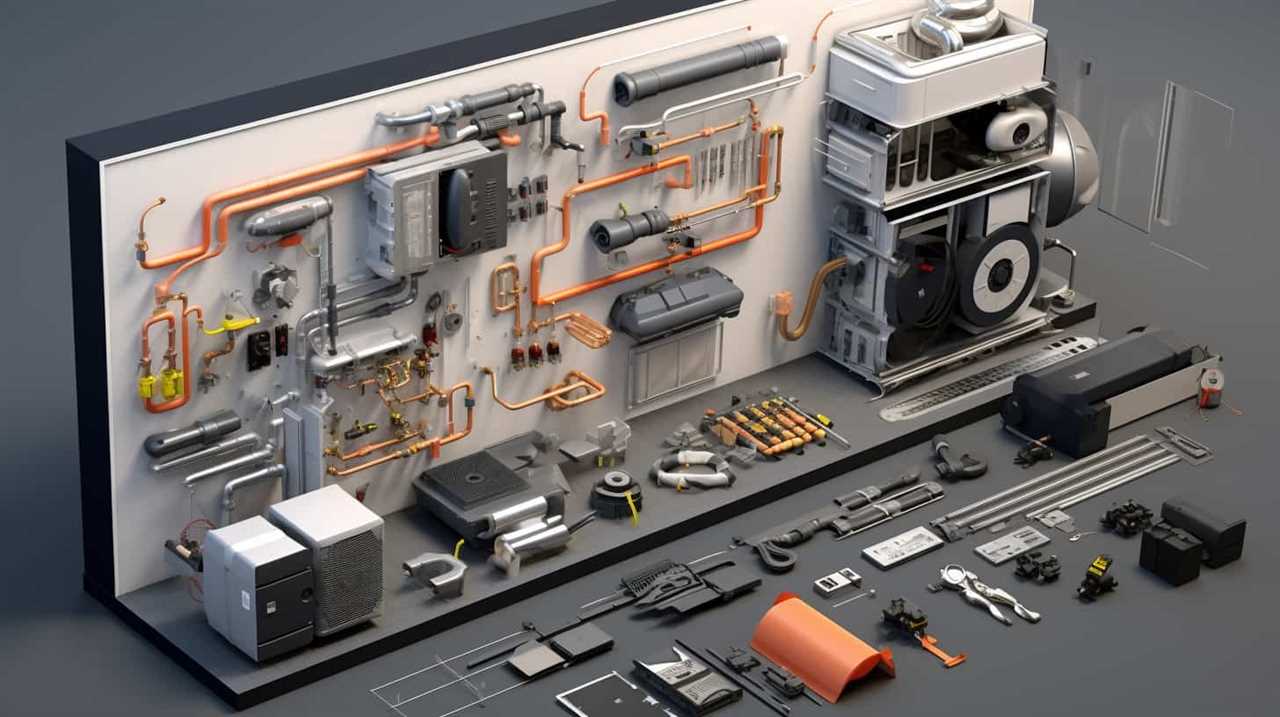

We have everything you need with the definitive checklist for maintaining commercial heat pumps. Consistent maintenance is crucial to guarantee peak functionality and prolong the life of your unit.

From cleaning and inspecting the outdoor unit to testing electrical connections, we’ll guide you through the necessary steps.

With our detailed approach, you can rest assured that your heat pump will keep serving you efficiently and reliably.

Let’s dive into the world of heat pump maintenance together.

Key Takeaways

- Regular maintenance is essential for optimal performance and energy efficiency of commercial heat pumps.

- Cleaning and inspecting the outdoor unit helps maintain optimal performance and prevent damage.

- Checking and changing air filters regularly improves indoor air quality and energy consumption.

- Testing and calibrating the thermostat ensures efficient operation of commercial heat pumps.

Importance of Regular Maintenance

Regular maintenance is important for keeping our commercial heat pumps running efficiently and avoiding costly repairs. By regularly maintaining our heat pumps, we ensure that they’re operating at peak performance, which leads to increased energy efficiency and lower utility bills.

