular maintenance can’t be overstated.

By adhering to a strict maintenance schedule, we can identify and address minor issues before they escalate into major problems that could potentially disrupt the functioning of our heat pumps. Regular maintenance also allows us to maximize the energy efficiency of our systems, reducing operational costs and minimizing environmental impact.

Additionally, the benefits of professional maintenance can’t be ignored. Trained technicians have the expertise and equipment to thoroughly inspect and clean our heat pumps, ensuring that they operate at peak efficiency. They can also provide valuable advice on proper maintenance practices, helping us extend the lifespan of our equipment and avoid costly repairs.

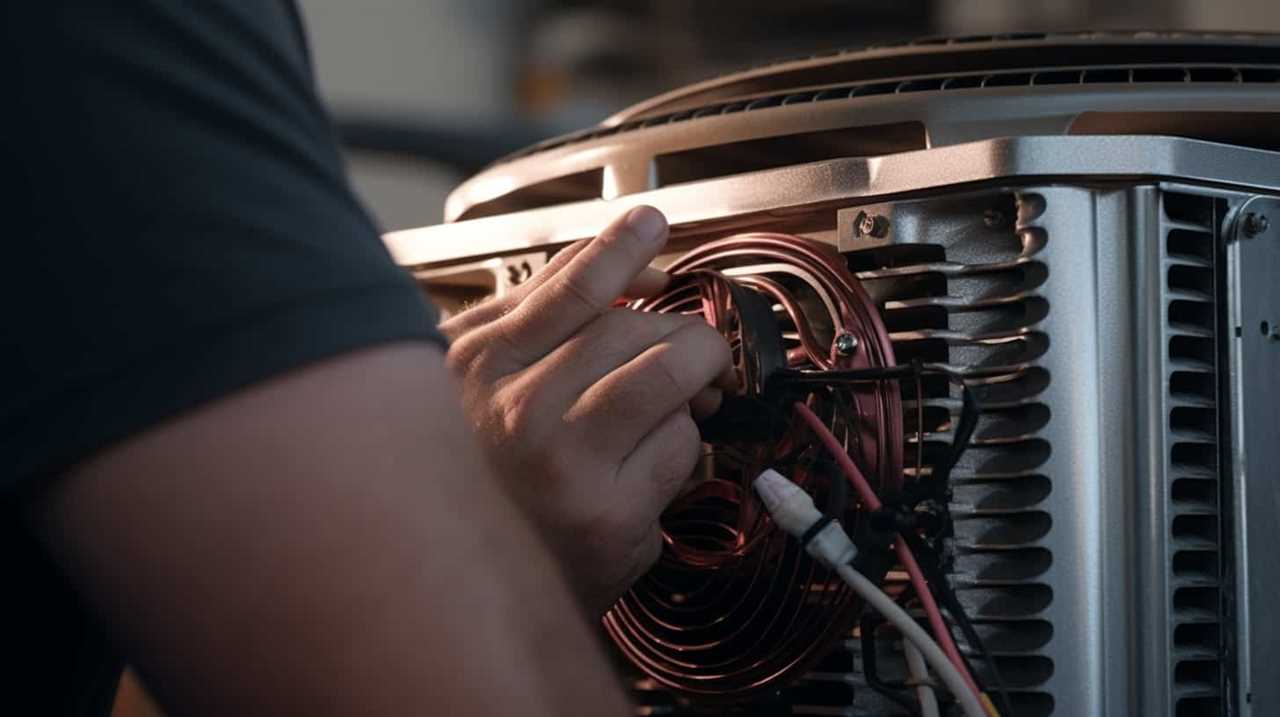

Key Components to Inspect

When inspecting our commercial heat pumps, we should pay close attention to the compressor and the evaporator coil. The compressor is responsible for compressing the refrigerant and pumping it through the system, while the evaporator coil allows the refrigerant to absorb heat from the air. However, it is also important to inspect other key components to ensure optimal performance and energy efficiency.

One crucial aspect to inspect is the insulation. Insulation plays a vital role in preventing heat transfer and maintaining the desired temperature within the system. Any signs of wear or damage should be addressed promptly to avoid energy loss.

Another component that requires regular inspection is the air filter. A clean and properly functioning air filter is essential for maintaining good indoor air quality and preventing dust and debris from clogging the system. Regular filter replacement is necessary to ensure efficient airflow and prevent strain on the heat pump.

To emphasize the importance of insulation inspection and filter replacement, the following table provides a summary:

| Component | Importance | Action Required |

|---|---|---|

| Insulation | Prevents heat transfer and maintains temperature | Inspect for wear or damage |

| Air Filter | Maintains indoor air quality and prevents clogging | Regular replacement to ensure efficiency |

Cleaning and Airflow Optimization

To ensure optimal performance and energy efficiency, we need to clean the heat pump components and optimize airflow. One important maintenance task is air filter replacement. The air filter prevents dust, dirt, and debris from entering the heat pump and affecting its performance. Over time, the filter gets clogged and needs to be replaced. We recommend checking the air filter at least once a month and replacing it when it appears dirty or every three months, whichever comes first.

