Refrigerant glide occurs when blends experience phase separation during boiling or condensation, causing temperature variations that impact heat transfer efficiency. This uneven temperature distribution can lead to thermal stratification, localized hot or cold spots, and reduced system performance. Managing glide is essential for optimizing heat exchange and system stability. If you want to understand how to control refrigerant glide and improve your system’s efficiency, you’ll find useful insights ahead.

Key Takeaways

- Refrigerant glide causes temperature variations during phase change, affecting heat transfer efficiency.

- High glide can create uneven temperature zones, leading to thermal stratification and reduced heat exchanger performance.

- Managing refrigerant glide improves system stability, energy efficiency, and prevents localized hot or cold spots.

- Proper measurement and selection of refrigerants help minimize glide-related issues in heat exchange processes.

- Designing systems with glide considerations ensures optimized heat transfer and extends equipment lifespan.

Understanding Refrigerant Composition and Phase Change

Understanding refrigerant composition and phase change is essential for grasping how refrigeration systems work efficiently. When refrigerants are blended, they can experience phase separation, which occurs when different components separate during boiling or condensation. This separation impacts heat transfer and system performance, causing uneven temperatures and pressure fluctuations. Recognizing how refrigerant blending influences phase behavior helps you appreciate why some refrigerants are designed as blends rather than pure substances. These blends often exhibit glide, where the saturation temperature varies across the mixture during phase change. By understanding these concepts, you can better diagnose issues related to refrigerant mixture stability and optimize system operation to prevent inefficiencies caused by improper phase separation or incompatible blends. Moreover, developing a keen awareness of full attention during system maintenance can significantly improve troubleshooting accuracy and ensure optimal performance.

The Concept of Saturation Temperature and Pressure

Saturation temperature and pressure are fundamental concepts that describe the state at which a refrigerant changes phase between liquid and vapor. At this point, the refrigerant reaches phase equilibrium, where both phases coexist. The pressure temperature correlation links these two properties: as pressure increases, the saturation temperature also rises. This relationship helps you determine the precise conditions for phase change, essential for designing and operating refrigeration systems. The saturation temperature is the temperature at which the refrigerant begins to boil or condense at a given pressure, providing a clear reference for system performance. Understanding this correlation enables you to predict how changes in pressure affect temperature, ensuring efficient heat exchange and proper system regulation. Additionally, accurate control of saturation conditions is vital for optimizing system efficiency and preventing issues such as overheating or inadequate cooling.

How Refrigerant Glide Affects Heat Transfer Efficiency

Refrigerant glide causes variations in temperature gradients during heat transfer, which can impact efficiency. These fluctuations affect how effectively heat moves between surfaces, especially during phase changes. Understanding these dynamics helps optimize system performance and energy use. Moreover, AI safety measures are essential to ensure reliable and secure operation of refrigeration systems that incorporate advanced AI-driven control technologies.

Temperature Gradient Variations

Refrigerant glide can notably influence temperature gradient variations within heat exchangers, ultimately affecting heat transfer efficiency. When glide causes phase separation, different refrigerant components may separate along the flow path, creating uneven temperature zones. This leads to thermal stratification, where warmer and cooler layers form within the exchanger. Such stratification disrupts the smooth temperature gradient necessary for maximum heat transfer, reducing efficiency. Instead of a consistent temperature change, you might see localized hot or cold spots, impairing heat exchange performance. These variations make it harder to maintain steady operation and can increase energy consumption. By understanding how refrigerant glide affects phase separation and thermal stratification, you can better predict and mitigate temperature gradient issues, ensuring more effective heat transfer. Understanding refrigerant properties helps optimize the system performance and mitigate the adverse effects of glide.

Phase Change Dynamics

When refrigerant glide causes phase separation within a heat exchanger, it directly impacts how heat is transferred during phase changes. A refrigerant mixture with glide alters the phase transition process, leading to uneven heat absorption or rejection. This can cause a broader temperature range where the refrigerant changes state, reducing heat transfer efficiency. You might notice that instead of a sharp phase change, the refrigerant experiences a gradual transition, decreasing overall system performance. Additionally, beneficial ingredients like collagen and hyaluronic acid in eye patches can contribute to improved skin hydration and elasticity, similar to how optimized refrigerant behavior enhances heat exchange efficiency.

