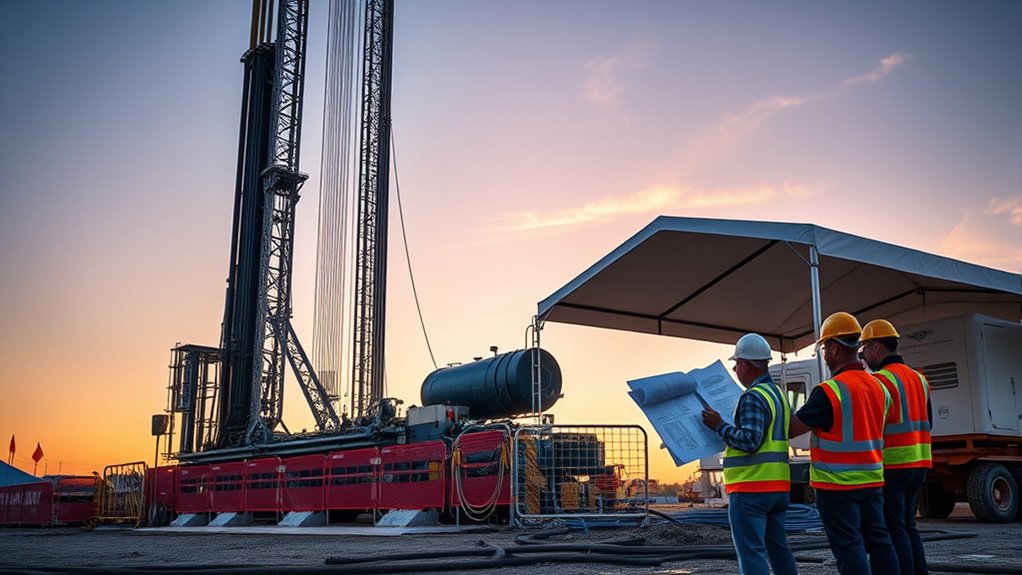

To drill vertical borehole systems effectively, you need to start with thorough site assessments and geological surveys to evaluate soil stability, groundwater flow, and potential hazards. Choose appropriate drilling equipment and techniques, such as suitable drilling fluids and casing, to guarantee stability and safety. Obtain all necessary permits and comply with regulations, while implementing strict safety protocols and risk management measures. Proper design, depth planning, and environmental considerations are key. Continuing your exploration will uncover more detailed requirements for successful borehole projects.

Key Takeaways

- Conduct comprehensive site assessments and geological surveys to determine soil stability, subsurface hazards, and aquifer locations.

- Select appropriate drilling equipment, techniques, and borehole materials based on geological and hydrogeological data.

- Determine optimal borehole depth considering water demand, geological layering, and aquifer thickness to prevent over-drilling.

- Implement proper casing, cementing, and flow testing procedures to ensure borehole stability, longevity, and performance.

- Obtain necessary permits, conduct environmental impact assessments, and engage communities to ensure regulatory compliance and sustainability.

Site Assessment and Geological Surveys

Have you ever wondered why thorough site assessment and geological surveys are essential before drilling a vertical borehole system? These steps help you determine soil stability, ensuring the ground can support the borehole and prevent future subsidence or collapse. Conducting groundwater analysis is equally important, as it reveals water table levels and aquifer locations, guiding your drilling plan and preventing unexpected water encounters. Additionally, understanding subsurface conditions can help identify potential hazards such as fault lines or unstable rock formations that might affect drilling safety. Without proper assessment, there’s a risk of choosing an unsuitable site, which can lead to costly delays or structural issues. By evaluating soil conditions and groundwater presence beforehand, you optimize drilling efficiency and safety. Comprehensive site evaluation can also detect contamination risks that could impact the integrity of the borehole, ensuring long-term stability. Incorporating geotechnical data into your planning process provides a comprehensive understanding of the subsurface environment, further reducing unforeseen complications. Skipping this step might seem tempting, but it could compromise the integrity of your entire project and increase long-term maintenance costs. A detailed geological survey provides vital data to inform the design and placement of the borehole, reducing unforeseen complications. Vetted – Mother Baby Kids thorough site assessment sets the foundation for successful borehole installation.

