A heat exchanger in a heat pump system transfers heat between fluids without mixing them, helping to efficiently heat or cool your space. It uses different designs like shell-and-tube or plate types to maximize contact and improve performance. Materials like copper or stainless steel resist corrosion and boost heat transfer. Proper maintenance and innovative designs can enhance system efficiency and longevity. If you’re curious, you’ll discover more about how these essential components keep your system running smoothly.

Key Takeaways

- Heat exchangers transfer thermal energy between fluids without mixing, crucial for heat pump efficiency.

- Different types like shell-and-tube and plate exchangers are designed for specific performance needs.

- Material selection impacts heat transfer rates, corrosion resistance, and system durability.

- Proper maintenance and cleaning prevent fouling and ensure optimal heat exchange performance.

- Innovations such as nanofluids and advanced coatings enhance heat transfer efficiency and system longevity.

What Is a Heat Exchanger and How Does It Function?

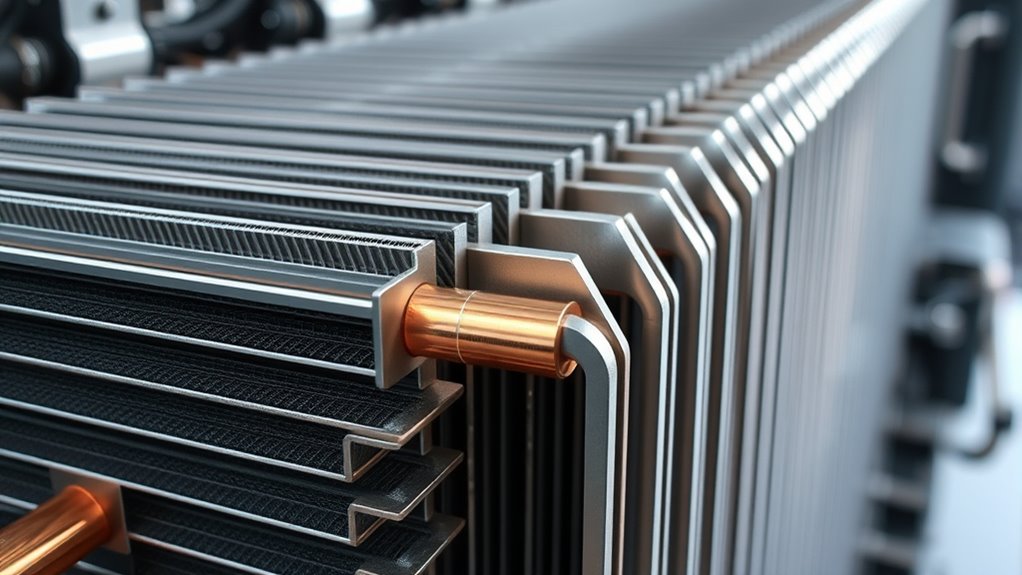

Have you ever wondered how heat is transferred efficiently in a heat pump system? It all comes down to the heat exchanger, a essential component designed to facilitate heat transfer between fluids. The heat exchanger’s design ensures maximum contact between the hot and cold fluids, optimizing heat flow. Fluid flow plays a critical role here; by directing the fluids through specific channels or plates, heat is efficiently exchanged without mixing. The process involves one fluid absorbing heat from a source, then passing it to another fluid that distributes it elsewhere. This seamless transfer relies on well-engineered heat exchanger design, which minimizes energy loss and boosts system efficiency. Properly managing fluid flow within the heat exchanger is key to maintaining effective operation in heat pump systems. Efficient heat transfer methods are crucial for maximizing system performance and energy savings.