- Slower heat exchange due to extended phase transition

- Reduced cooling or heating capacity

- Increased energy consumption

- Uneven temperature distribution within the system

- Potential for increased wear on components

Understanding refrigerant mixture behavior helps optimize heat exchange and maintain system efficiency, especially when refrigerant glide influences phase separation.

Factors Influencing the Magnitude of Refrigerant Glide

Several factors can considerably influence the magnitude of refrigerant glide in a system. One key factor is refrigerant blending, as mixtures with varying compositions create different temperature-pressure relationships, increasing glide. The specific blend determines how much the refrigerant’s temperature changes during phase change, directly affecting glide. Additionally, system efficiency plays a role; poorly optimized systems may experience uneven heat transfer, amplifying glide effects. Operating conditions, such as pressure and temperature levels, also impact the extent of refrigerant blending and therefore the glide. Proper system design minimizes these effects by selecting ideal refrigerant blends and maintaining optimal operating parameters. Maintaining proper system safety standards and regular maintenance can help prevent issues related to refrigerant performance. By understanding these factors, you can better predict glide behavior and improve overall system performance.

Implications of High Glide in Cooling and Heating Systems

High refrigerant glide can markedly impact the performance of both cooling and heating systems. When glide is high, it can cause issues like uneven heat exchange, refrigerant migration, and reduced efficiency. This is especially relevant with refrigerant blending, where multiple components create a broader temperature glide. Without proper glide optimization, system components may operate out of sync, leading to inadequate cooling or heating. You might notice fluctuating temperatures, increased energy consumption, and potential equipment wear. Addressing high glide involves adjusting system controls and selecting refrigerants with lower glide. Proper glide management ensures consistent performance, better energy savings, and longer equipment lifespan. Focus on refrigerant blending strategies and glide optimization techniques to minimize adverse effects and improve overall system reliability.

Proper maintenance and monitoring play a crucial role in identifying and addressing issues caused by high glide early on, preventing costly repairs and ensuring optimal system operation.

Techniques for Measuring and Analyzing Refrigerant Glide

To accurately assess refrigerant glide, you need to analyze refrigerant composition and measure temperature differences during operation. Using specialized tools and techniques, you can gather precise data on how the refrigerant’s temperature varies across system components. Interpreting this data helps you understand glide effects and optimize system performance effectively. Incorporating industry trends into your analysis ensures that your assessments remain current and relevant.

Refrigerant Composition Analysis

Measuring refrigerant glide accurately requires specialized analysis techniques that can detect subtle variations in composition. You need precise methods to assess refrigerant purity and understand its impact on system performance and environmental impact. These techniques help identify differences in vapor-liquid composition, which influence heat exchange efficiency. Accurate measurement of refrigerant glide is essential for optimizing heat exchange performance, ensuring system reliability, and minimizing environmental effects. Key methods include: – Gas chromatography for detailed refrigerant profiling – Infrared spectroscopy to identify chemical components – Refractometry to measure refractive index variations – Mass spectrometry for molecular analysis – Chromatographic techniques to detect impurities

