Controlling subcooling and superheating is essential for your heat pump’s efficiency and longevity. Proper subcooling ensures more liquid refrigerant enters the expansion device, boosting heat transfer, while adequate superheating prevents liquid from reaching the compressor, avoiding damage. Both parameters help optimize system performance and energy use. Maintaining the right balance can save you energy and reduce operating costs. By understanding these processes, you’ll enhance your heat pump’s reliability and efficiency—discover more about how to fine-tune these critical settings.

Key Takeaways

- Proper subcooling maximizes heat absorption in the evaporator, enhancing heat pump efficiency.

- Adequate superheating prevents liquid refrigerant from damaging the compressor, ensuring system longevity.

- Balancing subcooling and superheating optimizes refrigerant state for better energy transfer.

- Monitoring these parameters allows fine-tuning for improved performance and reduced operating costs.

- Correct management of subcooling and superheating leads to more reliable, energy-efficient heat pump operation.

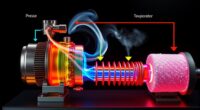

Have you ever wondered how refrigeration systems control temperature with such precision? It all comes down to the careful management of refrigerant properties and how they influence system efficiency. Subcooling and superheating are critical processes that ensure your heat pump runs smoothly and effectively. When refrigerant is subcooled, it’s cooled below its boiling point at a given pressure. This extra cooling means more liquid refrigerant enters the expansion device, which improves the system’s efficiency by optimizing the amount of refrigerant that evaporates in the coil. Conversely, superheating involves heating the refrigerant vapor above its boiling point after it has evaporated. Proper superheating guarantees that only vapor, not liquid, reaches the compressor, preventing potential damage. Both processes serve to fine-tune the refrigerant’s state, directly impacting performance and longevity. Additionally, understanding the pressure-temperature relationships of refrigerants helps technicians make precise adjustments to optimize system operation.

Understanding refrigerant properties is essential to grasp how subcooling and superheating influence system efficiency. Each refrigerant has specific boiling points, heat capacities, and pressure-temperature relationships. When you maintain proper subcooling levels, you’re ensuring that the refrigerant’s temperature is just right for maximum heat absorption in the evaporator. This not only enhances energy transfer but also minimizes waste, making the system more efficient. Likewise, controlling superheating helps you avoid compressor damage by ensuring only vapor enters the compressor. If superheating is too low, liquid refrigerant might reach the compressor, risking failure. If it’s too high, the system wastes energy heating refrigerant unnecessarily. Proper management involves balancing these states according to the refrigerant’s properties, which varies depending on the specific type used.

Achieving the right levels of subcooling and superheating involves careful measurement and adjustment. When you monitor the temperature difference across the condenser and evaporator, you can fine-tune system components to optimize performance. For example, increasing subcooling might involve adjusting the expansion valve or installing a receiver to store excess liquid, ensuring the refrigerant enters the expansion device at the ideal temperature. Superheating adjustments often include modifying the evaporator’s refrigerant flow or using thermostatic expansion valves that respond to the refrigerant vapor’s temperature. These adjustments are crucial because they directly influence how effectively your heat pump transfers heat, conserving energy and reducing operating costs.

Frequently Asked Questions

How Do Subcooling and Superheating Affect Energy Efficiency?

Subcooling and superheating considerably impact your heat pump’s energy efficiency by optimizing refrigerant flow. When you maintain appropriate subcooling, you guarantee the refrigerant absorbs maximum heat, reducing energy waste. Proper superheating prevents refrigerant vapor from entering the compressor, protecting it and improving cycle efficiency. By fine-tuning these factors, you enhance overall performance, lower energy consumption, and achieve better temperature control, making your system more effective and cost-efficient.

Can Improper Subcooling or Superheating Cause System Damage?

Improper subcooling or superheating can cause system malfunctions or refrigerant leaks. For example, just a 5% deviation can lead to compressor damage, risking costly repairs. When these parameters are off, it stresses components, increasing the likelihood of system failure. You should regularly check and adjust subcooling and superheating to prevent damage, ensuring your heat pump operates efficiently and reliably without risking leaks or breakdowns.

What Are Typical Subcooling and Superheating Setpoints for Heat Pumps?

You should aim for subcooling setpoints around 8-12°F and superheating between 8-12°F for ideal heat pump performance. These setpoints depend on refrigerant selection and system capacity, so always refer to manufacturer guidelines. Properly maintained subcooling and superheating ensure efficiency, prevent damage, and maximize lifespan. Regularly monitor and adjust these parameters to match your specific system to keep it running smoothly.

How Do Environmental Conditions Influence Subcooling and Superheating Levels?

Environmental conditions greatly impact subcooling and superheating levels. For example, when ambient temperature rises above 95°F, you might see superheating increase by up to 10%. High humidity levels can also reduce subcooling efficiency, as moisture affects refrigerant condensation. You’ll notice these changes more during hot or humid days, so adjusting your system or maintaining proper setpoints becomes essential to keep your heat pump running efficiently.

Are There Specific Tools Needed to Measure Subcooling and Superheating Accurately?

You’ll need a good set of HVAC gauges to measure subcooling and superheating accurately, as they help you monitor refrigerant properties effectively. A digital or analog manifold gauge set allows precise readings, which are essential for compressor diagnostics and ensuring best heat pump performance. Using these tools, you can identify refrigerant issues early, maintain proper system operation, and troubleshoot problems related to refrigerant flow and heat exchange.

Conclusion

Just as a skilled sailor reads the winds to navigate smoothly, understanding subcooling and superheating guides your heat pump’s efficiency. When you master these concepts, you guarantee ideal performance and energy savings—like a captain steering confidently through calm waters. Remember, paying attention to these details keeps your system running at its best, preventing surprises along the way. Embrace the knowledge, and your heat pump will serve you reliably, much like a trusty ship on a steady course.