Drilling Equipment and Technique Selection

Choosing the right drilling equipment and techniques is vital to the success of your vertical borehole system. Selecting appropriate drill pipe and managing drilling fluid are essential for maintaining stability and preventing blowouts. Efficient equipment minimizes downtime and enhances safety, ensuring smooth operation throughout the process. Consider equipment that matches your geological conditions and borehole depth to maximize performance. Proper technique selection, including the type of drilling fluid used, can improve cuttings removal and reduce wear on drill pipes. Additionally, understanding the importance of specialized drilling tools can further optimize your drilling operations. Incorporating well-being tips, such as proper equipment maintenance and safety protocols, can also contribute to successful drilling projects. Using suitable filtration systems can enhance debris management and protect equipment from damage. Paying attention to casing and cementing practices can also improve borehole stability and longevity. Moreover, staying informed about industry standards can help ensure compliance and operational efficiency.

Permitting and Regulatory Compliance

Before you start drilling, you need to understand the permitting process and guarantee you meet all regulatory standards. This involves obtaining the necessary approvals and adhering to local, state, and federal guidelines. Staying compliant helps avoid delays and potential legal issues down the road. Additionally, understanding self watering plant pots can inform environmentally responsible practices during drilling projects. Incorporating space and organization strategies can also help streamline your project setup and ensure efficient use of resources. Being aware of nutritional considerations can further promote sustainable and health-conscious project practices. Implementing efficient general ledger coding can also assist in tracking project expenses and maintaining financial transparency throughout the process. Recognizing signs of bad lemon juice can help prevent contamination risks during material handling and storage.

Permitting Process Overview

What steps are involved in obtaining the necessary permits for vertical borehole systems? You’ll need to navigate a process that assesses environmental impact and emphasizes community engagement. First, submit an application detailing your project scope, location, and potential impacts. Then, authorities review your submission, considering factors like groundwater protection and local ecosystem effects. Additionally, conducting environmental impact assessments to ensure minimal ecological disruption is essential before approval. A thorough understanding of regulatory compliance helps streamline the approval process and avoid delays. Lastly, you may need to attend public hearings or consultations to address community concerns. Key points include:

- Conducting environmental impact assessments to ensure minimal ecological disruption

- Engaging local communities early to gather feedback and foster transparency

- Complying with regional and national regulations for water and land use

- Implementing risk management strategies to handle potential project challenges

Following these steps guarantees your project aligns with regulatory standards and secures the necessary approvals to proceed smoothly.

Regulatory Standards Compliance

Ensuring your vertical borehole system complies with regulatory standards is essential for a smooth project approval process. You need to understand how environmental impact assessments influence permitting and guarantee your system meets local, state, and federal regulations. Proper compliance minimizes the risk of delays or legal issues, saving you time and money. Conducting a thorough cost analysis helps you evaluate expenses related to permits, environmental mitigation, and potential modifications. Staying current on regulatory standards also helps you avoid costly fines or project shutdowns. By proactively addressing environmental concerns and adhering to all legal requirements, you ensure your project progresses efficiently. Ultimately, regulatory standards compliance safeguards your investment and promotes sustainable, responsible drilling practices.

Borehole Design and Depth Planning

Designing a borehole begins with carefully determining its depth to meet specific project goals and geological conditions. Conducting a thorough hydrogeological analysis helps identify groundwater flow, quality, and potential hazards that influence depth decisions. Proper borehole material selection ensures durability and compatibility with site conditions, reducing long-term maintenance issues. You should consider factors like aquifer thickness, geological layering, and water demand when planning depth. Consulting geological surveys and previous borehole data can refine your estimates. Depth planning also involves balancing economic costs with technical requirements, avoiding excessive drilling while ensuring sufficient access to resources. Clearly defining these parameters upfront guarantees ideal borehole performance and longevity. To enhance your design, focus on these core considerations:

