To maintain your commercial heat pump HVAC, start with a visual check of external components for damage, corrosion, or debris. Replace or clean filters monthly, inspect and clean coils, and check refrigerant levels for leaks. Test electrical connections and controls, ensure the condensate drain and pan are clear, and lubricate moving parts. Track system performance and document everything. Keep these steps in mind, and you’ll find useful tips on keeping your system running smoothly.

Key Takeaways

- Perform regular external inspections, checking for damage, debris, and ensuring vents and drain lines are clear.

- Check and replace air filters monthly; clean coils and verify refrigerant levels for optimal system performance.

- Test electrical components, including circuit breakers, fuses, and thermostat accuracy, to ensure safe and reliable operation.

- Lubricate moving parts and monitor system performance for unusual noises, cycling, or energy usage fluctuations.

- Maintain detailed records of maintenance activities, schedule routine inspections, and address drainage issues promptly.

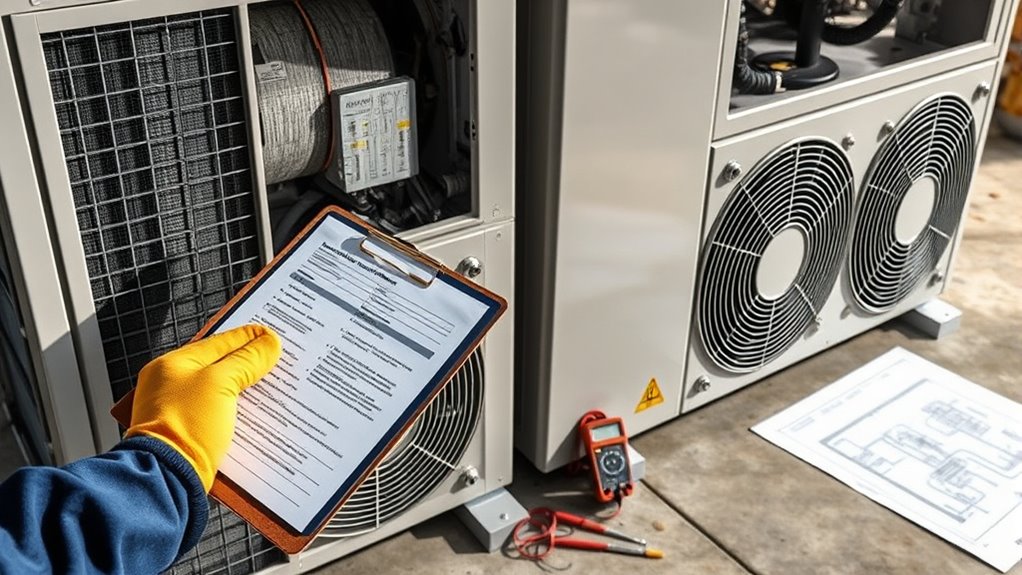

Visual Inspection of External Components

To guarantee your heat pump operates efficiently, start with a thorough visual inspection of its external components. Check for any signs of external damage like dents, cracks, or corrosion that could impair performance. Ensure that all vents and louvers are clear and unobstructed, as debris or debris buildup can restrict airflow. Pay attention to component accessibility; make sure panels and covers are secure and easy to remove for future maintenance. Look for loose or damaged wiring, which could pose safety hazards or disrupt operation. Removing debris such as leaves, dirt, or snow around the unit helps prevent blockages and maintains optimal heat exchange. Regularly inspecting the external components of your heat pump can help identify early signs of wear and tear, allowing for timely repairs. Conducting this visual check regularly allows you to spot issues early, keeping your heat pump running smoothly and efficiently.

Checking and Replacing Air Filters

Regularly checking and replacing your heat pump’s air filters is essential for maintaining ideal airflow and efficiency. Different air filter types, such as pleated, fiberglass, or electrostatic filters, require varying replacement schedules. Generally, you should check filters monthly, especially during peak usage or dusty seasons. Replace filters when they appear dirty, clogged, or after the recommended filter replacement frequency—typically every 1 to 3 months. Using the correct filter type for your system guarantees best performance and indoor air quality. Neglecting this maintenance can lead to reduced airflow, increased energy consumption, and system strain. Keep a routine to inspect filters regularly, and change them promptly to keep your heat pump running smoothly and efficiently. Proper filter maintenance also helps protect your HVAC system components from unnecessary wear and tear.

