To improve heat transfer with microchannel condensers, focus on using advanced materials like nanostructured coatings and innovative thermal interface layers that boost conductivity and reduce fouling. Optimize channel shapes and aspect ratios to promote turbulence and maximize surface contact. Employ precise manufacturing techniques such as laser micro-machining for consistent, complex geometries. Modeling tools help identify ideal designs and flow management strategies, ensuring uniform flow and minimal pressure loss—keep exploring for more ways to enhance your system’s performance.

Key Takeaways

- Optimize microchannel geometry, such as aspect ratio and shape, to enhance turbulence and heat transfer efficiency.

- Apply nanostructured surface coatings to reduce fouling and improve thermal contact.

- Use nanofluids with enhanced thermal conductivity to boost heat transfer rates within channels.

- Employ advanced manufacturing techniques like laser micro-machining for precise, complex microchannel designs.

- Incorporate flow management strategies, including manifolds and flow restrictors, to ensure uniform flow and minimize pressure drops.

Material Innovations for Enhanced Thermal Conductivity

Have you ever wondered how material choices can improve the performance of microchannel condensers? Using nanostructured materials can notably boost thermal conductivity, allowing heat to transfer more efficiently. These advanced materials have unique properties due to their tiny structures, which facilitate better heat flow. Incorporating superior thermal interface materials ensures minimal thermal resistance between components, enhancing overall system performance. By selecting these innovative materials, you can reduce temperature gradients and improve heat dissipation. This not only increases the condenser’s efficiency but also extends its lifespan. Material innovations like nanostructured materials and advanced thermal interface materials are transforming microchannel condenser design, making them more effective and reliable in managing heat. Vibrational energy is also an important factor in optimizing heat transfer efficiency. These choices are vital for achieving ideal cooling performance in modern applications.