Types of Heat Exchangers Used in Heat Pump Systems

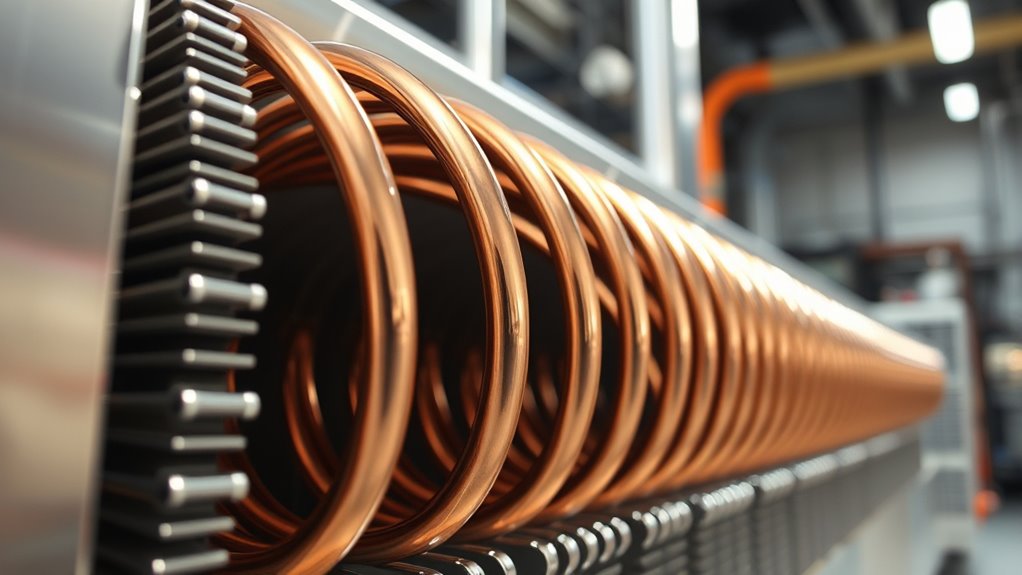

Different types of heat exchangers are employed in heat pump systems to optimize heat transfer based on application needs. Alternative heat exchanger types include shell-and-tube, plate, and coil-in-shell designs, each suited for specific heat exchanger applications. Shell-and-tube exchangers are durable and ideal for high-pressure systems, while plate heat exchangers offer high efficiency and compactness for space-constrained setups. Coil-in-shell types are flexible and used in both heating and cooling applications. Your choice depends on factors like flow rates, temperature ranges, and system size. Understanding these options helps you select the best heat exchanger for your heat pump system, ensuring optimal performance and energy efficiency tailored to your specific application needs. Material compatibility is also an important consideration when selecting a heat exchanger type to prevent corrosion and extend system longevity.

Key Components of Heat Exchangers

Understanding the key components of heat exchangers is essential for appreciating how they transfer heat efficiently. Fin heat exchangers are designed with metal fins that increase surface area, enhancing heat transfer between fluids. These fins improve efficiency, especially in air-to-refrigerant applications. Compact heat exchangers, on the other hand, feature a smaller footprint but maintain high performance through optimized surface designs and materials. Core components include the tubes or plates that carry the working fluids, along with the fins or other surfaces that facilitate heat exchange. The materials used must be thermally conductive and corrosion-resistant. Proper design and maintenance of these components guarantee maximum heat transfer, energy efficiency, and system longevity in heat pump applications. Material selection plays a critical role in ensuring durability and optimal thermal performance of heat exchangers.

The Role of Heat Exchangers in Heating and Cooling Cycles

Heat exchangers play a essential role in the heating and cooling cycles of heat pump systems by transferring thermal energy between fluids. You rely on efficient heat transfer to move heat from the outside air or ground to your indoor space or vice versa. Fluid dynamics governs how the fluids flow within the exchanger, impacting how effectively heat is exchanged. As the refrigerant absorbs or releases heat, its movement through the heat exchanger ensures ideal thermal transfer. Proper design of flow paths minimizes resistance and maximizes surface contact, enhancing performance. Without effective heat transfer and well-managed fluid dynamics, your system’s efficiency drops, and comfort levels suffer. Ultimately, heat exchangers serve as the key link that enables your heat pump to operate effectively in both heating and cooling modes.

Factors Influencing Heat Exchanger Efficiency

Your heat exchanger’s efficiency depends on several key factors. You need to contemplate the size of the heat transfer surface area, as larger surfaces improve heat exchange. Additionally, fouling and contamination can hinder performance, and optimizing flow rates helps maintain effective heat transfer. Moreover, understanding the impact of heat exchanger vulnerabilities is crucial for ensuring safety and reliability in heat pump systems.

Heat Transfer Surface Area

The efficiency of a heat exchanger largely depends on its heat transfer surface area, as a larger surface provides more contact between the two fluids, facilitating better heat exchange. To maximize this, you should focus on surface area optimization by increasing fins, plates, or tubes. Choosing the right material also impacts efficiency, as high thermal conductivity materials improve heat transfer. Consider the following factors:

| Factor | Impact | Example |

|---|---|---|

| Surface Area | Enhances heat transfer | Finned tubes |

| Material Selection | Affects thermal conductivity | Copper vs. aluminum |

| Design Geometry | Improves contact efficiency | Plate vs. shell-and-tube |

| Compactness | Reduces space, maintains area | Spiral heat exchangers |

| Maintenance | Preserves efficiency | Easy-to-clean surfaces |

Additionally, regular maintenance ensures that fouling or corrosion does not decrease the heat transfer efficiency, keeping the system operating at optimal performance.