Inspecting and Cleaning Coils

Dirty coils reduce heat transfer efficiency and can cause your system to work harder, increasing energy costs. Regular cleaning helps maintain ideal performance and extends the lifespan of your equipment. Use appropriate techniques to safely remove dirt and debris without damaging the coils.

Dirty Coils Impact

When coils become coated with dirt and debris, their ability to transfer heat efficiently drops substantially. This buildup insulates the coil material, reducing airflow and causing the system to work harder. Over time, moisture trapped by dirt can lead to coil corrosion, especially if the coil material isn’t corrosion-resistant. Damaged or corroded coils lose their ability to absorb and release heat properly, leading to decreased system performance and higher energy bills. Dirty coils also increase the risk of system breakdowns, as the strain on components intensifies. Regular inspection helps you identify early signs of dirt accumulation and corrosion, so you can address issues before they escalate, ensuring your heat pump runs smoothly and efficiently. Additionally, understanding the importance of Volkswagen Tuning can help you optimize your vehicle’s performance, much like maintaining clean coils ensures HVAC efficiency.

Cleaning Techniques

To effectively maintain your heat pump’s performance, inspecting and cleaning the coils should be a routine part of your service checks. Proper coil cleaning techniques help prevent airflow issues and improve efficiency. Start by turning off the system and removing debris from around the coils. Next, consider these coil cleaning techniques:

- Use a soft brush or vacuum to gently remove dust and dirt.

- Apply a coil cleaner solution, allowing it to sit for several minutes.

- Rinse with low-pressure water, ensuring thorough removal of grime.

- Regularly inspecting and cleaning coils will help maintain HEPA filtration effectiveness and keep your system running smoothly.

While doing this, check your air filter maintenance schedule; a clean filter reduces dirt buildup on coils. Regularly inspecting and cleaning coils will keep your heat pump running smoothly and extend its lifespan.

Examining Refrigerant Levels and Leaks

You need to check refrigerant levels regularly to guarantee ideal system performance. Look for signs of leaks and monitor pressures to catch issues early. Servicing refrigerant lines promptly helps prevent costly repairs and keeps your heat pump running efficiently. Additionally, maintaining proper refrigerant levels is crucial for the overall efficiency of your HVAC system and to ensure it effectively manages indoor climate control.

Detecting Refrigerant Leaks

Detecting refrigerant leaks is a critical step in maintaining the efficiency and longevity of your commercial heat pump HVAC system. To locate leaks, start with refrigerant identification to ensure correct handling. Use leak detection tools like electronic leak detectors or UV dyes to pinpoint the source. Imagine:

- Scanning coils with electronic detectors, sensing faint gas traces.

- Applying UV dye and inspecting with a black light, revealing bright traces at leak points.

- Listening for hissing sounds near fittings or coils that may signify escaping refrigerant.

- Regularly monitoring refrigerant levels and leak detection practices to prevent system failures.

Monitoring Refrigerant Pressures

Monitoring refrigerant pressures provides a clear picture of your heat pump’s operating condition and helps identify potential leaks or system imbalances. Regular refrigerant pressure monitoring guarantees your system runs efficiently, preventing costly breakdowns. Use a calibrated pressure gauge to get accurate readings, as pressure gauge calibration is essential for reliable measurements. Check both the high and low-pressure sides during operation to detect abnormal fluctuations. Consistent pressure readings outside the manufacturer’s specified range could indicate leaks, blockages, or other issues. Maintain a log of pressure readings over time to spot trends and address problems early. Proper refrigerant pressure monitoring not only optimizes system performance but also prolongs equipment lifespan and reduces energy costs. Additionally, understanding refrigerant levels is crucial for maintaining system efficiency and preventing environmental harm.

Servicing Refrigerant Lines

Regularly inspecting refrigerant lines is essential to guarantee proper system performance and prevent leaks. You should check refrigerant levels and look for signs of leaks using leak detection methods. If you suspect a leak, perform refrigerant recovery to safely remove the refrigerant before repairs.

Imagine these key steps:

- Visually inspect lines for oily residue or corrosion indicating leaks.

- Use leak detection tools like electronic detectors or soap solutions to pinpoint leaks precisely.

- Check refrigerant pressure levels to ensure they are within manufacturer specifications, adjusting as needed.

Monitoring refrigerant levels helps prevent system inefficiency, while early leak detection minimizes environmental impact and costly repairs. Proper servicing of refrigerant lines maintains your heat pump’s best performance.