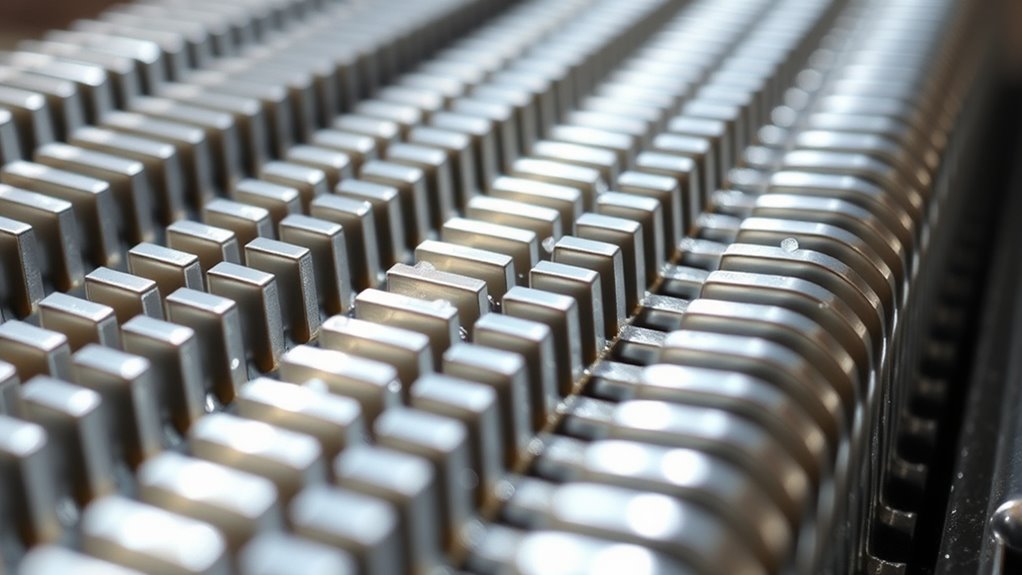

Optimizing Channel Geometry for Improved Heat Transfer

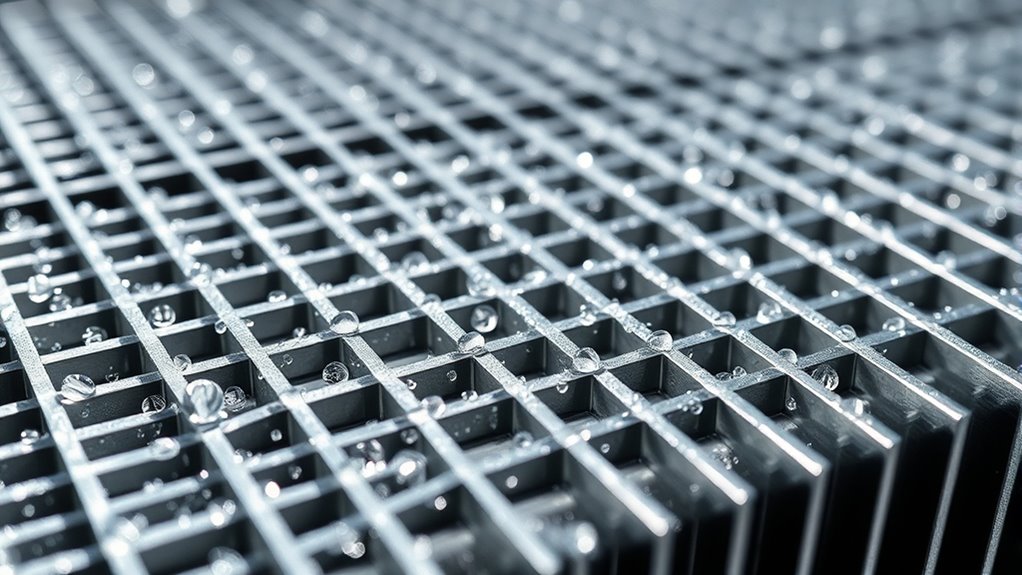

Optimizing the channel geometry in microchannel condensers plays a crucial role in enhancing heat transfer efficiency. Adjusting channel aspect ratios can influence flow dynamics, promoting better fluid contact with heat transfer surfaces. Narrower channels increase surface area, improving thermal performance, but may lead to higher pressure drops. Balancing aspect ratios ensures ideal heat transfer without excessive pumping power. Flow channel shapes also matter; for example, rectangular or trapezoidal designs can promote turbulence, boosting heat transfer coefficients. You should consider how different shapes affect fluid flow and heat exchange. Properly optimized geometries minimize thermal resistance and maximize heat removal. Incorporating self water management systems in condenser design can further improve overall efficiency by maintaining optimal operating conditions. By fine-tuning these parameters, you can markedly improve condenser performance, making your system more energy-efficient and reliable.

