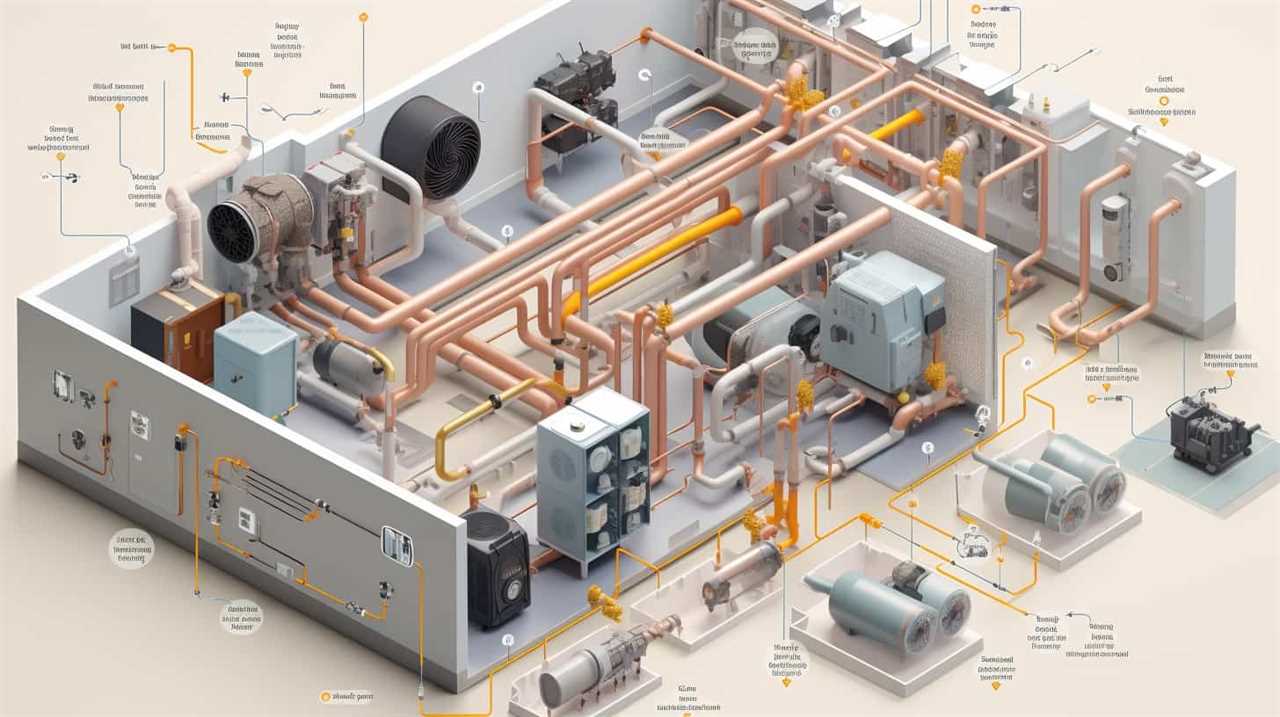

Curious about the inner workings of heat pump refrigeration systems? Join us as we delve into the essential components that make these systems function seamlessly.

From the importance of the compressor to understanding the evaporator, exploring the condenser, and the role of the expansion valve, we will cover it all.

We’ll also discuss heat transfer, different refrigerant types, energy efficiency considerations, troubleshooting common issues, and the importance of maintenance and care.

Let’s dive in and uncover the secrets behind heat pump refrigeration.

Key Takeaways

- The compressor is an important component in heat pump refrigeration.

- Understanding the evaporator is crucial in the refrigeration cycle.

- The condenser plays a significant role in heat transfer in the refrigeration process.

- The expansion valve has a specific function in regulating pressure and temperature in the system.

The Importance of the Compressor

As we delve into the key elements of heat pump refrigeration, it’s important to understand the significance of the compressor. The compressor plays a vital role in the refrigeration process, as it’s responsible for increasing the pressure and temperature of the refrigerant, enabling it to effectively absorb and release heat.

One key aspect to consider when it comes to the compressor is its efficiency. A highly efficient compressor can significantly reduce energy consumption, leading to cost savings and environmental benefits.

Regular compressor maintenance is essential to ensure optimal performance and longevity. This includes tasks such as cleaning the compressor coils, checking refrigerant levels, and inspecting for any leaks or damage.

Understanding the Evaporator

Let’s dive into the evaporator, a crucial component in heat pump refrigeration systems.

The evaporator is responsible for absorbing heat from the surrounding environment, allowing the refrigerant to evaporate and turn into a gas. This process occurs through a series of coils, where the refrigerant is circulated.