Another crucial step in maintaining a heat pump is condenser coil cleaning. The condenser coil is responsible for releasing heat to the outside environment. However, it can become dirty and obstructed by debris such as leaves, grass, and dust. This reduces the heat transfer efficiency and affects the overall performance of the heat pump. It’s important to clean the condenser coil regularly using a soft brush or a vacuum cleaner to remove any accumulated dirt or debris.

Lubrication and Belt Replacement

Before conducting lubrication and belt replacement on a commercial heat pump, we must ensure that the power is turned off and the system is safely disconnected.

Belt tensioning is an essential part of heat pump maintenance as it ensures optimal performance and reduces wear and tear. To properly tension the belt, start by loosening the motor mounting bolts and adjusting the tensioning mechanism. Use a tension gauge to measure the deflection of the belt. Adjust the tension until it falls within the manufacturer’s recommended range.

Lubrication is crucial to reduce friction and extend the life of the heat pump. Using the manufacturer-recommended lubricant, apply a small amount to the bearings and other moving parts. Be careful not to over-lubricate, as excess lubrication can cause damage.

Regular lubrication and proper belt tensioning are vital for maintaining the efficiency and reliability of commercial heat pumps.

Refrigerant Levels and Leak Detection

Maintaining proper refrigerant levels in a commercial heat pump is crucial for its optimal performance. Regular maintenance allows us to detect and address any refrigerant leaks that may occur.

Common sources of refrigerant leaks include damaged or worn-out valves, fittings, and coils. To ensure efficient leak detection, we use specialized tools such as electronic leak detectors, ultraviolet dye, and pressure gauges.

Importance of Regular Maintenance

Regular maintenance of commercial heat pumps is crucial for monitoring and maintaining proper refrigerant levels and detecting any leaks.

Proper refrigerant levels are essential for the efficient operation of a heat pump system. Insufficient refrigerant can lead to decreased cooling or heating performance and increased energy consumption. On the other hand, overcharging the system can cause compressor damage and reduce the overall lifespan of the heat pump.

Detecting leaks is equally important as refrigerant leaks not only lead to decreased system efficiency but also have negative environmental impacts. Professional maintenance ensures that refrigerant levels are checked regularly and any leaks are promptly identified and repaired.

Common Refrigerant Leak Sources

Identifying common refrigerant leak sources is crucial for maintaining proper refrigerant levels and ensuring effective leak detection in commercial heat pump systems. To serve you better, we’ve compiled a list of common refrigerant leak sources for your reference:

-

Faulty connections: Leaks can occur due to loose or damaged connections between refrigerant lines and components. Regularly inspect and tighten these connections to prevent leaks.

-

Aging components: Over time, components such as valves, coils, and fittings can deteriorate, leading to refrigerant leaks. Replace worn-out parts promptly to prevent leaks.

-

Corrosion: Corrosion can cause damage to refrigerant lines and result in leaks. Apply anti-corrosion coatings and inspect for signs of corrosion regularly.

-

Poor installation: Improper installation practices, such as inadequate brazing or improper soldering, can create weak points that may lead to refrigerant leaks. Ensure proper installation techniques are followed.

Understanding these common sources of refrigerant leaks will help you in implementing effective leak prevention and repair techniques.

Now, let’s move on to the next section where we’ll discuss the tools for leak detection.

Tools for Leak Detection

We will discuss the necessary tools and techniques to accurately measure refrigerant levels and detect leaks in commercial heat pump systems.

When it comes to leak detection methods, there are several options available. One commonly used method is the electronic leak detector, which utilizes a heated diode sensor to detect refrigerant leaks.

Another option is ultrasonic leak detection equipment, which uses high-frequency sound waves to identify leaks by detecting the sound produced by escaping refrigerant.

Additionally, dye leak detection methods involve injecting a fluorescent dye into the system, which can then be traced using a UV light to identify the source of the leak.

It’s important to note that regardless of the method chosen, regular maintenance and inspection of commercial heat pump systems are crucial for ensuring optimal performance and reducing the risk of refrigerant leaks.

Electrical Connections and Controls

Sometimes we need to check the electrical connections and controls of the commercial heat pump to ensure proper functioning. When it comes to electrical safety, it’s crucial to follow the necessary precautions.

Here are some troubleshooting techniques to consider:

-

Inspect the power supply: Check if the power is properly connected, and if there are any loose or damaged wires.

-

Test the control panel: Verify if all the buttons and switches are working correctly and if the control panel is displaying accurate information.

-

Examine the sensors: Ensure that the temperature and pressure sensors are clean, calibrated, and providing accurate readings.

-

Verify the circuit board: Inspect the circuit board for any signs of damage or burnt components, and check the connections for any loose wires.

Troubleshooting Common Issues

When troubleshooting common issues with commercial heat pumps, there are three main points to consider: leaking refrigerant solutions, thermostat malfunctioning problems, and poor airflow issues.

