At our company, we recognize the critical need for routine maintenance on commercial heat pumps. By maintaining these vital systems, we ensure they operate at their best and last longer.

In this article, we will delve into the key components of a heat pump and provide detailed instructions on how to:

- Clean and inspect filters

- Check and repair refrigerant levels

- Lubricate moving parts

- Inspect and clean coils

Additionally, we will cover:

- Testing and calibrating the thermostat

- Ensuring proper airflow.

These maintenance tasks are crucial for the efficient operation of heat pumps and can help prevent costly breakdowns and repairs. By following these steps, you can ensure that your heat pump continues to provide reliable heating and cooling for your commercial space.

Key Takeaways

- Regular maintenance is crucial for optimal performance and longevity of commercial heat pumps.

- Neglecting maintenance can lead to reduced heating and cooling capacity, decreased energy efficiency, and increased risk of breakdowns.

- Cleaning and inspecting filters is vital for optimal performance and indoor air quality.

- Checking and repairing refrigerant levels, lubricating moving parts, and inspecting and cleaning coils are essential for maintaining the efficiency and performance of commercial heat pumps.

Importance of Regular Maintenance

We can’t underestimate the importance of regular maintenance in ensuring the optimal performance and longevity of commercial heat pumps.

Neglecting maintenance can have a significant negative effect on the overall efficiency and reliability of these systems. Without regular maintenance, heat pumps can experience reduced heating and cooling capacity, decreased energy efficiency, and increased risk of breakdowns and costly repairs.

By implementing a routine maintenance schedule, businesses can’t only prevent these issues but also achieve substantial cost savings in the long run. Regular maintenance allows technicians to identify and address potential problems early on, preventing major breakdowns and the need for expensive repairs. Additionally, it helps to optimize the energy efficiency of the heat pump, reducing energy consumption and lowering utility bills.

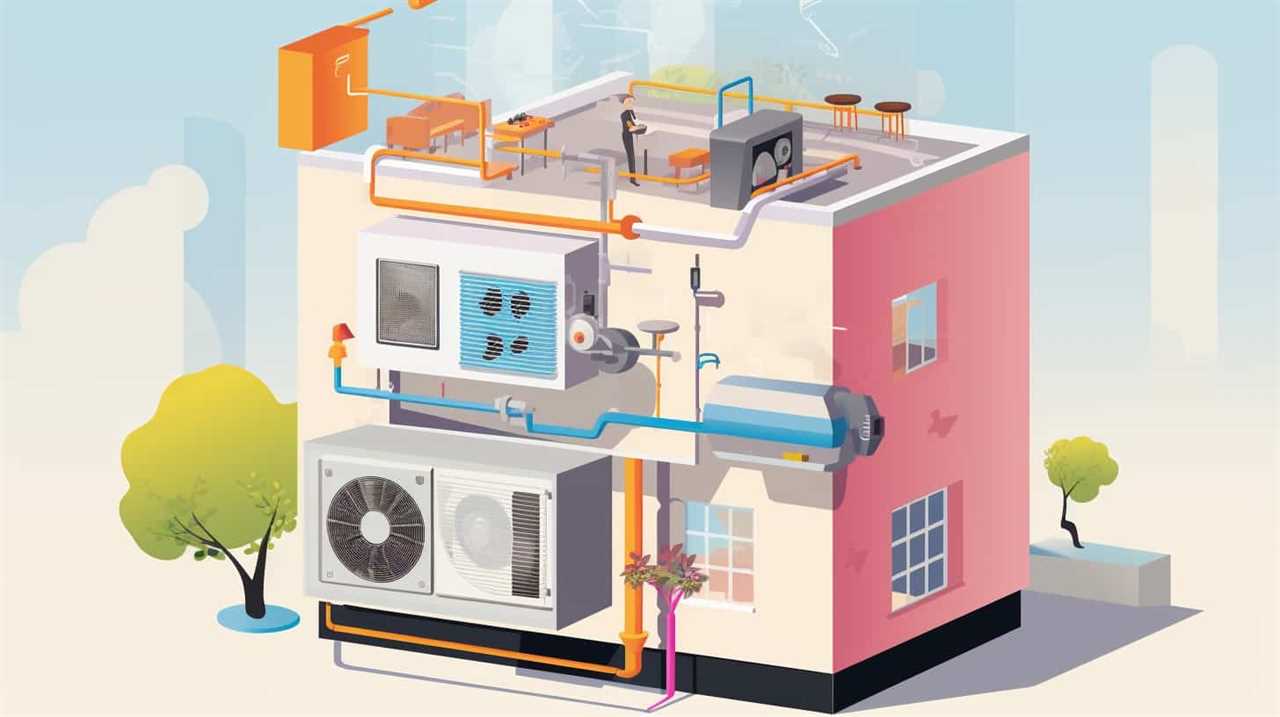

Understanding Heat Pump Components

To fully comprehend the functioning of a heat pump, it’s crucial to understand its various components and how they work together. Here are the key components of a heat pump system:

-

Evaporator Coil: This component absorbs heat from the surrounding air or water, allowing it to evaporate the refrigerant.

