A reversing valve is a key part of your heat pump that switches refrigerant flow to change between heating and cooling modes. When you set your thermostat to heat, the valve reverses the refrigerant cycle, providing warm air. Switching back to cooling does the opposite. Proper installation, regular maintenance, and prompt repairs guarantee it functions smoothly. If you want to know more about how this valve works and troubleshooting tips, keep exploring.

Key Takeaways

- Reversing valves change refrigerant flow direction to switch between heating and cooling modes seamlessly.

- Proper installation ensures the valve functions correctly and prevents inefficient mode switching.

- Faulty reversing valves can cause failure to switch modes, leading to system inefficiency or breakdown.

- Regular maintenance and inspections help detect issues like refrigerant leaks or valve damage early.

- Professional diagnosis and replacement are recommended for troubleshooting and ensuring optimal system performance.

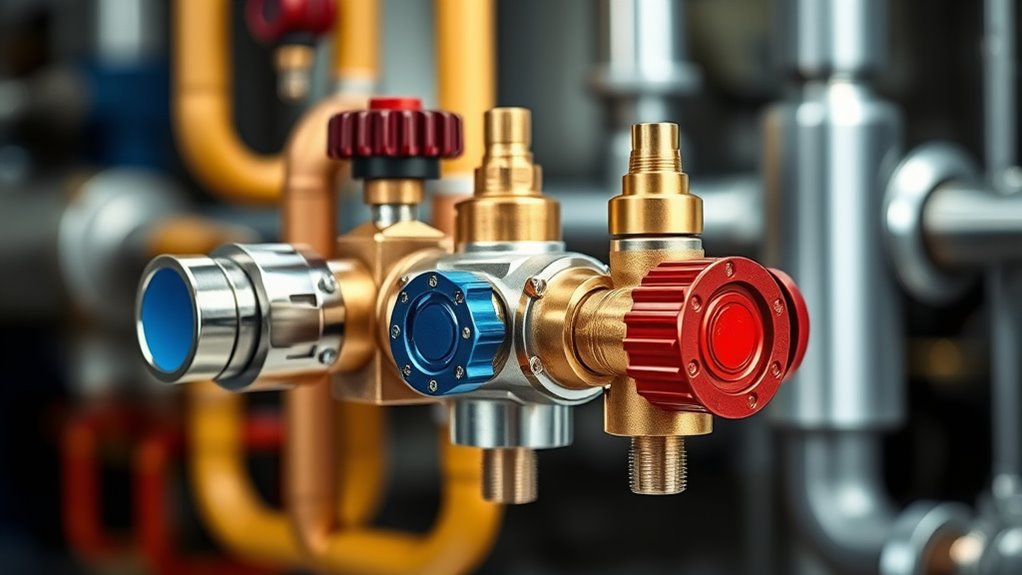

Have you ever wondered how heat pumps switch between heating and cooling modes? The key component responsible for this seamless shift is the reversing valve. This valve changes the direction of refrigerant flow, allowing your heat pump to operate as a heater or air conditioner depending on your needs. Understanding how this component works can help you better appreciate the system’s efficiency and guide you through potential issues. When considering installation, it’s important to keep several factors in mind. Proper placement of the reversing valve is vital; it needs to be accessible for maintenance and positioned to prevent exposure to extreme weather or debris. Ensuring the valve is compatible with your system’s specifications also plays a significant role. Incorrect installation can lead to inefficient switching, increased energy consumption, or even system failure. If you’re installing a new heat pump, consulting with a professional guarantees that all these considerations are addressed correctly, minimizing future problems.

Once installed, the reversing valve works automatically when the thermostat signals a change in mode. When switching from cooling to heating, the valve shifts the refrigerant flow, reversing the cycle. This process is usually smooth, but sometimes you might encounter common troubleshooting issues. For example, if the system fails to switch modes, it could be due to a faulty reversing valve, electrical problems, or control board malfunctions. In such cases, you might notice that your heat pump continues to operate in one mode despite the thermostat settings. Another common issue is refrigerant leaks that can impair the valve’s ability to function properly. Regular maintenance and inspections can help detect these problems early. If the reversing valve is stuck or damaged, replacing it often resolves switching issues, but it’s best to have a professional diagnose and handle repairs to avoid further damage or safety risks.

Frequently Asked Questions

How Long Does It Take to Switch Between Heating and Cooling Modes?

Switching between heating and cooling modes typically takes about 5 to 15 minutes, depending on your system’s switching speed and system compatibility. You might notice a brief period of airflow change or temperature adjustment. If it takes longer, verify your reversing valve functions correctly and your system is compatible with quick switching. Proper maintenance can help optimize the process, making transitions smoother and more efficient.

Can Reversing Valves Fail or Get Stuck Over Time?

Yes, reversing valves can fail or get stuck over time. Their lifespan depends on factors like usage and maintenance. Valve corrosion is a common issue, especially in humid or salty environments, which can cause sticking or failure. Regular inspections and timely maintenance help prevent issues. If your reversing valve gets stuck, it might need repair or replacement to restore proper heating and cooling functions.

Do Reversing Valves Require Regular Maintenance or Inspection?

You should regularly inspect your reversing valve to guarantee proper operation. Reversing valves benefit from lubrication, which prevents wear and sticking, especially given their complex design. Over time, dirt and debris can affect the valve’s performance, so keeping it clean is essential. Proper maintenance helps avoid failure or sticking, making sure your system shifts smoothly between heating and cooling modes. Regular inspections and lubrication keep your reversing valve functioning reliably.

Are There Any Signs Indicating a Reversing Valve Malfunction?

You might notice reversing valve leaks or unusual noise, which are signs of a malfunction. If you hear banging or hissing sounds, it indicates the valve isn’t switching properly. Leaks around the valve also suggest issues. Don’t ignore these signs; they can lead to inefficient heating or cooling. Regular inspection helps catch problems early, ensuring your system runs smoothly and saves you money on repairs later.

Is Specialized Training Needed to Repair or Replace a Reversing Valve?

You do need specialized training to repair or replace a reversing valve. Reversing valve diagnostics can be complex, requiring knowledge of HVAC systems and refrigerant handling. During the replacement procedure, you’ll need to carefully remove and install the valve, guaranteeing proper connections and system operation. Without proper training, you risk damaging components or causing system failure. It’s best to consult a certified technician for reversing valve repairs to ensure safety and proper functioning.

Conclusion

So, next time you flip that reversing valve, remember you’re basically controlling the weather inside your house like a superhero. One second, you’re basking in summer’s glow, and the next, you’re cozy in winter’s embrace—all with a simple switch. It’s like having the power to summon sunshine or snow at will! So, give that valve some love—you’re not just switching heating and cooling; you’re wielding the mighty force of climate control!