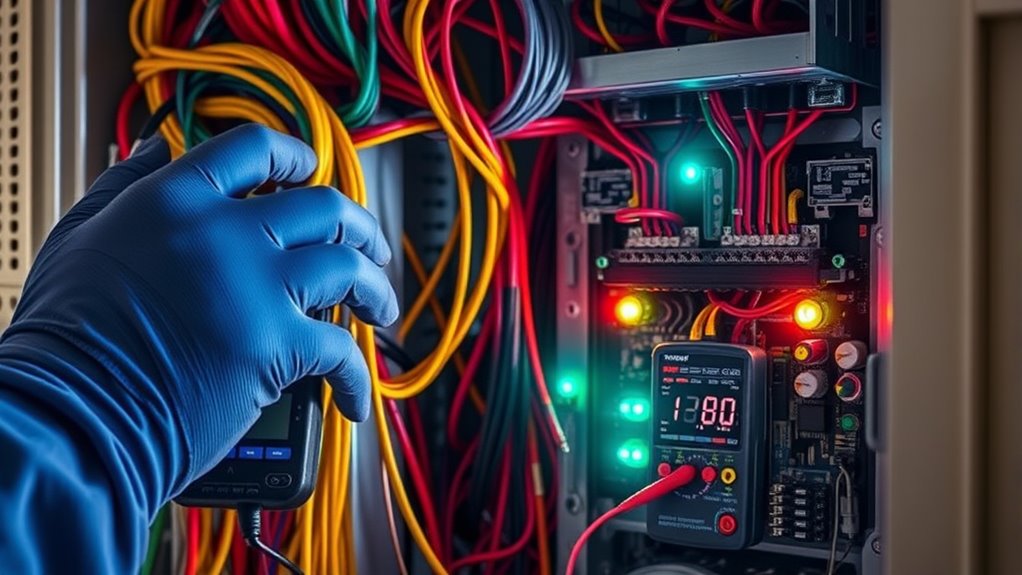

Testing Electrical Connections and Controls

Have you checked the electrical connections and controls recently? Ensuring these are secure and functioning properly is essential for your heat pump’s efficiency. Start with circuit breaker testing—turn off and reset breakers to verify they trip correctly and aren’t showing signs of wear. Next, inspect each fuse for signs of damage or corrosion, replacing any blown or faulty units. Tighten loose wiring connections, making sure they’re secure and free of corrosion or corrosion buildup. Use a multimeter to test voltage and continuity, confirming the controls operate as intended. Proper electrical testing prevents unexpected failures and prolongs equipment life. It’s also important to understand how self watering plant pots work to better maintain related systems. Don’t overlook these steps; regular electrical checks keep your heat pump running smoothly and safely.

Verifying Thermostat Functionality

After confirming that your electrical connections and controls are secure and functioning properly, it’s important to verify your thermostat is accurately reading and controlling your heat pump. Start by checking if your smart thermostat displays the correct current temperature and responds to adjustments. Next, test the remote temperature feature by changing settings from a different location or device to ensure it updates promptly. Finally, manually set your thermostat to different modes—heating, cooling, and off—and observe if your heat pump responds correctly. Picture yourself adjusting the remote temperature and hearing the system activate smoothly. Ensuring these functions work properly helps maintain efficient operation and comfort. Regularly verifying thermostat functionality keeps your HVAC system operating at peak performance. Additionally, being aware of the regional resources available can assist in troubleshooting if issues persist.

Inspecting the Condensate Drain and Pan

Inspecting the condensate drain and pan is essential to prevent water buildup and potential damage to your heat pump. Begin with a drain pan inspection to ensure it’s free of debris, mold, or algae that could block proper drainage. Check for cracks or corrosion that might cause leaks. Next, inspect the condensate drain line for clogs or obstructions. Regular condensate drain cleaning helps maintain unobstructed flow, reducing the risk of overflow or water damage. Clear any dirt, algae, or algae buildup from the drain line and pan. If you notice standing water or slow drainage, address these issues promptly to prevent mold growth or water damage. Proper inspection and cleaning keep your heat pump operating efficiently and protect your investment from costly repairs. Additionally, understanding the importance of security measures can help prevent unauthorized access to your HVAC system’s control components.