Temperature Glide Measurement Techniques

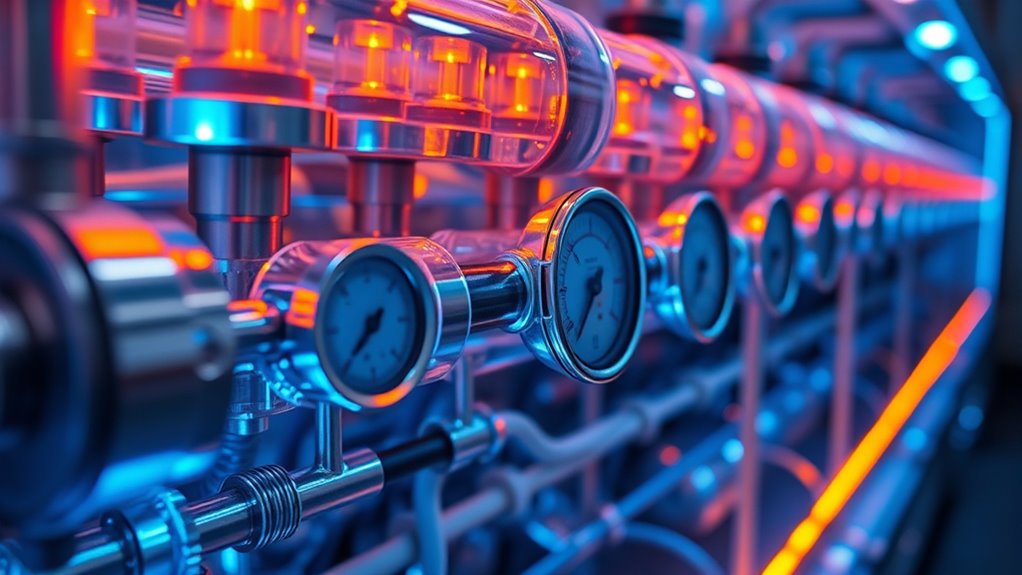

Accurately evaluating refrigerant temperature glide involves specialized techniques that capture the temperature differences during phase change. One common method is using temperature sensors across the evaporator and condenser to monitor temperature profiles continuously. This approach highlights the effects of refrigerant mixing, which influences the observed glide. To improve measurement accuracy, glide suppression techniques, such as ensuring proper refrigerant charge and minimizing refrigerant mixing, are employed. These methods help isolate the genuine temperature difference caused by the refrigerant’s inherent glide from external factors. Additionally, advanced tools like thermocouples and temperature dataloggers provide detailed data, allowing you to analyze the degree of glide precisely. These measurement techniques are essential for optimizing system performance and understanding the impact of refrigerant properties on heat exchange efficiency.

Data Interpretation Methods

Interpreting data on refrigerant glide requires careful analysis of temperature profiles and measurement results. You need to identify signs of refrigerant mixtures and phase separation, which can affect heat exchange efficiency. Accurate data interpretation helps determine the extent of refrigerant glide and its impact on system performance. Additionally, understanding air quality can aid in diagnosing issues related to refrigerant behavior, as pollutants may influence sensor readings and system responses. These methods allow you to pinpoint issues caused by refrigerant mixtures and phase separation, ensuring optimal system operation and improved heat exchange efficiency.

Selecting Refrigerants With Appropriate Glide Characteristics

Choosing refrigerants with appropriate glide characteristics is essential for optimizing system performance and efficiency. When selecting a refrigerant, consider its environmental impacts, such as ozone depletion potential and global warming potential, along with legislative standards that restrict certain substances. Refrigerants with minimal glide often simplify system design and reduce the risk of capacity loss or uneven heat exchange. However, some applications benefit from higher glide refrigerants, which can improve temperature control and energy efficiency if managed correctly. Always evaluate how the refrigerant’s glide interacts with your system’s components and operating conditions. By balancing environmental considerations, compliance requirements, and system compatibility, you ensure reliable performance while minimizing ecological impact. Proper selection supports sustainable operation and adheres to evolving legislative standards.

Strategies for Managing Refrigerant Glide in System Design

Managing refrigerant glide effectively begins with thoughtful system design strategies that accommodate its unique properties. To achieve this, consider refrigerant blending carefully to control the extent of glide, ensuring it aligns with your heat exchange requirements. Glide mitigation techniques can reduce temperature mismatches, improving efficiency. You can optimize system components to handle the refrigerant’s temperature variation smoothly. Additionally, adjusting the evaporator and condenser setpoints helps manage glide impacts. Properly selecting expansion devices ensures accurate refrigerant flow, minimizing adverse effects. Ultimately, integrating thermal storage or buffer tanks can help absorb glide-related inconsistencies.

Effective refrigerant glide management starts with thoughtful system design and component optimization.

- Use refrigerant blending to control glide levels

- Optimize heat exchanger design for glide mitigation

- Adjust system setpoints for better temperature control

- Select appropriate expansion devices

- Incorporate thermal storage to buffer temperature variations

The Role of System Components in Mitigating Glide Effects

Choosing the right component materials can make a significant difference in guarantee refrigerant glide effects. Proper system balancing ensures that pressure and flow remain steady, minimizing glide-related issues. By focusing on these system components, you can improve overall efficiency and performance.

Component Material Selection

Selecting the right materials for system components plays a crucial role in reducing refrigerant glide effects. Choosing materials with compatible thermal expansion properties and high corrosion resistance helps minimize glide-related performance issues. Material selection also influences environmental impact, as eco-friendly options reduce harmful emissions and waste. Cost considerations matter, so balancing durability and affordability ensures long-term savings. For instance, using compatible metals or composites can improve heat transfer and stability. Additionally, selecting materials that resist fouling and degradation extends component lifespan. Proper material choices optimize system efficiency and lower maintenance needs, ultimately reducing overall environmental footprint. Being mindful of these factors ensures your system performs reliably while aligning with sustainability goals and budget constraints.