-

Compressor: The compressor increases the pressure and temperature of the refrigerant, ensuring efficient heat transfer.

-

Condenser Coil: As the refrigerant is compressed, it releases heat into the surrounding air or water through the condenser coil.

-

Expansion Valve: This valve regulates the flow of the refrigerant, allowing it to expand and cool down before entering the evaporator coil.

Understanding these components is essential for heat pump installation and troubleshooting common issues. By knowing how each part functions, maintenance technicians can effectively diagnose and resolve any problems that may arise, ensuring optimal performance and longevity of the heat pump system.

Cleaning and Inspecting Filters

Regularly cleaning and inspecting the filters is a vital aspect of commercial heat pump maintenance. Proper filter maintenance ensures optimal performance and efficiency of the heat pump system. Filters play a crucial role in trapping dirt, dust, and other airborne particles, preventing them from circulating through the system. Over time, these filters can become clogged with debris, obstructing airflow and reducing the heat pump’s ability to heat or cool effectively. To maintain the filters, start by turning off the heat pump and removing the filter cover. Gently remove the filters and inspect them for any signs of damage. Next, clean the filters by gently tapping them to remove loose debris, or by using a vacuum cleaner on a low suction setting. If the filters are heavily soiled, consider washing them with mild soap and water. Once cleaned, allow the filters to dry thoroughly before reinstalling them. Regularly cleaning and inspecting the filters will not only improve the heat pump’s performance but also contribute to cleaner indoor air quality.

The following table provides a quick guide on proper filter maintenance and removing debris:

| Task | Frequency |

|---|---|

| Inspect filters | Monthly |

| Clean filters | Every 1-3 months |

| Replace filters | Every 3-6 months |

| Remove debris | As needed |

Checking and Repairing Refrigerant Levels

Let’s check and repair the refrigerant levels to ensure optimal performance of the commercial heat pump system. It’s important to monitor the refrigerant levels regularly to prevent any potential issues that may arise from refrigerant leakage. Troubleshooting refrigerant issues is crucial in maintaining the efficiency and longevity of the heat pump system.

Here are some key steps to follow:

- Conduct a visual inspection of the refrigerant lines for any signs of leakage, such as oil stains or frost accumulation.

- Use a refrigerant gauge to measure the pressure and temperature of the refrigerant in the system.

- Compare the readings with the manufacturer’s specifications to determine if the refrigerant levels are within the recommended range.

- If the levels are low, locate and repair the source of the leakage, and then recharge the system with the appropriate amount of refrigerant.

By addressing refrigerant issues promptly, you can ensure that your commercial heat pump system operates at its best.

Now, let’s move on to the next section about lubricating moving parts.

Lubricating Moving Parts

We should regularly inspect and lubricate the moving parts of the commercial heat pump system to ensure smooth and efficient operation. Lubricating the moving parts is of utmost importance as it reduces friction and wear, helping to prolong the lifespan of the heat pump. The lubricant forms a protective layer that prevents metal-to-metal contact and minimizes heat generation. This not only ensures the smooth operation of the heat pump but also improves its energy efficiency.

When it comes to lubricants, there are several types available, including mineral oil, synthetic oil, and grease. The choice of lubricant depends on factors such as temperature, load, and speed. It’s essential to consult the manufacturer’s recommendations and guidelines to select the appropriate lubricant for each specific component of the heat pump system.

Regular lubrication and maintenance of the moving parts are vital for the optimal performance and longevity of the commercial heat pump system.

Inspecting and Cleaning Coils

Now let’s turn our attention to the crucial task of inspecting and cleaning the coils in commercial heat pumps.

Proper coil maintenance is essential for optimal heat pump performance and energy efficiency. To ensure the coils are functioning effectively, it’s important to regularly inspect them for any signs of dirt, debris, or damage.

Cleaning techniques such as using a soft brush or compressed air can be employed to remove any build-up and ensure the coils are clean and free from obstructions.

Coil Maintenance Importance

Inspecting and cleaning coils is crucial for ensuring the proper functioning and longevity of commercial heat pumps. Regular maintenance of coils is essential to prevent issues such as reduced heat transfer efficiency, increased energy consumption, and potential system breakdowns. Here are some key reasons why coil maintenance is important:

- Efficient heat transfer: Clean coils allow for optimal heat transfer between the refrigerant and the surrounding air, maximizing the heat pump’s efficiency and performance.

- Energy savings: Dirty coils increase the workload on the heat pump, resulting in higher energy consumption and increased operating costs.

- Extended equipment lifespan: By keeping coils clean and free of debris, you can prevent unnecessary wear and tear on the heat pump, extending its lifespan.