Lubricating Moving Parts

Proper lubrication of moving parts in your heat pump helps guarantee smooth operation and reduces wear over time. Regularly lubricate components like bearings and motors to prevent friction and overheating. Focus on these key areas:

- Apply bearing lubrication to ensure the shaft rotates smoothly without noise or resistance.

- Use appropriate lubricant during motor maintenance to keep the motor’s moving parts functioning efficiently.

- Check for signs of wear or dryness and reapply lubricant as needed to avoid costly repairs.

Assessing System Performance and Efficiency

To guarantee your heat pump operates at peak efficiency, you need to regularly assess its performance. Start by monitoring system energy consumption to identify any unusual increases that may indicate issues. Check the thermostat for accuracy and ensure the system responds correctly to temperature adjustments. Evaluate airflow and refrigerant levels, as poor airflow can reduce efficiency. Keep an eye on outdoor air quality, since debris or pollutants can impact system operation and cause strain. Listen for unusual noises and observe if the system cycles on and off frequently. These signs can signal underlying problems affecting performance. Regular assessments help you catch inefficiencies early, saving energy and prolonging equipment lifespan. Staying proactive ensures your heat pump runs smoothly and efficiently year-round.

Documenting Maintenance Activities and Scheduling Next Service

Keeping detailed records of all maintenance activities is essential for maintaining your heat pump’s efficiency and reliability. Accurate record keeping helps you track past repairs, identify recurring issues, and guarantee nothing gets overlooked. When you document each service, you create a clear history that simplifies scheduling reminders for future maintenance. To stay organized, consider:

- Updating a maintenance log after every service, noting tasks completed and parts replaced.

- Setting scheduled reminders in your calendar for upcoming inspections or filter changes.

- Reviewing records regularly to identify patterns and plan proactive maintenance.

Frequently Asked Questions

How Often Should Maintenance Checks Be Scheduled for Commercial Heat Pumps?

You should schedule routine inspections and seasonal servicing for your commercial heat pump HVAC systems to keep them running smoothly. Typically, it’s best to perform these checks at least twice a year—before the heating and cooling seasons. Regular maintenance helps catch issues early, improves efficiency, and extends the lifespan of your equipment. Stay proactive with these scheduled checks to ensure peak performance and prevent costly repairs down the line.

What Are Common Signs Indicating the Need for Professional Repairs?

Imagine your heat pump suddenly struggles to heat or cool effectively—that’s a clear warning indicator. You should watch for signs like unusual noises, increased energy bills, or refrigerant leaks, which serve as repair triggers. These warning indicators suggest professional repairs are needed. Ignoring them can lead to bigger issues or system failure, so act promptly when you notice these signs to keep your system running smoothly.

Are There Specific Safety Precautions to Follow During Maintenance?

When performing maintenance, you need to prioritize safety precautions. Always wear appropriate safety gear, such as gloves and eye protection, to prevent injuries. Be aware of potential hazards like electrical components or refrigerant leaks, which can pose serious risks. Confirm the power is disconnected before working on the system, and follow safety guidelines carefully. By maintaining hazard awareness and using proper safety gear, you reduce the risk of accidents and keep your work safe.

How Can I Improve Energy Efficiency Beyond Standard Checklists?

To improve energy efficiency beyond standard checklists, you can implement energy-saving tips like optimizing system settings and sealing ductwork. Consider retrofit upgrades such as high-efficiency motors or advanced controls that enhance performance. Regularly monitor system performance and adjust as needed, ensuring your heat pump operates at peak efficiency. These proactive steps help reduce energy consumption, lower costs, and extend the lifespan of your HVAC system.

What Warranty Coverage Applies After Performing Maintenance?

After performing maintenance, you should review your warranty coverage carefully. Warranty exclusions often specify what services or repairs aren’t covered, so understanding these is vital. Keep thorough maintenance documentation to support any warranty claims, demonstrating you followed recommended procedures. If issues arise, contact your provider promptly, referencing your documentation. Doing so helps make sure you maximize your warranty benefits and avoid unexpected costs.

Conclusion

Think of your heat pump as a trusted vessel sailing smoothly through seasons. Regular maintenance is your compass, guiding it past storms of dirt and wear. With each checklist item, you’re steering toward efficiency and longevity, keeping the journey quiet and steady. Stay vigilant and attentive, and your system will continue to navigate the climate’s currents confidently, ensuring comfort and reliability on every voyage. Your proactive care keeps the voyage smooth and secure.