Fouling and Contamination

Fouling and contamination can substantially reduce heat exchanger efficiency by creating an insulating layer on heat transfer surfaces. Biological fouling, such as algae or bacteria growth, can clog channels and diminish heat transfer. Chemical contamination from pollutants or reactants can form corrosive deposits, further impairing performance. To manage these issues, consider:

- Regular cleaning to remove biological growth and chemical deposits.

- Using anti-fouling coatings to inhibit biological fouling.

- Monitoring water quality to prevent chemical contamination.

- Implementing filtration systems to reduce impurity buildup.

- Selecting appropriate materials for heat exchanger components to resist corrosion and fouling.

These measures help maintain ideal heat transfer and prevent long-term damage caused by biological fouling and chemical contamination. Addressing these factors is essential for preserving heat exchanger efficiency in heat pump systems.

Flow Rate Optimization

Have you ever wondered how the flow rate of a heat exchanger affects its efficiency? Increasing the flow rate can improve heat transfer by promoting better fluid movement, but it also causes a higher pressure drop across the system. If the pressure drop becomes too large, it can reduce overall system efficiency and increase energy consumption. Conversely, a flow rate that’s too low limits heat transfer, reducing performance. To maximize, you need to balance flow rate and pressure drop carefully. Adjusting flow rate ensures maximum heat transfer without overly stressing the system. Proper flow rate optimization enhances heat exchanger efficiency, prolongs equipment life, and reduces operational costs. Regular monitoring and adjustments help you maintain ideal conditions in your heat pump system. Additionally, noise levels of modern heat pumps are designed to operate quietly, which can further improve overall comfort and system efficiency.

Common Materials and Design Considerations

Choosing the right materials for heat exchangers is vital because they must resist corrosion and efficiently transfer heat. You also need to take into account how thermal conductivity impacts performance and how structural design choices affect durability and maintenance. Balancing these factors ensures your heat pump operates reliably and efficiently over time. Additionally, understanding cheating and its effects can inform better maintenance practices and system integrity.

Material Corrosion Resistance

Why is material corrosion resistance crucial in heat exchanger design for heat pump systems? Because corrosion can compromise the material durability, leading to leaks, reduced efficiency, and costly repairs. Selecting materials with high corrosion resistance ensures longevity and peak performance. Consider these key factors:

- Environmental Compatibility: Match materials to the working fluids and operating conditions to prevent chemical reactions.

- Material Strength: Choose durable metals like copper or stainless steel that withstand corrosion without losing structural integrity.

- Protective Coatings: Apply coatings or treatments to enhance corrosion resistance in aggressive environments.

- Maintenance Ease: Use materials that resist corrosion to reduce cleaning frequency and maintenance costs.

Prioritizing corrosion resistance keeps heat exchangers reliable, extending their service life and maintaining system efficiency.

Thermal Conductivity Factors

Material selection impacts more than just corrosion resistance; it also determines how efficiently heat is transferred in a heat exchanger. The key factor here is thermal conductivity, which measures how well a material conducts heat. Materials with high thermal conductivity, like copper and aluminum, facilitate better heat transfer, making your system more efficient. Conversely, materials with low thermal conductivity can hinder heat flow, reducing performance. When choosing materials, consider how thermal conductivity influences heat exchange rates and energy efficiency. Besides thermal conductivity, factors like weight, cost, and durability also matter, but prioritizing materials with good heat transfer properties ensures excellent system performance. Selecting the right materials based on their thermal conductivity is essential for designing effective, energy-efficient heat exchangers.

Structural Design Choices

When designing heat exchangers for heat pump systems, selecting the right materials and structural configurations is essential for peak performance and durability. Material selection impacts thermal efficiency and corrosion resistance, while structural configurations determine flow dynamics and maintenance ease. Consider these options:

- Material choices like copper, aluminum, or stainless steel for ideal thermal conductivity and corrosion resistance.

- Tube arrangements such as straight, U-tube, or multi-pass designs to enhance heat transfer.

- Fin configurations that improve surface area and airflow efficiency.

- Welded versus brazed joints to balance manufacturing complexity with durability.

Maintenance and Troubleshooting of Heat Exchangers

Regular maintenance is essential to keep heat exchangers in heat pump systems operating efficiently and reliably. To prevent issues, focus on corrosion prevention through regular inspections and applying protective coatings. Cleanings methods like chemical cleaning or gentle brushing remove dirt, grime, and mineral buildup that reduce heat transfer. Troubleshooting common problems involves checking for leaks, corrosion, or fouling. Here’s a quick overview:

| Issue | Cause | Solution |

|---|---|---|

| Corrosion | Moisture exposure | Use corrosion-resistant materials or coatings |

| Fouling | Dirt or mineral deposits | Schedule regular cleaning |

| Leaks | Physical damage | Repair or replace damaged parts |

Consistent upkeep guarantees your heat exchanger stays in top shape, preventing costly repairs. Additionally, understanding industry trends can help optimize maintenance schedules and improve system longevity.

