Common issues that affect thermal energy transfer in heat pumps include refrigerant leaks, compressor problems, frost buildup, dirty coils, and airflow restrictions. Leaks and frosting reduce heat exchange efficiency, while compressor and electrical failures hinder system performance. Dirty filters and debris block airflow, further decreasing efficiency. Proper maintenance, timely repairs, and regular inspections can resolve these problems. Keep exploring to learn more about preventing and fixing these common heat pump issues effectively.

Key Takeaways

- Refrigerant leaks and frost buildup impair heat exchange, reducing efficiency; regular maintenance and leak repairs prevent these issues.

- Compressor malfunctions and electrical failures decrease thermal transfer, requiring electrical inspections and timely repairs.

- Frost on outdoor coils from defrost cycle failures blocks airflow, lowering system performance; sensor testing and control repairs help.

- Dirty filters, clogged coils, and blocked outdoor units hinder airflow, causing freezing or overheating; routine cleaning maintains optimal transfer.

- Incorrect thermostat calibration and faulty sensors disrupt temperature regulation, necessitating recalibration and proper electrical inspections.

Refrigerant Leaks and Their Impact on Heat Transfer

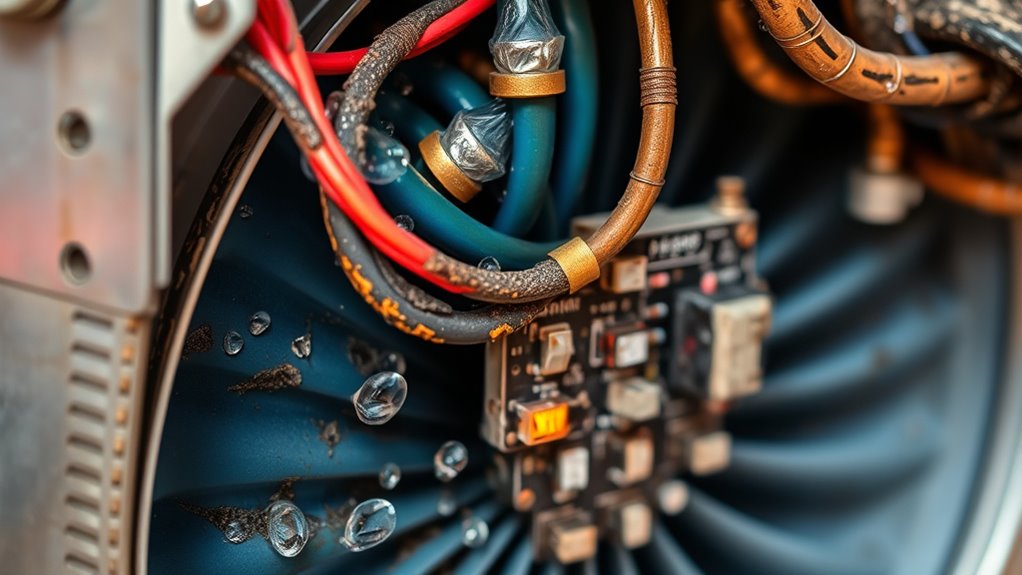

Refrigerant leaks can considerably hinder your heat pump’s ability to transfer thermal energy effectively. When refrigerant leaks occur, the reduced refrigerant levels impair heat exchange, lowering heat transfer efficiency. This decrease makes your system work harder, decreasing overall heat pump efficiency and leading to poor heating or cooling performance. Signs like ice buildup on coils or hissing sounds indicate a leak, but professional leak detection is essential for accurate diagnosis. Without proper system repair and refrigerant recharge, the leak persists, further compromising thermal energy transfer. Maintaining ideal refrigerant levels ensures efficient heat exchange, preserves system performance, and prevents unnecessary energy consumption. Addressing refrigerant leaks promptly restores proper heat transfer and keeps your heat pump functioning at peak efficiency. Regular maintenance and awareness of refrigerant levels can help prevent future issues and ensure optimal system operation. Additionally, understanding the cooling cycle of heat pumps can aid in diagnosing and fixing transfer inefficiencies. Proper system design also plays a crucial role in minimizing leak risks and optimizing heat transfer efficiency. Being aware of installation standards can further reduce the likelihood of leaks and enhance overall system reliability.