Regular maintenance also helps to extend the lifespan of our heat pumps, reducing the need for premature replacements. Additionally, by conducting regular inspections and cleaning, we can identify and address any potential issues before they escalate into major problems. This proactive approach not only saves us money but also minimizes downtime and disruption to our operations.

Furthermore, regular maintenance allows us to maintain a comfortable and productive indoor environment for our employees and customers. Ultimately, the benefits of regular maintenance far outweigh the costs, making it a smart investment for our commercial heat pumps.

Cleaning and Inspecting the Outdoor Unit

To ensure optimal performance, we need to regularly clean and inspect the outdoor unit of our commercial heat pump. Outdoor unit maintenance is crucial for the efficient operation of the heat pump and to prevent common issues from occurring.

First, we should visually inspect the unit for any signs of damage, such as bent fins or loose connections.

Next, we need to clean the unit by removing any debris, such as leaves or dirt, from the coil fins using a soft brush or a vacuum cleaner. It’s important to avoid using high-pressure water, as it can damage the fins.

Additionally, we should check the fan motor and blades for any signs of wear or damage.

Checking and Changing Air Filters

How often should we check and change the air filters in our commercial heat pump?

Air filter maintenance is a crucial aspect of commercial heat pump maintenance. It’s recommended to check and change the air filters every three months, or more frequently if the system is located in a dusty or high-traffic area.

Regular maintenance ensures optimal performance and efficiency of the heat pump. Neglecting air filter maintenance can lead to reduced airflow, decreased indoor air quality, and increased energy consumption.

When checking the air filters, it’s important to look for signs of dirt, dust, or debris accumulation. If the filters appear dirty or clogged, it’s time for filter replacement.

Testing and Calibrating Thermostat

We can test and calibrate the thermostat to ensure accurate temperature control and efficient operation of our commercial heat pump.

Testing the thermostat involves checking if it accurately reads and responds to temperature changes. We can do this by comparing the thermostat reading with a separate thermometer. If there’s a discrepancy, we may need to recalibrate the thermostat.

Calibrating the thermostat involves adjusting its internal settings to optimize its performance and accuracy. This can be done by following the manufacturer’s instructions or consulting a professional technician.

Lubricating Moving Parts

When it comes to maintaining commercial heat pumps, lubricating moving parts is a crucial step that can’t be overlooked. Proper lubrication ensures smooth operation and reduces friction, minimizing wear and tear on the components.

It’s essential to follow the manufacturer’s guidelines for selecting the correct lubricant and applying it in the right amount. Regular lubrication should be scheduled based on the equipment’s usage and the manufacturer’s recommendations to keep the heat pump running efficiently and prolong its lifespan.

Importance of Lubrication

Lubricating the moving parts is crucial for maintaining the performance and longevity of the commercial heat pump. Proper lubrication techniques ensure that the components within the heat pump function smoothly and efficiently, reducing friction and wear.

It’s important to follow the manufacturer’s guidelines for lubrication frequency, as this can vary depending on the specific model and usage. Regular lubrication helps to prevent overheating, noise, and premature failure of the heat pump. Additionally, it improves energy efficiency by reducing the amount of power required for the pump to operate.

Neglecting lubrication can result in costly repairs and decreased lifespan of the heat pump. Therefore, it’s essential to include lubrication as a regular part of the maintenance routine to ensure optimal performance and longevity of the commercial heat pump.

Proper Lubrication Techniques

To ensure proper maintenance of commercial heat pumps, it’s essential that moving parts are lubricated using the correct techniques. Proper lubrication methods are crucial for preventing wear and tear, reducing friction, and ensuring the smooth operation of the heat pump. When it comes to choosing the right lubricant, it’s important to consider factors such as temperature range, load capacity, and compatibility with the specific components of the heat pump. Different types of lubricants, such as oils or greases, may be suitable for different parts of the heat pump. It’s advisable to consult the manufacturer’s guidelines or seek professional advice to determine the most appropriate lubricant for your specific heat pump model.

By using proper lubrication techniques and selecting the right lubricant, you can significantly prolong the lifespan of your commercial heat pump.