The evaporator plays a vital role in maintaining the efficiency of the heat pump system, as it determines how well the heat is absorbed. To ensure optimal performance, it’s important to regularly check and clean the evaporator coils, as frost buildup can hinder its efficiency.

Proper maintenance and cleaning of the evaporator coils will help prevent frost buildup and ensure the efficient operation of the heat pump system.

Now, let’s move on to explore the condenser and its role in heat pump refrigeration systems.

Exploring the Condenser

Now, we’ll delve into the condenser, a crucial component in heat pump refrigeration systems. The condenser plays a vital role in the refrigeration cycle by transferring heat from the refrigerant to the surrounding environment. To ensure optimal performance and efficiency, condenser maintenance is essential.

Here are four key aspects to consider when it comes to condenser maintenance:

Condenser Coil Cleaning: Regular cleaning of the condenser coils is necessary to remove any dirt, debris, or buildup that can hinder heat transfer. This can be done by using a soft brush or vacuum to gently remove the accumulated dust.

Inspection of Fins and Tubes: It’s important to inspect the condenser fins and tubes for any damage or corrosion. Damaged fins should be straightened or replaced, and corroded tubes should be repaired or replaced to prevent further deterioration.

Checking for Airflow Obstructions: Clearing any obstructions around the condenser, such as vegetation or debris, is crucial to maintain proper airflow. This will prevent the condenser from overheating and ensure efficient heat transfer.

Monitoring Refrigerant Levels: Regularly monitoring the refrigerant levels in the condenser is necessary to ensure optimal performance. Any leaks or low refrigerant levels should be promptly addressed to prevent system inefficiencies.

By implementing these condenser maintenance practices, you can ensure the longevity and efficiency of your heat pump refrigeration system.

Now, let’s explore the role of the expansion valve in the refrigeration cycle.

The Role of the Expansion Valve

To understand the refrigeration cycle fully, we must explore the role of the expansion valve. The expansion valve is a crucial component in heat pump refrigeration systems, responsible for regulating the flow of refrigerant between the high-pressure side and the low-pressure side of the system. Its primary function is to control the amount of refrigerant entering the evaporator coil, where it absorbs heat from the surrounding air or water.

The expansion valve works by creating a pressure drop in the refrigerant, causing it to expand and cool down as it enters the evaporator. This drop in pressure enables the refrigerant to absorb heat from the desired source, thus cooling down the space or fluid being served.

However, like any other component, the expansion valve can experience issues that require troubleshooting. Common problems include blockages, leaks, or improper adjustment. It is crucial to address these issues promptly to ensure optimal performance and efficiency of the heat pump refrigeration system.

To help you understand the importance of the expansion valve and its troubleshooting, here is a table summarizing its function and common troubleshooting techniques:

| Expansion Valve Function | Expansion Valve Troubleshooting |

|---|---|

| Regulates refrigerant flow | Check for blockages or leaks |

| Controls pressure drop | Adjust valve settings if needed |

| Enables heat absorption | Monitor system performance |

Heat Transfer in the Refrigeration Cycle

Heat transfer is a crucial aspect of the refrigeration cycle, as it enables the movement of thermal energy from one location to another. In the context of a heat pump, heat transfer occurs in four key stages.

Evaporation: Heat is absorbed from the surroundings as the refrigerant evaporates, converting from a liquid to a gas.

Compression: The gaseous refrigerant is compressed, increasing its temperature and pressure.

Condensation: Heat is released to the surroundings as the refrigerant condenses back into a liquid, transferring thermal energy.

Expansion: The refrigerant expands, causing its temperature and pressure to decrease, preparing it for the next cycle.

Advancements in heat pump technology have focused on improving heat transfer efficiency, resulting in more energy-efficient systems that can provide greater heating or cooling capabilities while reducing energy consumption.

Pressure and Temperature Regulation

We regulate the pressure and temperature in the refrigeration system to ensure optimal performance and efficiency.

Pressure control is crucial in maintaining the appropriate conditions for the refrigerant to undergo phase changes and transfer heat effectively. By adjusting the pressure, we can control the boiling and condensing temperatures, which, in turn, affect the heat transfer rates. This allows us to match the system’s capacity with the desired cooling or heating load.

To achieve this, we utilize pressure regulators and valves that respond to changes in pressure within the system.

Temperature regulation is also essential for maintaining the desired cooling or heating effect. Through the use of thermostats and sensors, we can monitor and adjust the temperature to ensure comfort and energy efficiency.

