Variable speed compressors optimize the refrigeration cycle by adjusting their motor speed to match your cooling needs precisely. This means they avoid overcooling or undercooling, leading to better temperature control and increased efficiency. They ramp up quickly during high demand and slow down when less cooling is needed, which reduces energy waste and extends equipment life. To discover more about how these advanced units can benefit your system, keep exploring the details below.

Key Takeaways

- Adjust compressor speed to precisely match cooling demand, preventing overcooling and undercooling.

- Improve energy efficiency by only using necessary power during varying load conditions.

- Enhance temperature regulation, maintaining stable conditions and product quality.

- Reduce mechanical wear and extend equipment lifespan through smoother operation.

- Enable system flexibility and better integration with building management systems for optimized performance.

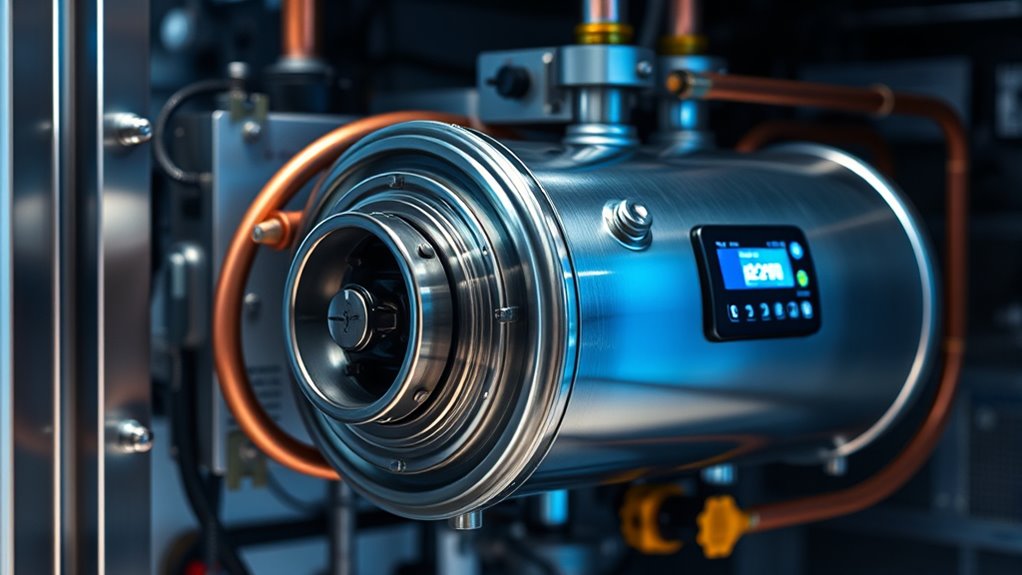

Variable speed compressors are transforming refrigeration systems by allowing precise control over cooling capacity. Instead of running at a fixed speed, these compressors can adjust their motor speed to match the cooling demand exactly. This flexibility means you can avoid overcooling or undercooling, leading to more efficient operation. As a result, you experience significant energy savings because the compressor only uses as much power as needed at any given moment. When the load decreases, the compressor slows down, consuming less energy. Conversely, during peak demands, it ramps up quickly to maintain consistent temperatures. This dynamic adjustment keeps your refrigeration system running at its best, reducing wasteful energy consumption common with traditional fixed-speed units.

The system’s flexibility is one of the key advantages of variable speed compressors. They provide better control over temperature fluctuations, which is especially crucial in environments where precise cooling is essential, like food storage or pharmaceuticals. You can fine-tune the system to maintain a stable temperature, improving product quality and shelf life. Additionally, because the compressor adapts to changing conditions, it reduces wear and tear on system components. This not only extends the lifespan of your equipment but also lowers maintenance costs over time. The ability to modulate the compressor’s speed also means you can implement smarter control strategies, integrating with advanced building management systems to optimize overall energy use. Incorporating advanced filtration and other technologies can further enhance system efficiency and air quality in related settings.

In addition, the increased system flexibility offered by variable speed compressors allows for better integration with other refrigeration components. You can coordinate multiple units to work together more efficiently, balancing loads across systems and avoiding sudden surges in power. This adaptability makes it easier to design scalable refrigeration solutions that grow with your needs. Plus, because these compressors operate more smoothly and quietly, they contribute to a more comfortable environment and reduce noise pollution.

Frequently Asked Questions

How Do Variable Speed Compressors Impact Energy Consumption?

Variable speed compressors markedly reduce your energy consumption by adjusting their output based on the cooling load. This load adaptability ensures they operate only as hard as needed, avoiding unnecessary energy use. As a result, your system becomes more energy-efficient, saving you money and reducing environmental impact. By maintaining precise temperature control, these compressors optimize the refrigeration cycle, making your cooling system more effective and sustainable over time.

Are Variable Speed Compressors Cost-Effective for Small-Scale Refrigeration Systems?

Sure, investing in variable speed compressors for small-scale systems is like buying a luxury yacht for a bathtub—probably not cost-effective. A thorough cost analysis shows they can save energy long-term, but installation considerations like compatibility and upfront costs matter. If your refrigeration needs fluctuate, they might pay off, but for steady, small loads, simpler, cheaper options often suffice. Think twice before upgrading; sometimes, basic still gets the job done.

What Maintenance Is Required for Variable Speed Compressors?

You need to regularly check lubrication requirements to ensure smooth operation and prevent wear. Keep an eye on vibration monitoring to detect any abnormal vibrations early, which could indicate issues. Lubricate moving parts as recommended by the manufacturer, and perform routine inspections for leaks or unusual noises. Proper maintenance helps extend the compressor’s lifespan, maintain efficiency, and avoid costly repairs, so stay proactive with these essential tasks.

How Do Variable Speed Compressors Respond to Sudden Load Changes?

Ever wondered how your compressor handles sudden load fluctuations? When load changes abruptly, your variable speed compressor quickly adjusts its motor speed to maintain system stability. This rapid response minimizes pressure swings and temperature variations, ensuring ideal operation. By efficiently adapting to load fluctuations, it prevents system stress and maintains consistent cooling. In summary, your compressor’s ability to respond swiftly keeps the refrigeration cycle smooth and reliable, even during unexpected demand spikes.

What Are the Common Challenges in Implementing Variable Speed Compressor Technology?

You face challenges like constant tuning to keep the compressor running efficiently and noise mitigation to prevent disturbance. Ensuring proper control algorithms and compatible components can be complex, requiring ongoing adjustments. Additionally, integrating variable speed compressors into existing systems might need upgrades, increasing costs. Managing these aspects effectively helps optimize performance, reduce energy consumption, and maintain system reliability.

Conclusion

So, next time your refrigeration system hums along with surprising efficiency, thank the magic of variable speed compressors. They cleverly adapt to your cooling needs, proving that technology can be both smart and subtle—unlike those old clunkers that wasted energy and your patience. Who knew that a tiny bit of variability could revolutionize refrigeration? It’s almost like giving your system a brain—if that brain was obsessed with saving energy while making your life cooler.