Leaking refrigerant can lead to decreased cooling or heating capacity, and it requires identifying and fixing the source of the leak.

Thermostat malfunctions can result in inaccurate temperature readings or failure to activate the heat pump, often requiring recalibration or replacement.

Poor airflow can be caused by dirty filters, blocked vents, or faulty fans, which need to be cleaned or repaired to ensure proper air circulation.

Leaking Refrigerant Solutions

Identifying and addressing leaking refrigerant is crucial for maintaining the efficiency and functionality of commercial heat pumps. Leaks can lead to reduced cooling or heating capacity, increased energy consumption, and potential damage to the system. To effectively detect and prevent refrigerant leaks, the following methods and solutions can be employed:

- Regular inspections using electronic leak detectors or ultraviolet dye can help identify leaks early on.

- Proper installation and maintenance of refrigerant lines, fittings, and connections can prevent leaks from occurring.

- Ensuring that the system is properly charged with refrigerant can minimize the risk of leaks.

- Implementing a proactive leak prevention plan that includes regular maintenance, inspections, and repairs can keep the system running smoothly and efficiently.

By following these leak detection methods and refrigerant leak prevention strategies, you can ensure the longevity and optimal performance of your commercial heat pump.

Now, let’s transition to the subsequent section about ‘thermostat malfunctioning problems’.

Thermostat Malfunctioning Problems

To effectively troubleshoot common thermostat malfunctioning problems, we need to understand the potential causes and solutions. One common issue is thermostat calibration, which can lead to incorrect temperature readings and inefficient heating or cooling. If the thermostat is not calibrated correctly, it may require adjustment or recalibration. Another problem that may arise is a faulty thermostat that needs replacement. This can be due to wear and tear or internal malfunctions. To determine if a thermostat replacement is necessary, it is important to check if the thermostat is unresponsive, has a blank screen, or is not accurately controlling the temperature. By addressing these thermostat malfunctioning problems promptly, HVAC professionals can ensure optimal comfort and energy efficiency for their customers.

| Potential Causes | Solutions |

|---|---|

| Incorrect calibration | Adjust or recalibrate the thermostat |

| Faulty thermostat | Replace the thermostat |

Poor Airflow Issues

We can address poor airflow issues by checking for common causes and implementing appropriate solutions. When troubleshooting poor airflow in a commercial heat pump, there are a few key issues to consider:

-

Airflow restrictions: Inspect the air filters and ensure they’re clean and not obstructed. Additionally, check for any blockages in the ductwork that may be limiting the flow of air.

-

Fan motor malfunction: Test the fan motor to ensure it’s operating properly. If the fan motor isn’t functioning correctly, it may not be able to generate enough airflow.

-

Duct leakage: Examine the ductwork for any leaks or gaps. Leaky ducts can significantly reduce airflow, impacting the overall performance of the heat pump.

-

Improper duct design: Evaluate the duct design to ensure it’s properly sized and configured. Inadequate duct design can lead to restricted airflow and decreased efficiency.

Frequently Asked Questions

How Often Should Commercial Heat Pumps Be Inspected and Maintained?

Regular commercial heat pump maintenance is essential for optimal performance. Inspections should be conducted at least once a year to ensure efficiency and prevent breakdowns. By addressing issues promptly, the benefits of regular maintenance outweigh common challenges faced during upkeep.

What Are the Signs That Indicate a Need for Heat Pump Maintenance?

Signs of heat pump maintenance needs include reduced airflow, strange noises, and fluctuating temperatures. It is important to address these issues promptly to ensure optimal performance and prevent further damage.

Can Heat Pump Maintenance Be Performed by the Building Owner or Does It Require Professional Assistance?

Heat pump maintenance can be performed by the building owner, but it is recommended to seek professional assistance. The owner’s role includes regular filter cleaning and inspection, while professionals can handle more complex tasks like refrigerant checks and electrical component maintenance.

Are There Any Specific Safety Precautions to Consider While Performing Heat Pump Maintenance?

Safety precautions are essential when performing heat pump maintenance. We follow specific guidelines to ensure our well-being and the proper functioning of the equipment. Our team prioritizes safety to deliver high-quality service to our customers.

What Are the Potential Consequences of Neglecting Regular Heat Pump Maintenance?

Neglecting regular heat pump maintenance can lead to serious consequences. Regular maintenance is important to ensure optimal performance and efficiency, prevent breakdowns, extend the lifespan of the equipment, and reduce energy costs.

Conclusion

In conclusion, regular maintenance of commercial heat pumps is crucial for their optimal performance. By inspecting key components, optimizing airflow, lubricating and replacing belts, checking refrigerant levels, and ensuring proper electrical connections and controls, potential issues can be identified and resolved promptly.

Interestingly, studies have shown that proper maintenance can increase the efficiency of heat pumps by up to 25%, resulting in significant energy savings for businesses. Therefore, investing in regular maintenance is essential for both the longevity and cost-effectiveness of commercial heat pump systems.