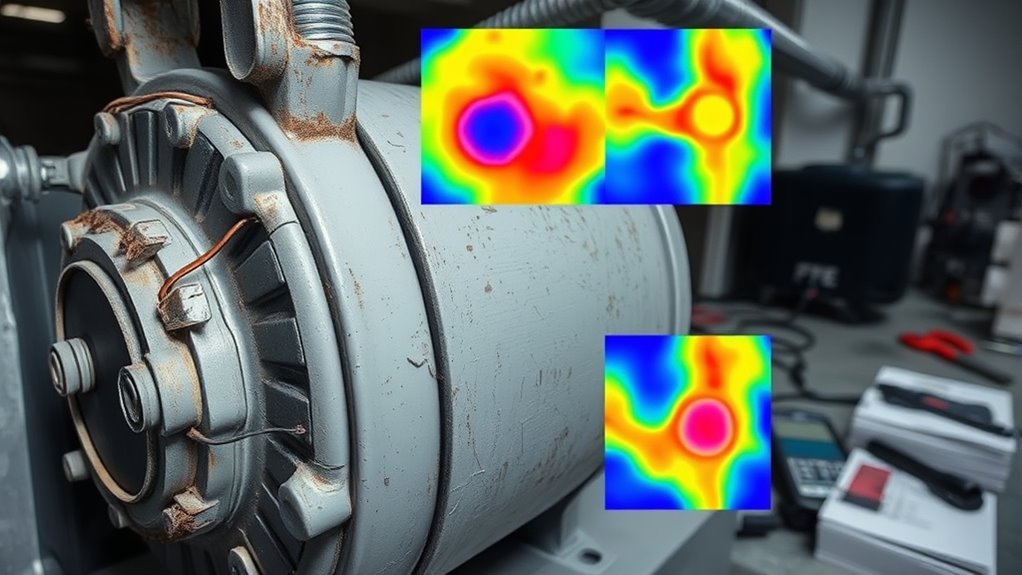

Compressor Malfunctions and System Efficiency Problems

Compressor malfunctions can considerably reduce your heat pump’s efficiency, causing it to blow cold air during heating or fail to start altogether. Signs of compressor failure include loud noises, excessive vibration, and frequent cycling. Common causes include electrical failures, refrigerant leaks, and wear over time, typically around 10-15 years. When the compressor malfunctions, it hampers heat transfer, leading to decreased system performance and increased energy consumption. This not only raises utility bills but also shortens your system’s lifespan. Regular maintenance—such as inspecting electrical connections and refrigerant levels—can help prevent compressor failure. Addressing these issues promptly ensures your system runs smoothly, maintains maximum efficiency, and prolongs its overall performance, minimizing costly malfunctions and maximizing comfort. Additionally, automation in diagnostics and monitoring can help detect early signs of compressor issues before they lead to complete failure. Incorporating preventive measures like routine inspections and timely part replacements can further enhance the system’s longevity.

Defrost Cycle Failures and Frost Buildup

When your heat pump’s outdoor coils develop frost, it can block airflow and reduce efficiency. Failures in the defrost cycle often happen because sensors or control boards malfunction, leaving ice to build up unchecked. This frost buildup hampers heat transfer and causes your system to work harder, increasing energy use. Regular maintenance and proper system installation are essential to prevent these issues and ensure optimal performance. Additionally, advancements in AI-driven diagnostics can help identify and address malfunctions more quickly, minimizing frost-related problems. Proper maintenance practices can also extend the lifespan of your heat pump and improve its resistance to frost buildup. Incorporating advanced defrost technology can further enhance system reliability by improving frost detection and removal efficiency. Staying informed about frost monitoring methods can help in early detection and prevention of severe frost accumulation.