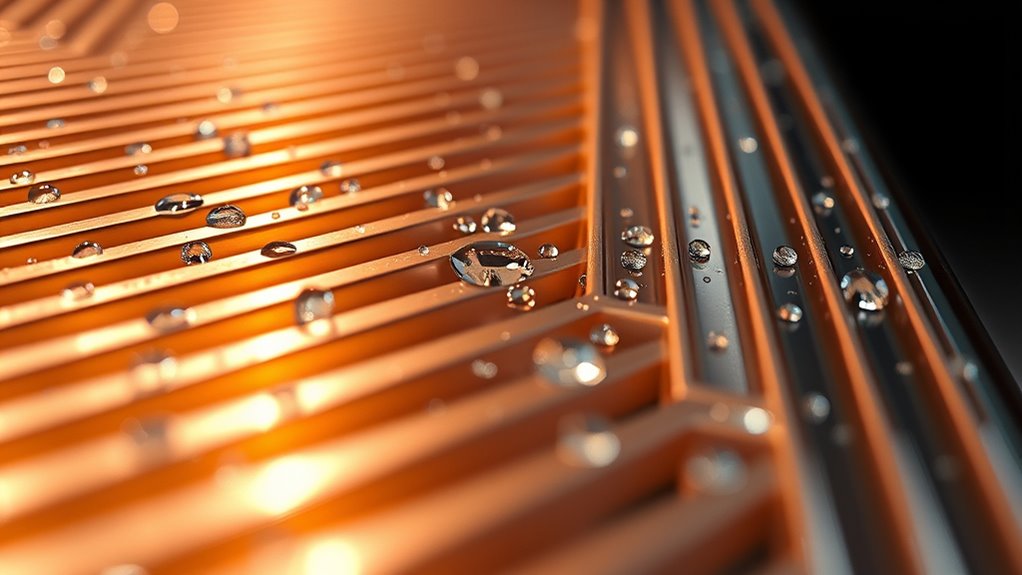

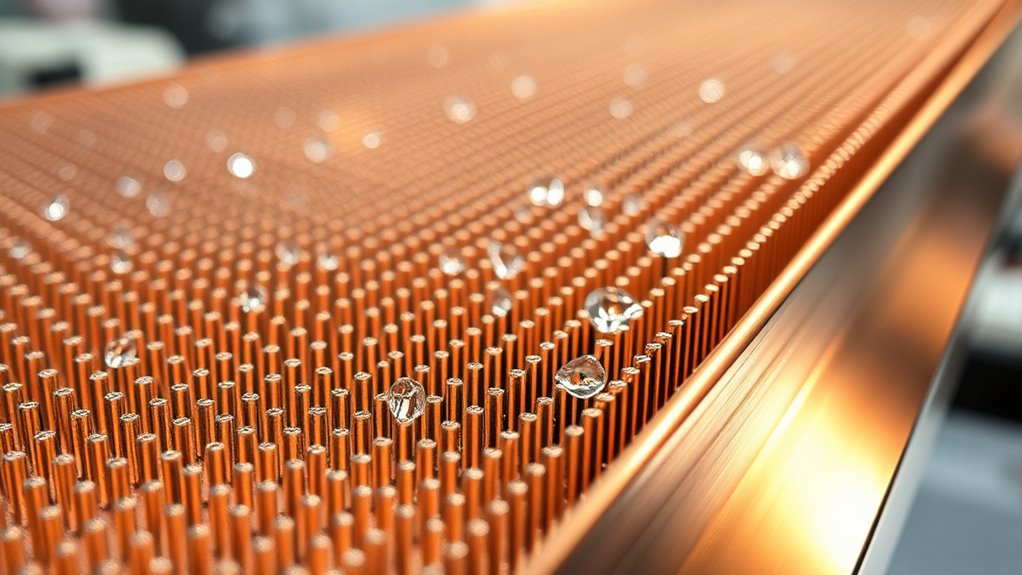

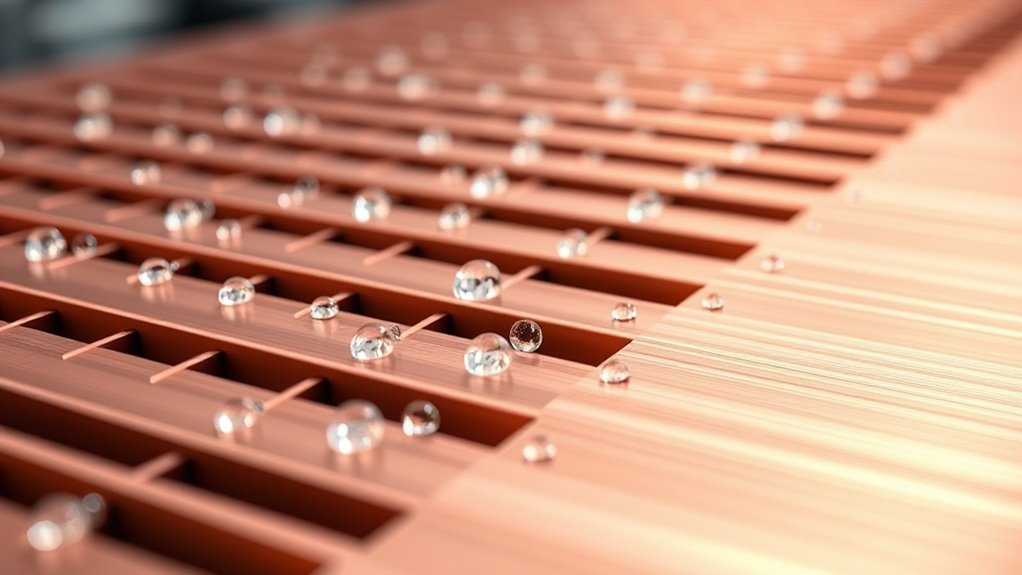

Surface Treatments and Coatings to Reduce Fouling and Enhance Performance

Surface treatments and coatings are essential tools for reducing fouling and boosting the performance of microchannel condensers. Applying nanostructured coatings creates anti fouling surfaces that minimize particle buildup, maintaining ideal heat transfer efficiency. These coatings can repel contaminants and inhibit corrosion, extending the lifespan of your condenser. Anti fouling surfaces help prevent the accumulation of dirt, algae, and mineral deposits that often impair condenser function. By implementing advanced surface treatments, you reduce maintenance needs and operational costs while ensuring consistent performance. Nanostructured coatings are particularly effective because their unique surface features disrupt foulant adhesion. Additionally, understanding state-specific tax laws can help optimize financial strategies related to equipment investments and maintenance costs. Overall, these coatings enhance heat transfer, improve reliability, and maximize condenser longevity, making them crucial in designing high-efficiency microchannel systems.