Speaking of maintenance, let’s now delve into the next topic: the frequency of lubrication.

Frequency of Lubrication

We should regularly lubricate the moving parts of our commercial heat pump to ensure smooth operation and prevent excessive wear and tear. Lubricating the parts is of utmost importance as it reduces friction and enhances the overall efficiency of the heat pump.

The frequency of lubrication depends on several factors such as the type of heat pump, the manufacturer’s recommendations, and the operating conditions. As a general guideline, it’s advisable to lubricate the moving parts at least once a year. However, in high-demand environments or harsh operating conditions, more frequent lubrication may be necessary.

When lubricating, it’s crucial to follow the manufacturer’s guidelines and use the recommended lubricants. This ensures optimal performance and longevity of the heat pump.

Regularly lubricating the moving parts is one of the best practices for maintaining the efficiency and reliability of our commercial heat pump.

Inspecting and Cleaning Coils

Let’s start by checking and cleaning the coils to ensure optimal performance of the commercial heat pump.

Inspecting coil efficiency is crucial in maintaining the overall efficiency of the heat pump system. Dirty or clogged coils can lead to decreased efficiency and increased energy consumption.

Begin by visually inspecting the coils for any signs of dirt, debris, or damage. Use a flashlight to check for any blockages or buildup in the coils.

If the coils appear dirty, it’s important to clean them thoroughly. This can be done by using a soft brush or a coil cleaning solution. Carefully remove any debris or dirt from the coils, taking care not to damage the delicate fins.

Regular cleaning and maintenance of the coils will ensure the longevity and efficiency of the commercial heat pump system.

Checking Refrigerant Levels

When it comes to the maintenance of commercial heat pumps, checking refrigerant levels is a crucial step. Proper refrigerant levels are essential for the efficient operation of the heat pump and ensuring optimal performance.

Common issues with refrigerant levels include leaks, overcharging, and undercharging, which can lead to decreased efficiency and potential system damage.

Proper Refrigerant Level Importance

Checking the refrigerant levels regularly is an important maintenance task for commercial heat pumps. Maintaining the proper refrigerant level ensures optimal performance and energy efficiency.

Here are five reasons why checking refrigerant levels is crucial:

-

Prevents system breakdowns: Insufficient refrigerant can cause the system to overheat and potentially lead to a breakdown.

-

Maximizes energy efficiency: Proper refrigerant levels allow the heat pump to operate at peak efficiency, saving energy and reducing utility costs.

-

Extends equipment lifespan: Adequate refrigerant levels help prevent unnecessary wear and tear, prolonging the lifespan of the heat pump.

-

Improves cooling/heating capacity: Insufficient refrigerant can result in reduced cooling or heating capacity, leading to discomfort in the building.

-

Avoids refrigerant leaks: Regularly checking refrigerant levels can help identify and address potential leaks before they become costly problems.

To troubleshoot refrigerant levels, use refrigerant level indicators, such as pressure gauges or sight glasses, to ensure the system is properly charged.

Regular maintenance and monitoring of refrigerant levels are essential for keeping commercial heat pumps running smoothly and efficiently.

Common Refrigerant Level Issues

We encounter common refrigerant level issues, and it’s important for us to regularly check and address them to maintain optimal performance in commercial heat pumps.

One of the most common issues is refrigerant leaks, which can lead to a decrease in cooling or heating efficiency and even system failure if not addressed promptly. To troubleshoot refrigerant leaks, we can perform a visual inspection of the system for any visible signs, such as oil stains or frost accumulation. Additionally, we can use electronic leak detectors or ultrasonic leak detectors to pinpoint the exact location of the leak.

Once the leak is located, we can repair it by replacing the damaged component or sealing the leak. Regularly checking refrigerant levels and addressing any issues promptly is crucial for ensuring the longevity and efficiency of commercial heat pumps.

Testing Electrical Connections

To ensure proper functioning, we should test the electrical connections of the commercial heat pump. Inspecting electrical connections is crucial in identifying any potential issues that could affect the performance of the heat pump.

Here are some important steps to follow when testing the electrical connections:

-

Check for loose or corroded connections: Loose or corroded connections can lead to poor electrical conductivity, resulting in inefficiency or even equipment failure.