Causes of Defrost Failures

Defrost cycle failures often stem from faulty sensors or control board malfunctions that prevent the system from initiating the defrost mode at the right time. When sensors send incorrect signals or the control board malfunctions, the defrost cycle may not start, leading to frost buildup on outdoor coils. Frost accumulation impairs refrigerant flow and reduces heat transfer efficiency. Proper sensor calibration can help ensure accurate signals and prevent unnecessary defrost cycle issues. Reversing valves can also malfunction; improper operation of reversing valves can hinder refrigerant flow reversal and prevent proper defrosting. Airflow restrictions, dirty coils, or low refrigerant levels further exacerbate frost formation. Regular coil cleaning and sensor testing help guarantee the defrost cycle functions correctly. Addressing control board issues and verifying refrigerant levels are essential steps in preventing defrost failures and maintaining maximum heat pump performance. Additionally, understanding the refrigerant cycle is crucial for diagnosing and correcting issues related to frost buildup and defrost failures. Proper heat transfer is vital for efficient operation, and any disruption can lead to the problems described above. Ensuring that all components operate correctly can also be supported by wireless monitoring systems that alert to potential faults early. Incorporating diagnostic tools can further help identify underlying issues before they cause significant performance drops.

Effects of Frost Buildup

Frost buildup on outdoor coils directly impacts your heat pump’s performance by blocking heat transfer, forcing the system to work harder and consume more energy. When ice accumulates, it hampers heat transfer, reducing efficiency and causing coil freezing. If the defrost cycle fails or defrost controls malfunction, ice formation persists, leading to excessive frost buildup. This ice accumulation prevents proper airflow, further decreasing heat pump efficiency. Low outdoor temperatures and high humidity accelerate frost buildup, especially if frost prevention measures aren’t in place. Regularly cleaning coils and ensuring defrost controls function correctly helps prevent ice formation. When frost persists despite these efforts, it indicates a need for professional diagnosis to address potential defrost cycle failures, restoring proper heat transfer and maintaining system efficiency. Proper heat transfer is essential for maintaining optimal system performance and energy efficiency. Additionally, ensuring that the system’s defrost system is functioning correctly can help prevent such issues from recurring. Regular inspection and maintenance of components that influence frost buildup can also extend the lifespan of your heat pump and improve overall reliability. Addressing issues like defrost cycle failure promptly can prevent costly repairs and ensure consistent operation during cold weather. Recognizing early signs of frost buildup can help mitigate damage and improve the longevity of your heat pump.

Dirty Coils and Restricted Airflow

Have you noticed your heat pump struggling to heat or cool effectively? Dirty coils and restricted airflow are common culprits that hurt system performance. Here’s what you should know:

- Dirty evaporator or condenser coils can reduce heat transfer efficiency by up to 30%, forcing your system to work harder. Regular coil cleaning and replacing air filters every 1-3 months help prevent dirt buildup and ensure proper refrigerant flow. Additionally, proper maintenance of these components is essential for optimal operation. Keeping coils clean also prevents the buildup of debris, which can further obstruct heat transfer processes.

- Airflow blockage from clogged filters or debris in outdoor units hampers airflow, causing coils to freeze or overheat. Proper placement and regular maintenance of airflow pathways can significantly improve system function.

- Upgrading to performance-oriented components, such as high-quality filters or enhanced coil designs, can further improve your heat pump’s efficiency and longevity.

- When coils are coated with dirt, the heat exchange process slows down, reducing overall system efficiency. Maintaining clean coils and clear airflow pathways keeps your heat pump running smoothly.

Thermostat Calibration and Control Issues

Proper thermostat calibration is essential for your heat pump to operate efficiently and maintain consistent comfort. When your thermostat isn’t calibrated correctly, you may encounter control issues that disrupt temperature regulation, causing the system to run excessively or not enough. Faulty wiring or sensor malfunctions can send inaccurate signals, leading to poor temperature accuracy and improper system activation. Upgrading to a digital thermostat with calibration features allows you to easily perform calibration adjustments, ensuring precise temperature detection. Regularly checking and recalibrating your thermostat helps maintain system efficiency and prevents unnecessary wear on components. Addressing calibration issues promptly guarantees your heat pump responds correctly to temperature changes, providing reliable comfort and *ideal* thermal energy transfer.