Advanced Manufacturing Techniques for Precise Channel Fabrication

You can achieve highly precise microchannels using advanced manufacturing techniques like precision microchannel etching. These methods allow for tighter control over channel dimensions, improving overall efficiency. Exploring these fabrication approaches is key to optimizing microchannel condenser performance.

Precision Microchannel Etching

How can manufacturers achieve such precise microchannels in condensers? The answer lies in microchannel etching, a vital technique for precision fabrication. This process uses chemical or plasma-based methods to carve tiny, accurate channels into metal substrates. By controlling etching parameters, you can create uniform, smooth-walled microchannels essential for maximum heat transfer. Precision microchannel etching minimizes defects and ensures consistent dimensions throughout the condenser. This method allows for intricate designs and tight tolerances that other fabrication techniques may struggle to achieve. As a result, you get highly efficient heat exchangers that maximize performance and reliability. Mastering microchannel etching enables you to push the boundaries of microchannel condenser design and manufacturing. Additionally, understanding microchannel applications can help optimize condenser performance and integration.

Advanced Fabrication Methods

What cutting-edge techniques are revolutionizing the fabrication of microchannels in condensers? Advanced manufacturing methods enable precise channel creation, improving microchannel durability and supporting manufacturing scalability. Techniques like laser micro-machining, additive manufacturing, and nanoimprinting allow you to produce complex, high-quality channels efficiently. These methods reduce defects and enhance durability, essential for long-lasting performance. Additionally, they streamline production, making large-scale manufacturing feasible without sacrificing precision and quality.

Computational Modeling and Simulation for Design Optimization

Computational modeling and simulation play a crucial role in optimizing the design of microchannel condensers by enabling you to predict performance accurately before physical prototypes are built. These tools help evaluate fluid flow, heat transfer, and pressure drops efficiently. You can analyze nanofluid applications to enhance heat transfer capabilities and optimize thermal interface materials for improved thermal conductivity. Simulations also assist in identifying ideal geometries and flow arrangements, reducing development costs and time.

- Modeling complex heat transfer phenomena within microchannels

- Evaluating the impact of nanofluids on overall condenser efficiency

- Optimizing thermal interface materials for better thermal performance

Integration of Microchannel Condensers With High-Efficiency Systems

Integrating microchannel condensers with high-efficiency systems offers significant opportunities to enhance overall performance and energy savings. By selecting innovative refrigerant options, you can optimize heat transfer and reduce environmental impact considerations. Microchannel condensers are lightweight and compact, making them ideal for modern high-efficiency systems that demand space-saving solutions. Their design supports the use of low-GWP refrigerants, aligning with environmental regulations and sustainability goals. When integrating these components, it’s vital to evaluate compatibility with existing system components and refrigerant properties to maximize efficiency. This approach not only improves cooling performance but also minimizes energy consumption and greenhouse gas emissions. Properly maintaining eco-friendly practices ensures system longevity and optimal operation. Ultimately, combining microchannel technology with advanced system designs paves the way toward greener, more sustainable cooling solutions.

Managing Pressure Drop and Flow Distribution in Microchannels

Managing pressure drop and flow distribution is vital for ideal microchannel performance. You need to guarantee flow remains uniform to prevent hotspots and reduce unnecessary pressure loss. Focusing on these points helps maintain efficiency and prolong the lifespan of your condenser system. Additionally, implementing proper flow management techniques can further optimize heat transfer efficiency and system reliability.

Balancing Flow Uniformity

Achieving flow uniformity in microchannel condensers requires carefully balancing pressure drops across individual channels to prevent uneven distribution. Proper uniformity control guarantees each microchannel receives consistent flow, optimizing heat transfer efficiency. To achieve this, you should consider:

- Adjusting channel geometries to equalize flow resistance

- Implementing flow restrictors or flow dividers where needed

- Monitoring pressure differences to identify and correct imbalances

- Regularly assessing and adjusting the system to maintain flow consistency over time

Minimizing Pressure Loss

Reducing pressure loss in microchannel condensers is essential for maintaining efficient flow and ideal heat transfer performance. To achieve pressure drop reduction, focus on optimizing channel geometry and surface roughness, which helps minimize flow resistance. Proper flow management ensures uniform distribution across channels, preventing localized pressure drops that can hinder performance. Use strategic inlet and outlet designs to balance flow rates and reduce turbulence, which increases pressure loss. Incorporate flow control devices or manifolds to evenly distribute refrigerant and avoid uneven pressure drops. Maintaining smooth flow paths and avoiding sharp bends or obstructions also contribute to pressure drop reduction. By managing pressure loss effectively, you enhance overall system efficiency, ensuring consistent heat transfer and reliable condenser operation.