-

Verify proper voltage levels: Incorrect voltage levels can cause the heat pump to malfunction or not operate at all.

-

Inspect wiring for damage: Damaged wiring can pose a safety hazard and affect the overall performance of the heat pump.

-

Test electrical components: Ensure that all electrical components, such as capacitors and relays, are functioning correctly.

-

Troubleshoot electrical issues: If any electrical problems are detected, troubleshoot them promptly to prevent further damage.

By testing the electrical connections, we can ensure that the heat pump operates efficiently and safely.

Now, let’s move on to inspecting and cleaning the drainage system.

Inspecting and Cleaning Drainage System

As part of our maintenance routine, we need to inspect and clean the drainage system to ensure proper functioning of the commercial heat pump.

The drainage system plays a crucial role in removing excess water and condensation from the heat pump, preventing the risk of water damage and maintaining optimal performance.

To begin the inspection, we carefully examine the drainage pipes, ensuring they’re free from any blockages or obstructions. If we encounter any issues, such as slow drainage or water leaks, we perform troubleshooting to identify the cause and take appropriate action.

Cleaning the drainage system involves removing any debris or buildup that may impede the flow of water.

Regular drainage system maintenance is essential to prevent potential issues and ensure the smooth operation of the commercial heat pump.

Evaluating Overall System Performance

Assessing the system’s overall performance is crucial for ensuring the optimal functioning of the commercial heat pump. Evaluating energy efficiency and troubleshooting performance issues are essential steps in this process. Here are five key factors to consider when evaluating the overall system performance:

-

Energy consumption: Analyze the heat pump’s energy usage to identify any inefficiencies or excessive power consumption.

-

Temperature differentials: Measure the temperature difference between the heated or cooled space and the supply air to ensure proper heat transfer.

-

Airflow: Check the airflow rates to ensure they meet the manufacturer’s specifications and that the heat pump is delivering the required amount of conditioned air.

-

Noise levels: Monitor noise levels to identify any abnormal sounds that may indicate mechanical issues.

-

Cycling frequency: Evaluate the frequency at which the heat pump cycles on and off to ensure it’s operating within normal parameters.

Frequently Asked Questions

How Often Should Commercial Heat Pumps Be Serviced?

We recommend regular commercial heat pump servicing to ensure optimal performance and efficiency. The frequency of maintenance depends on factors like usage and environment. Benefits of regular servicing include extended lifespan and improved energy savings.

Can Regular Maintenance Help Extend the Lifespan of a Commercial Heat Pump?

Regular maintenance of a commercial heat pump is crucial for extending its lifespan. With professional servicing and the benefits of regular maintenance, we can ensure optimal performance and prevent costly breakdowns.

What Are the Signs That a Commercial Heat Pump Requires Professional Maintenance?

Warning signs that a commercial heat pump requires professional maintenance include reduced heating or cooling efficiency, strange noises, and frequent breakdowns. Professional maintenance is important to ensure optimal performance and prevent costly repairs.

Are There Any Specific Safety Precautions to Consider When Performing Maintenance on a Commercial Heat Pump?

When performing maintenance on a commercial heat pump, it is important to follow safety precautions to ensure the well-being of both the technicians and the equipment. Additionally, adhering to recommended maintenance frequency helps maintain optimal performance and efficiency.

What Are the Potential Consequences of Neglecting Regular Maintenance for a Commercial Heat Pump?

Neglecting regular maintenance for a commercial heat pump can lead to decreased efficiency, higher energy costs, and system breakdowns. Regular maintenance is crucial as it ensures optimal performance and extends the lifespan of the heat pump.

Conclusion

In conclusion, regular maintenance is essential for ensuring the optimal performance and longevity of commercial heat pumps.

By following the ultimate checklist, which includes cleaning the outdoor unit, checking air filters, testing the thermostat, lubricating moving parts, and more, you can keep your heat pump in top shape.

Remember, a well-maintained heat pump is like a well-oiled machine, delivering efficient heating and cooling that keeps your business running smoothly.