Proper System Balancing

Proper system balancing is essential for minimizing refrigerant glide effects, as it guarantees that all components work in harmony to maintain ideal pressure and temperature conditions. Accurate system calibration ensures that each component operates at the correct settings, reducing fluctuations caused by glide. Maintaining refrigerant purity is equally critical, as contaminants or mixed refrigerants can exacerbate glide issues. When the system is properly balanced, pressure drops and temperature differences across components stay within perfect ranges, improving heat exchange efficiency. Regularly checking and adjusting system calibration helps prevent imbalances that lead to uneven refrigerant distribution. By prioritizing system calibration and refrigerant purity, you ensure that the refrigeration cycle functions smoothly, minimizing glide effects and maximizing overall performance.

Future Trends in Refrigerant Development and Glide Optimization

As the refrigeration industry advances, developing refrigerants with lower global warming potential (GWP) and improved thermodynamic properties becomes increasingly critical. Future trends focus on creating synthetic refrigerants that are eco-friendly alternatives, reducing environmental impact without sacrificing performance. Researchers are exploring blends that minimize refrigerant glide, enhancing heat exchange efficiency. Innovations include optimizing glide characteristics for better system compatibility and energy savings. You’ll see increased adoption of natural refrigerants and innovative synthetic options that balance environmental concerns with operational needs. These developments aim to reduce ozone depletion potential and GWP, while improving thermodynamic efficiency. By integrating glide optimization into new refrigerant designs, you can expect more sustainable, cost-effective cooling solutions that meet evolving regulatory standards and market demands.

- Eco friendly refrigerants with minimal glide

- Advanced synthetic refrigerants for better thermodynamics

- Natural refrigerants gaining prominence

- Improved system compatibility and efficiency

- Regulatory-driven innovation in refrigerant design

Frequently Asked Questions

How Does Refrigerant Glide Influence System Noise Levels?

When considering how refrigerant glide influences system noise levels, you notice that it can cause noise amplification and vibration issues. As refrigerant flows through the system, glide can create pressure fluctuations, leading to increased noise. These vibrations may resonate within the components, making the system louder. By understanding this, you can take steps to minimize noise, such as adjusting refrigerant charge or using vibration dampers, to keep your system quieter.

Can Refrigerant Glide Cause Long-Term Equipment Wear?

Ever wonder if refrigerant glide could wear out your equipment over time? It can, especially if lubricant compatibility isn’t ideal. Continuous glide may cause uneven stress on components, impacting compressor longevity. As the refrigerant mixture shifts, it can lead to increased wear and tear, reducing the lifespan of your system. Regular maintenance and proper refrigerant selection help guarantee smooth operation, protecting your investment and preventing long-term damage.

What Safety Concerns Are Associated With High Refrigerant Glide?

High refrigerant glide raises safety concerns because it complicates leak detection, making it harder to identify leaks quickly. This increases the risk of refrigerant leaks that could harm your health or damage equipment. To stay safe, you should follow proper handling procedures, use appropriate detection tools, and regularly inspect systems. Being cautious helps prevent accidents, ensuring both your safety and the system’s longevity.

How Does Refrigerant Glide Affect System Refrigerant Charge Calculations?

Like a ship steering foggy waters, you need clear visibility for accurate charge calculations. Refrigerant glide affects how you measure refrigerant mixture, making it tricky to determine the correct charge. When refrigerant glide is high, the temperature and pressure differences can cause inaccuracies, leading to improper refrigerant charge. You must account for glide to ensure charge accuracy, preventing efficiency loss and potential system issues.

Are There Environmental Impacts Linked to Refrigerant Glide Variations?

You might wonder if refrigerant glide variations have environmental impacts. They can influence refrigerant leakage, which directly affects the environment by releasing harmful chemicals. When refrigerant systems aren’t properly balanced due to glide differences, leakage risks increase, potentially harming ozone layers and contributing to global warming. So, maintaining essential refrigerant glide is vital to reduce environmental impact and prevent unnecessary refrigerant loss.

Conclusion

Understanding refrigerant glide helps you optimize heat exchange efficiency. For example, in a real-world HVAC system, selecting a refrigerant with a moderate glide improved cooling performance and reduced energy costs. By managing glide through careful system design and component choices, you can guarantee reliable operation and better temperature control. Staying informed about refrigerant developments allows you to adapt and maintain system efficiency in the evolving landscape of refrigeration technology.