Blockages and Debris in Ductwork and Outdoor Units

Blockages and debris in ductwork and outdoor units can substantially reduce your heat pump’s efficiency if left unaddressed. These obstructions, like leaves, dirt, and small branches, block airflow around outdoor units, causing system overheating or freezing. Similarly, debris within ductwork restricts airflow, leading to poor heating or cooling and increased energy use. Accumulated dust and mold can also impair indoor air quality. Regular maintenance helps prevent severe blockages that could cause system malfunction or damage. To stay efficient, schedule professional removal of debris and ensure your ductwork and outdoor units are clear. Proper system operation is also essential for maintaining efficiency and preventing issues. Additionally, air quality can deteriorate due to buildup of dust and mold, impacting indoor health. Key issues include:

- Blockages in outdoor units reducing airflow and causing system overheating.

- Debris buildup inside ductwork leading to system freezing.

- Poor indoor air quality from accumulated dust and mold.

- Proper lifestyle practices, such as regular cleaning and inspections, promote optimal system performance and longevity.

Electrical Component Failures Affecting Thermal Transfer

Electrical component failures can markedly disrupt the thermal transfer process in your heat pump. Faulty relays, contactors, or capacitors can interrupt power to crucial heat pump components, reducing efficiency. Short circuits or blown fuses in electrical panels may disable key parts responsible for maintaining proper thermal transfer, leading to system shutdowns. Wiring corrosion or loose connections increase electrical resistance, causing inconsistent operation and lower heat exchange performance. Additionally, issues within the control board or reversing valves can prevent proper switching between heating and cooling modes, impairing thermal energy transfer. These electrical failures compromise your heat pump’s ability to effectively transfer heat, resulting in decreased comfort and higher energy costs. Regular inspection and prompt repairs of electrical components are essential to maintaining ideal thermal transfer and system reliability.

Frequently Asked Questions

What Is the Major Problem With a Heat Pump?

The major problem with a heat pump is refrigerant leaks, which lower efficiency and can damage the compressor. These leaks cause the system to struggle with heat transfer, making it less effective. You might also face issues like faulty reversing valves or electrical failures that disrupt operation. Regular maintenance, including checking for leaks and cleaning filters, helps prevent these problems and keeps your heat pump running smoothly.

How Does a Heat Pump Transfer Thermal Energy?

Ever wondered how a heat pump moves thermal energy? You’re the one who benefits from its clever system. It absorbs heat from the outdoor air through refrigerant-filled coils, even in cold weather. The refrigerant then becomes a gas, is compressed to increase its temperature, and releases heat indoors via condenser coils. When cooling, the process reverses, removing indoor heat. Proper functioning of components guarantees this transfer remains efficient.

What Are the Common Faults of Air Source Heat Pumps?

You should be aware that common faults in air source heat pumps include refrigerant leaks, which lower efficiency and cause ice buildup. Reversing valve issues can make the system blow cold air or fail to switch modes. Dirty filters and blocked outdoor units reduce airflow, impacting performance. Electrical problems, like faulty capacitors, can prevent startup or cause continuous running. Ultimately, defrost cycle malfunctions lead to ice accumulation and decreased efficiency.

What Are Some Symptoms of Restricted Airflow in a Heat Pump System?

You notice your heat pump isn’t warming or cooling as well as it should. You might feel weak or inconsistent airflow from your vents, or see signs like increased indoor humidity or mold. Your outdoor unit could develop ice buildup faster, and your system may work harder, raising energy bills. These symptoms point to restricted airflow, often caused by dirty filters, blocked vents, duct leaks, or debris in the outdoor unit.

Conclusion

By staying attentive to refrigerant leaks, compressor issues, and dirty coils, you can catch problems early. Regular maintenance helps prevent frost buildup and control failures, ensuring efficient heat transfer. When ductwork is clear and electrical parts are functioning, your heat pump performs at its best. Coincidentally, addressing these issues keeps your system running smoothly, saving energy and prolonging its lifespan. Stay proactive, and your heat pump will reliably keep you warm or cool when you need it most.