- Improved indoor air quality: Clean coils help remove pollutants from the air, ensuring a healthier and more comfortable indoor environment.

To properly maintain coils, it’s important to employ effective coil cleaning techniques and promptly troubleshoot any coil issues that may arise. Regular inspections and cleanings should be conducted by trained professionals to ensure optimal performance and reliability of commercial heat pumps.

Cleaning Techniques for Coils

Regular maintenance of coils includes thorough cleaning to remove dirt, debris, and contaminants, improving the overall efficiency and performance of commercial heat pumps. Cleaning the coils is an essential part of coil maintenance, as dirty coils can lead to reduced airflow and poor heat transfer.

There are several effective coil cleaning techniques that can be used to ensure optimal performance. One commonly used technique is using a coil cleaner solution that’s specifically designed for removing dirt and debris from the coils. This solution is applied to the coils and left to penetrate and dissolve the contaminants. Afterward, the coils are rinsed thoroughly with water to remove any remaining residue.

Another technique is using a coil brush to manually scrub the coils and remove stubborn dirt and debris. This can be done in combination with a coil cleaner solution for enhanced cleaning.

Regular coil cleaning should be performed at least twice a year to maintain the efficiency and longevity of the commercial heat pump.

Testing and Calibrating Thermostat

Have we properly tested and calibrated the thermostat? This is a crucial step in ensuring the optimal performance of a commercial heat pump system.

Neglecting to test and calibrate the thermostat can lead to inefficient heating or cooling, resulting in higher energy consumption and discomfort for occupants.

Here are some important considerations when troubleshooting and programming the thermostat:

-

Check the thermostat’s power source and ensure it’s properly connected.

-

Verify that the thermostat is correctly programmed with the desired temperature settings.

-

Conduct a temperature differential test to determine the accuracy of the thermostat’s temperature readings.

-

Calibrate the thermostat if necessary to ensure accurate temperature control.

Ensuring Proper Airflow

To maintain optimal performance, we must ensure that proper airflow is maintained in a commercial heat pump system. Proper airflow is crucial for improving efficiency and preventing system failure. When airflow is restricted or inadequate, the heat pump has to work harder to achieve the desired temperature, leading to increased energy consumption and potential equipment damage. To prevent these issues, regular maintenance is essential. This includes inspecting and cleaning the air filters, ensuring that the ductwork is free from obstructions, and checking the fan blades for any damage or debris accumulation. Additionally, it is important to check the balance of airflow throughout the system and make any necessary adjustments. By prioritizing proper airflow, you can maximize the efficiency of your commercial heat pump system and avoid costly repairs.

| Key Considerations | Benefits |

|---|---|

| Clean air filters | Enhanced system efficiency |

| Obstruction-free ductwork | Prevents system failure |

| Damage-free fan blades | Improved energy consumption |

| Balanced airflow | Minimizes equipment damage |

Frequently Asked Questions

How Often Should Commercial Heat Pumps Be Professionally Inspected and Maintained?

We recommend that commercial heat pumps be professionally inspected and maintained at least once a year. This frequency ensures optimal performance and helps identify potential issues early on, minimizing costs for repairs and replacements.

Are There Any Specific Signs or Indicators That Suggest a Commercial Heat Pump May Need Maintenance?

Signs and indicators that suggest a commercial heat pump may need maintenance include reduced cooling or heating efficiency, unusual noises, foul odors, and frequent cycling. These specific indicators should prompt immediate attention to address maintenance needs.

Can Regular Maintenance Help Improve the Energy Efficiency of a Commercial Heat Pump?

Regular maintenance can greatly improve the energy efficiency of a commercial heat pump. Energy saving tips, such as cleaning or replacing air filters, lubricating moving parts, and checking refrigerant levels, can be done through DIY heat pump maintenance.

Are There Any Specific Safety Precautions That Should Be Taken During Commercial Heat Pump Maintenance?

During commercial heat pump maintenance, it is crucial to prioritize safety precautions. By following proper protocols and protective measures, we can ensure the well-being of both technicians and the equipment.

Is It Necessary to Hire a Professional Technician for Commercial Heat Pump Maintenance, or Can It Be Done by In-House Staff?

Hiring a professional technician for commercial heat pump maintenance is necessary for efficient and effective results. In-house maintenance may seem cost-effective initially, but professional maintenance ensures proper handling of complex equipment and avoids potential risks.

Conclusion

In conclusion, regular maintenance is essential for the optimal performance and longevity of commercial heat pumps.

By understanding the components and following the proper cleaning and inspection procedures, such as cleaning filters, checking refrigerant levels, lubricating moving parts, inspecting coils, testing the thermostat, and ensuring proper airflow, one can ensure that their heat pump operates efficiently.

Remember, a well-maintained heat pump is a reliable and cost-effective investment for any commercial space.

So, don’t overlook the importance of maintenance and keep your heat pump running smoothly for years to come.