Innovations and Advances in Heat Exchanger Technology

Recent advancements in heat exchanger technology have considerably improved efficiency and durability, making heat pump systems more reliable and cost-effective. You now benefit from innovations like nanofluid enhancements, which increase thermal conductivity and heat transfer capabilities. Additive manufacturing plays a pivotal role by enabling complex, optimized designs that were previously impossible, reducing material waste and improving performance. Key developments include:

- Integration of nanofluids to boost heat transfer rates.

- Use of additive manufacturing for lightweight, intricate heat exchanger structures.

- Enhanced corrosion resistance through advanced material coatings.

- Adoption of compact designs that maximize surface area while minimizing size.

These advances result in systems that operate more efficiently, last longer, and adapt better to varying operational conditions, pushing the boundaries of traditional heat exchanger performance.

The Impact of Heat Exchangers on Overall System Performance

Have you ever wondered how heat exchangers directly influence the efficiency and reliability of heat pump systems? Their performance hinges on thermal conductivity, which determines how effectively heat transfers between fluids. Higher thermal conductivity materials allow heat to flow more freely, boosting system efficiency. Additionally, flow optimization plays a pivotal role; well-designed heat exchangers ensure smooth fluid movement, minimizing pressure drops and maximizing heat transfer rates. Poor flow management can lead to uneven heating, energy loss, and system strain. When heat exchangers are optimized for thermal conductivity and flow, your system operates more reliably, consumes less energy, and delivers consistent heating or cooling. In short, their design directly impacts overall system performance, making them essential for efficient heat pump operation.

Frequently Asked Questions

How Do Different Refrigerants Affect Heat Exchanger Performance?

Different refrigerant types considerably impact heat exchanger performance because each refrigerant has unique thermal properties. Performance variations occur as some refrigerants transfer heat more efficiently, while others may cause increased pressure drops or corrosion. You need to take into account these differences when selecting refrigerants, as they directly influence system efficiency, durability, and maintenance needs. Understanding how refrigerant types affect performance helps optimize your heat pump system for better energy use and longevity.

What Are the Environmental Impacts of Various Heat Exchanger Materials?

You should consider the environmental impacts of heat exchanger materials, focusing on their recyclability and ecological footprint. Materials like copper and aluminum are highly recyclable, reducing waste and conserving resources. Conversely, plastics may have a higher ecological footprint due to limited recyclability and potential pollution. By choosing materials with better recyclability, you can lower the ecological footprint of heat exchangers, helping to minimize environmental harm and promote sustainable practices.

How Does Fouling Reduce Heat Exchanger Efficiency Over Time?

Fouling buildup acts like a stubborn shadow, steadily dimming your heat exchanger’s performance. As layers of dirt, scale, or biological growth accumulate, they create a barrier that hampers heat transfer. This efficiency decline means your system works harder, wasting energy and increasing costs. Over time, fouling reduces heat exchange effectiveness, making your system less reliable and more costly to operate—it’s like trying to breathe through a clogged straw.

What Safety Precautions Are Necessary During Heat Exchanger Maintenance?

During heat exchanger maintenance, you should prioritize safety by wearing personal protective equipment like gloves and goggles to prevent injuries. Always follow lockout procedures to guarantee the system is completely shut down and cannot accidentally start while you’re working. This combination helps protect you from potential hazards such as hot surfaces, sharp edges, or refrigerant leaks. Stay alert, follow safety protocols, and never bypass safety measures to keep yourself safe during maintenance.

Can Heat Exchangers Be Customized for Specific Heating or Cooling Needs?

Yes, heat exchangers can be customized for your specific heating or cooling needs. You can opt for custom design options that match your system’s requirements, ensuring ideal performance. Modular units offer flexibility, allowing you to expand or modify your setup as needed. By working with manufacturers who specialize in customization, you get tailored solutions that improve efficiency and meet your unique environmental demands.

Conclusion

Understanding heat exchangers helps you optimize your heat pump system’s performance. Imagine a homeowner noticing their heating feels inconsistent; by inspecting and maintaining the heat exchanger, they improve efficiency and save on energy costs. Whether upgrading materials or cleaning components, your efforts guarantee reliable heating and cooling. Staying informed about advances also means you can make smarter choices, keeping your system running smoothly and efficiently for years to come.