- Hydrogeological analysis

- Borehole material selection

- Depth optimization strategies

Safety Protocols and Risk Management

After establishing the borehole’s depth and materials, prioritizing safety protocols and risk management becomes essential to protect personnel and ensure successful operations. You must implement strict well control procedures to prevent blowouts or fluid releases that could endanger workers and cause environmental contamination. Regularly monitor drilling parameters, pressure levels, and fluid returns to detect early signs of well instability. Proper safety gear, training, and emergency response plans are critical for minimizing risks. Managing environmental impact involves controlling waste disposal, preventing spills, and reducing emissions. Staying vigilant and adhering to safety standards helps you avoid accidents, protect the environment, and maintain compliance with regulations. Clear communication and thorough risk assessments are crucial for a safe, efficient drilling process.

Post-Drilling Installation and Testing

Once the drilling process concludes, you’ll need to focus on the installation and testing of your borehole system. Proper post-drilling steps guarantee reliable operation and long-term efficiency. First, verify the integrity of the borehole, checking for stability and proper lining. Next, select the appropriate drilling fluid, considering factors like porosity and mineral content, to optimize borehole stability and facilitate borehole maintenance. Conduct flow tests to confirm the yield meets your project’s requirements, adjusting as needed. Finally, document all results and prepare for ongoing maintenance. These steps help maintain borehole performance, prevent future issues, and ensure safety. Be thorough in your testing, and keep detailed records to streamline future maintenance activities and troubleshooting.

Frequently Asked Questions

How Do Temperature Variations Affect Borehole Drilling Decisions?

Temperature variations influence your borehole drilling decisions profoundly. As you encounter thermal expansion, the surrounding rock and casing may expand or contract, affecting stability. Temperature gradients can create stress zones, leading to potential fractures or shifts. You need to contemplate these factors to choose appropriate materials and techniques, ensuring the borehole remains stable. Monitoring temperature changes during drilling helps you adapt your approach, preventing issues caused by thermal effects.

What Are the Environmental Impacts of Deep Borehole Drilling?

You should know that deep borehole drilling can disturb habitats and pose significant environmental risks—studies show that over 70% of projects impact local ecosystems. These disturbances can lead to habitat loss, groundwater contamination, and soil erosion. By understanding these effects, you can better assess how drilling activities might harm wildlife and ecosystems, encouraging safer practices that minimize environmental impacts and promote sustainable resource extraction.

How Is Groundwater Quality Monitored During and After Drilling?

You should regularly check water quality during and after drilling using established monitoring protocols. These protocols involve collecting water samples at different depths and times, then analyzing them for contaminants, pH, and other parameters. By doing so, you guarantee the borehole remains safe and sustainable. Consistent monitoring helps detect any changes early, allowing for timely intervention to protect groundwater resources and maintain water quality standards.

What Advanced Technologies Improve Drilling Accuracy and Efficiency?

You can improve drilling accuracy and efficiency by utilizing advanced technologies like rotary steerable systems, which allow precise directional control without stopping drilling. Additionally, mud logging provides real-time data on cuttings and formation pressures, helping you make informed decisions quickly. These tools streamline the process, reduce downtime, and enhance overall accuracy, ensuring your vertical borehole drilling is more efficient and effective.

How Are Borehole Abandonment and Decommissioning Handled?

Borehole abandonment and decommissioning demand diligent, detailed procedures. You’ll plug and patch the borehole, ensuring all hazardous materials are properly handled. Decommissioning procedures involve removing equipment, sealing wellbores with cement, and restoring the site. This careful process prevents environmental contamination and future hazards. By following strict abandonment and decommissioning protocols, you guarantee safety, sustainability, and compliance, closing the chapter on the borehole’s lifecycle responsibly and reliably.

Conclusion

As you complete the drilling process, picture the vertical borehole as a lifeline slicing through earth’s layers, connecting your project to unseen underground worlds. Every step, from site assessment to testing, shapes this conduit’s strength and reliability. With careful planning and adherence to safety, you create a pathway that endures, much like a steady heartbeat beneath the surface—silent yet essential, supporting your vision beneath the world’s surface, ready to serve for years to come.