Future Trends and Emerging Technologies in Microchannel Condenser Design

Emerging trends in microchannel condenser design focus on enhancing efficiency, sustainability, and adaptability to future cooling demands. Researchers are exploring nanofluid cooling to improve heat transfer rates and reduce temperature gradients. Phase change enhancement technologies are also gaining attention, enabling more effective thermal regulation within confined spaces. Future designs may incorporate smart materials that adapt to load variations, optimizing performance dynamically. Additionally, integrating advanced manufacturing techniques like 3D printing allows for complex geometries that maximize heat exchange. Key innovations include:

Emerging microchannel condenser trends include nanofluids, phase change materials, and smart, 3D-printed designs for enhanced efficiency and sustainability.

- Use of nanofluids for superior heat transfer

- Incorporation of phase change materials for thermal regulation

- Adoption of smart, adaptive condenser systems

- Exploring various cost and budgeting options for manufacturing and deployment to ensure economic feasibility.

These advances aim to create more efficient, durable, and environmentally friendly microchannel condensers suited for evolving cooling challenges.

Frequently Asked Questions

How Do Microchannel Condensers Perform Under Extreme Environmental Conditions?

You might wonder how microchannel condensers perform under extreme conditions. They generally offer excellent thermal efficiency, but exposure to harsh environments can challenge their corrosion resistance. In such settings, selecting materials with high corrosion resistance helps sustain performance. Proper maintenance and protective coatings ensure these condensers stay efficient and durable, even in extreme weather, making them reliable choices for demanding applications.

What Are the Cost Implications of Implementing Advanced Manufacturing Techniques?

When you consider implementing advanced manufacturing techniques, you need to weigh manufacturing costs against potential benefits. These techniques often require significant technology investments upfront, which can increase initial expenses. However, in the long run, you’ll likely see reductions in production costs, enhanced efficiency, and better product quality. Although the initial investment may be high, the improved performance and competitiveness can offset these costs over time, making it a strategic move.

How Does Microchannel Design Affect Refrigerant Compatibility and Environmental Impact?

You should consider how microchannel design influences refrigerant compatibility and environmental impact. Microchannels typically work well with low-GWP refrigerants, reducing harmful emissions. Their compact structure minimizes refrigerant volume, lowering potential leaks and environmental risks. By choosing microchannel condensers, you can enhance sustainability, decrease refrigerant use, and improve overall system efficiency, making your cooling solutions more eco-friendly and aligned with environmental regulations.

What Maintenance Challenges Are Unique to Microchannel Condenser Systems?

Think of your microchannel condenser as a delicate garden needing constant care. You’ll face unique challenges like leak detection, where tiny cracks threaten performance, and fouling prevention, which clogs channels over time. Regular inspections help catch leaks early, while cleaning routines prevent buildup. Staying vigilant guarantees your system runs efficiently, just like tending a garden keeps it thriving. With proper maintenance, your microchannel condenser remains a reliable, eco-friendly powerhouse.

How Can Real-Time Monitoring Improve Microchannel Condenser Efficiency?

You can boost microchannel condenser efficiency by implementing real-time monitoring through sensor integration. These sensors continuously track performance metrics, helping you identify issues early. Data analytics then analyze this data, revealing patterns or inefficiencies. This proactive approach allows you to optimize operation, reduce downtime, and improve heat transfer. By staying ahead of potential problems, you guarantee your system runs smoothly and efficiently, saving energy and maintenance costs over time.

Conclusion

As you refine microchannel condensers, think of each innovation as adding brushstrokes to a masterpiece. Material advances, precise engineering, and smart coatings shape a canvas of efficiency, while simulations and future trends illuminate the horizon like guiding stars. By balancing flow and pressure, you craft a symphony of heat transfer — transforming complex science into a seamless dance of progress. Embrace these symbols, and you’ll open the true potential of thermal excellence.