Refrigerant Types and Properties

When considering refrigerant types and properties, it’s important to evaluate their environmental impact. Certain refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been found to deplete the ozone layer and contribute to global warming. In contrast, newer refrigerants like hydrofluorocarbons (HFCs) and natural refrigerants have lower environmental impact.

Additionally, energy efficiency is a crucial factor in choosing a refrigerant, as it directly affects the performance and operating costs of heat pump systems.

Environmental Impact of Refrigerants

There are several different types of refrigerants, each with their own unique properties and environmental impacts. When considering the environmental impact of refrigerants, it’s important to take into account factors such as their global warming potential (GWP) and ozone depletion potential (ODP).

Here are four key points to consider regarding the environmental impact of refrigerants:

GWP: This measures the potential of a refrigerant to contribute to global warming over a given time period. Refrigerants with higher GWP values have a greater impact on climate change.

ODP: This measures the potential of a refrigerant to deplete the ozone layer. Refrigerants with higher ODP values have a greater impact on ozone depletion.

Recovery and disposal: Proper recovery and disposal of refrigerants are essential to prevent their release into the environment and minimize their impact on climate change and ozone depletion.

Alternative refrigerants: The development and use of alternative refrigerants with lower GWP and ODP values is crucial in reducing the environmental impact of refrigerants.

Energy Efficiency Comparison

To evaluate the energy efficiency of different refrigerant types and properties, we can compare their performance using a compound preposition and coordinating conjunction. One of the key factors in determining the energy efficiency of a heat pump refrigeration system is the efficiency of the compressor. The compressor is responsible for compressing the refrigerant, which increases its temperature and pressure, allowing it to absorb heat from the surroundings. A more efficient compressor will require less energy to accomplish this task, resulting in higher energy efficiency for the system. Another important aspect to consider is refrigerant leakage. Refrigerant leakage can lead to a decrease in the system’s overall efficiency as well as environmental concerns. By selecting a refrigerant with low leakage rates, we can further improve the energy efficiency and reduce the impact on the environment.

| Refrigerant Type | Compressor Efficiency | Refrigerant Leakage |

|---|---|---|

| R-22 | Moderate | High |

| R-410A | High | Low |

| R-32 | High | Low |

| R-1234yf | High | Low |

In the table above, we compare the compressor efficiency and refrigerant leakage of different refrigerant types commonly used in heat pump refrigeration systems. It is evident that R-410A, R-32, and R-1234yf have higher compressor efficiency and lower refrigerant leakage compared to R-22. Choosing a refrigerant with high compressor efficiency and low leakage rates can greatly enhance the energy efficiency of a heat pump refrigeration system, resulting in lower energy consumption and reduced environmental impact.

Energy Efficiency Considerations

We should look into ways to optimize energy efficiency in heat pump refrigeration systems. Improving energy efficiency not only reduces operating costs but also helps to minimize the impact on the environment.

Here are four key considerations for enhancing energy efficiency in heat pump refrigeration systems:

Compressor Efficiency: The compressor is a critical component of the heat pump system, and improving its efficiency can lead to significant energy savings. Consider using variable speed compressors or optimizing the compressor control algorithms to match the load requirements more accurately.

System Design: Proper system design plays a crucial role in energy efficiency. Ensure that the system is sized appropriately for the cooling load, and the refrigerant circuit is optimized to minimize pressure drops and maximize heat transfer efficiency.

Insulation: Enhancing insulation levels in the refrigeration system can help reduce heat gain or loss, improving overall energy efficiency. Insulate pipes, ducts, and equipment to minimize energy losses and maintain optimal temperature levels.

Maintenance and Monitoring: Regular maintenance and monitoring are essential to ensure the ongoing energy efficiency of the heat pump refrigeration system. Inspect and clean coils, filters, and fans regularly, and monitor system performance to identify any inefficiencies or issues promptly.

Troubleshooting Common Issues

When it comes to troubleshooting common issues with heat pump refrigeration systems, there are a few key points to consider.

One common issue is a noisy heat pump, which can be caused by a variety of factors such as loose components or a malfunctioning fan motor.

Another common issue is inconsistent temperature output, which could be due to a refrigerant leak or a faulty thermostat.

Noisy Heat Pump

Experiencing a noisy heat pump can be frustrating, but troubleshooting common issues can help identify and resolve the problem. Here are four potential causes of a noisy heat pump and steps you can take to address them:

Loose parts: Check for loose screws, bolts, or fan blades. Tighten any loose components to reduce vibrations and noise.

Faulty fan motor: If the noise is coming from the outdoor unit, the fan motor may be faulty. Inspect the motor for any signs of damage or wear and replace it if necessary.

Refrigerant issues: Low refrigerant levels can cause the heat pump to work harder and produce excessive noise. Schedule a professional inspection to check for leaks and replenish the refrigerant as needed.

Airflow restrictions: Blocked or dirty air filters, vents, or ducts can disrupt airflow and lead to noisy operation. Clean or replace filters regularly and ensure that air vents and ducts are clear of obstructions.

Regular heat pump maintenance and implementing noise reduction measures can help keep your heat pump running smoothly and quietly.

Inconsistent Temperature Output

To troubleshoot common issues with inconsistent temperature output, we can identify three potential causes and take appropriate steps to resolve them. The table below outlines these common causes and provides troubleshooting tips:

| Common Causes | Troubleshooting Tips |

|---|---|

| Malfunctioning thermostat | Check thermostat settings and recalibrate if necessary. |

| Refrigerant leak | Inspect for visible leaks and repair or replace as needed. |

| Clogged air filter | Clean or replace air filter to improve airflow. |

Maintenance and Care for Heat Pump Refrigeration Systems

As we delve into the key elements of heat pump refrigeration, it’s important to understand the maintenance and care required for these systems. Proper maintenance and care not only ensure the longevity of the equipment but also optimize its performance.

Here are four essential maintenance tasks for heat pump refrigeration systems:

Regular Filter Replacement: The air filters in heat pump refrigeration systems play a critical role in maintaining indoor air quality and system efficiency. Regularly replacing the filters, typically every one to three months, prevents dust and debris buildup, ensuring optimal airflow and reducing strain on the system.

Scheduled Maintenance: Regular maintenance by a qualified technician is crucial for heat pump refrigeration systems. This includes inspecting and cleaning the system’s coils, checking refrigerant levels, lubricating moving parts, and testing electrical connections. These tasks help identify and address potential issues before they become major problems.

Cleaning the Outdoor Unit: The outdoor unit of a heat pump refrigeration system is exposed to various elements, including dirt, leaves, and debris. Regularly cleaning the unit’s exterior and removing any obstructions ensures proper airflow and prevents damage to the system.

Monitoring Performance: Keep an eye on the system’s performance to detect any changes or issues promptly. This includes monitoring temperature output, airflow, and any unusual noises or smells. If any concerns arise, contact a professional technician for further evaluation and necessary repairs.

Frequently Asked Questions

What Are the Main Components of a Heat Pump Refrigeration System?

The main components of a heat pump refrigeration system include the evaporator, compressor, condenser, and expansion valve. These components work together to transfer heat from one location to another, making heat pump technology highly efficient.

How Does a Heat Pump Refrigeration System Work?

A heat pump refrigeration system operates by transferring heat from one location to another using a compressor and refrigerant. It operates on the principle of heat pump efficiency, maximizing the heat transfer process to provide effective cooling or heating.

What Are the Advantages of Using a Heat Pump Refrigeration System?

The advantages of using a heat pump refrigeration system include energy efficiency and environmental sustainability. It is a technical, precise, and detailed solution that serves others by reducing energy consumption and minimizing environmental impact.

What Are the Common Issues That Can Occur in a Heat Pump Refrigeration System?

When it comes to heat pump refrigeration systems, we’ve encountered various issues. But with our troubleshooting tips and knowledge of common maintenance issues, we’re able to keep them running smoothly and efficiently.

How Often Should a Heat Pump Refrigeration System Be Maintained and Cared For?

Maintaining and caring for a heat pump refrigeration system is crucial. The frequency at which it should be done depends on factors such as usage and environment. Regular maintenance is of utmost importance to ensure optimal performance and longevity of the system.

What Are the Main Components of a Heat Pump Refrigeration System?

The main components of a heat pump refrigeration system, also known as heat pump refrigeration components, include a compressor, condenser, expansion valve, and evaporator. The compressor circulates the refrigerant, while the condenser releases heat. The expansion valve controls the flow of refrigerant, and the evaporator absorbs heat from the surroundings. Together, these components facilitate the process of heat transfer, allowing the heat pump to efficiently heat or cool spaces.

Conclusion

In conclusion, delving into the key elements of heat pump refrigeration allows us to appreciate the intricate workings of these systems. Understanding the importance of the compressor, evaporator, condenser, and expansion valve, along with heat transfer and refrigerant types, is essential for maximizing energy efficiency.

By troubleshooting common issues and providing proper maintenance and care, we can ensure the longevity and optimal performance of heat pump refrigeration systems. Just as a skilled conductor orchestrates a symphony, mastering these elements orchestrates the cooling process, creating a harmonious and efficient environment.